DIpil Das

What’s the Story?

Supply chain visibility involves more than just knowing what goods are coming in and going out: Supply chains need to be robust and resilient—looking toward the horizon and reacting rapidly to changes in supply and demand. Brands and retailers need to collect data not only from suppliers and customers but also from the suppliers' suppliers and the customers' customers, to effectively predict and respond to emerging events. Vast supply chains generate an enormous amount of data, and artificial intelligence/machine learning (AI/ML)-based platforms are needed to sort through this data, determine the priority of issues and respond to minor ones automatically. Emerging issues are triaged and monitored by a manager who can track those issues that require human intervention. We explore how intelligent supply chains go beyond the concept of a simple “control tower”—viewing and guiding incoming and outgoing goods—to include the automated analysis and management of emerging issues and tasks for ultimate supply chain visibility. This report is part of Coresight Research’s series of roundtable discussions and research reports, entitled The New Age of Customer-First Supply Chains, in which we present key insights into strategic areas in which brands and retailers can take action to build a resilient and profitable supply chain. Read our first three reports in the series:- Introduction—Four Pillars for Building a Resilient and Profitable Supply Chain

- Intelligent Demand Forecasting and On-Demand Manufacturing

- Customer-Centric Commercial Collaboration: The Importance of Data in Interconnected Supply Chains

Why It Matters

Having visibility is the first step in managing supply chains, which are the lifeblood of a retailer’s operations. In times of wide swings in demand, retailers need to make adjustments in real time to have the right products on the shelf at the right location at the right time. The availability of inventory has major implications for customer sentiment: If shoppers cannot acquire desired goods or acceptable substitutes, they can leave the store without making a purchase and document their experience in product reviews and on social media, affecting present and future revenues.Supply Chain Visibility: Coresight Research Analysis

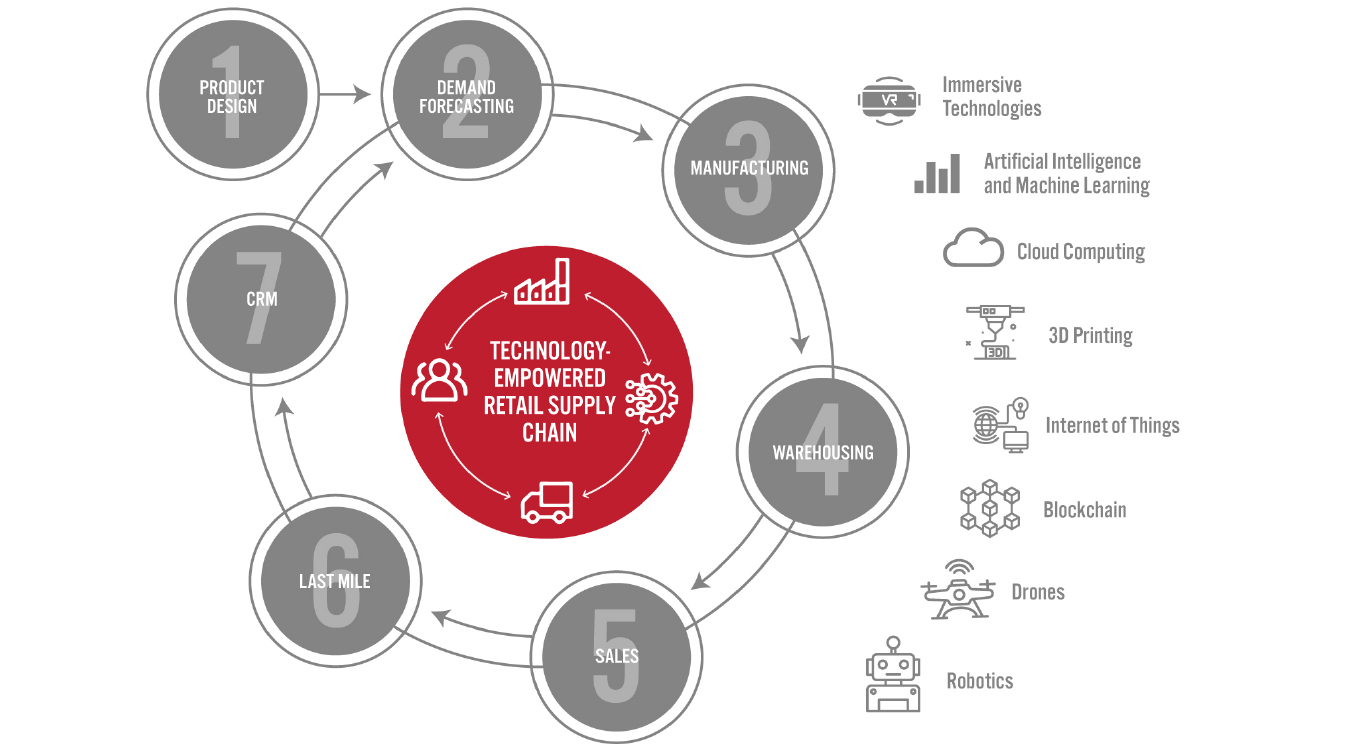

The Technology-Powered Retail Supply Chain Advanced supply chains run on a foundation of data, facilitated by AI and ML technologies that offer automation, enormous computing resources and the ability to find hidden, actionable insights within siloed, seemingly unconnected data, as well as the ability to make predictions and ensure that actions comply with a retailer’s or brand’s needs. Figure 1 illustrates that advanced supply chains share data in a virtuous circle—for example, customer data is fed into generating ideas for the development of new products and for optimizing inventory.Figure 1. The Technology-Powered Retail Supply Chain [caption id="attachment_134427" align="aligncenter" width="725"]

Source: Coresight Research[/caption]

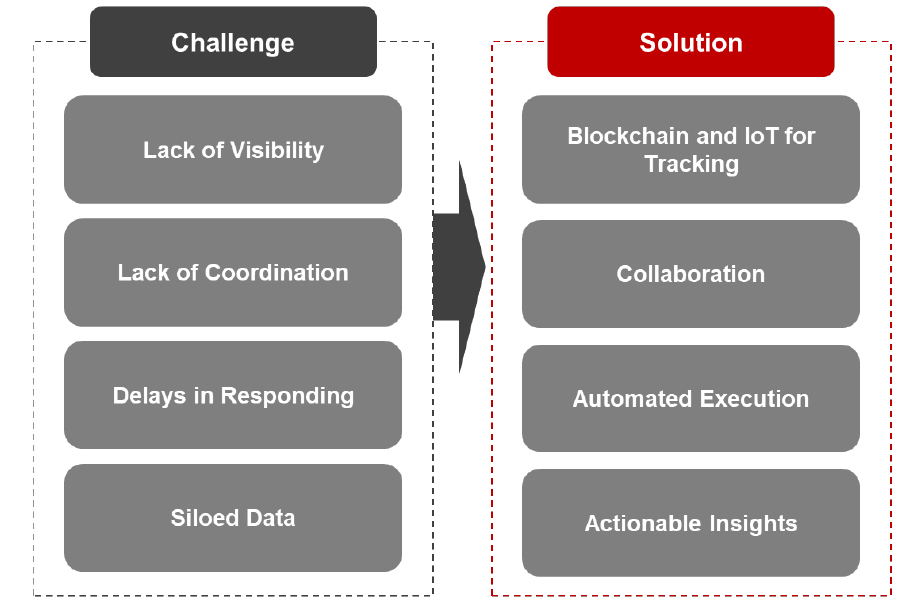

Intelligent, technology-powered supply chains provide solutions to many of the challenges that brands and retailers faced in traditional supply chains, as we outline in Figure 2.

Source: Coresight Research[/caption]

Intelligent, technology-powered supply chains provide solutions to many of the challenges that brands and retailers faced in traditional supply chains, as we outline in Figure 2.

- For more on the modern supply chain, see our separate report: Supply Chain Software—Shaking Off the Chains of the Past.

Figure 2. Challenges and Solutions in the Retail Supply Chain [caption id="attachment_134428" align="aligncenter" width="726"]

Source: Coresight Research[/caption]

Scope of Visibility

Brands and retailers need to achieve visibility into the supply chain due to increasing competition from e-commerce and physical retailers (many of which leverage data and new technologies), coupled with ever-changing consumer demand. Ensuring inventory availability is essential for retailers: Stockouts are the number-one reason that consumers will leave a store without purchasing anything, according to the Zebra Technologies’ 2021 Annual Shopper Vision Survey.

These challenges existed prior to Covid-19, but the pandemic brought even more dramatic shifts in consumer behavior, along with new challenges such as transportation bottlenecks, labor shortages and shortages of chips used in consumer electronics products and vehicles.

In prior linear supply chains, the scope of visibility was limited to between the supplier and retailer. To get the full picture, brands and retailers need to collect data from their suppliers’ suppliers and consumers, as shown in Figure 3. Moreover, data silos in the supply chain make it even more important that retailers and brands cultivate and leverage additional, external data sources. In some sectors, such as alcohol retailing, the sharing of data between retailers and suppliers is prohibited by law, forcing industry participants to cultivate their own data sources.

Source: Coresight Research[/caption]

Scope of Visibility

Brands and retailers need to achieve visibility into the supply chain due to increasing competition from e-commerce and physical retailers (many of which leverage data and new technologies), coupled with ever-changing consumer demand. Ensuring inventory availability is essential for retailers: Stockouts are the number-one reason that consumers will leave a store without purchasing anything, according to the Zebra Technologies’ 2021 Annual Shopper Vision Survey.

These challenges existed prior to Covid-19, but the pandemic brought even more dramatic shifts in consumer behavior, along with new challenges such as transportation bottlenecks, labor shortages and shortages of chips used in consumer electronics products and vehicles.

In prior linear supply chains, the scope of visibility was limited to between the supplier and retailer. To get the full picture, brands and retailers need to collect data from their suppliers’ suppliers and consumers, as shown in Figure 3. Moreover, data silos in the supply chain make it even more important that retailers and brands cultivate and leverage additional, external data sources. In some sectors, such as alcohol retailing, the sharing of data between retailers and suppliers is prohibited by law, forcing industry participants to cultivate their own data sources.

Figure 3. The Limited Scope of Traditional Supply Chain Visibility and the Extra Elements That Advanced Supply Chain Visibility Incorporates [caption id="attachment_134429" align="aligncenter" width="725"]

Source: Coresight Research[/caption]

Beyond the Control Tower: Functions of an Intelligent Supply Chain

The term “control tower” as a metaphor for the management of a supply chain is useful to a certain extent—and several software vendors market their products using this term—since supply chain managers guide goods from the manufacturer into the store and to the consumer, in much the same way as air-traffic controllers guide and orchestrate incoming and outgoing flights at an airport.

However, intelligent supply chain platforms do much more: They enable the automatic and human-driven solving of issues, both alone and in collaboration with other parties. For example, IBM’s Sterling Supply Chain Insights with Watson platform offers resolution rooms, a cloud-based collaboration app that creates a public and private virtual meeting rooms where colleagues can meet to discuss and resolve business problems.

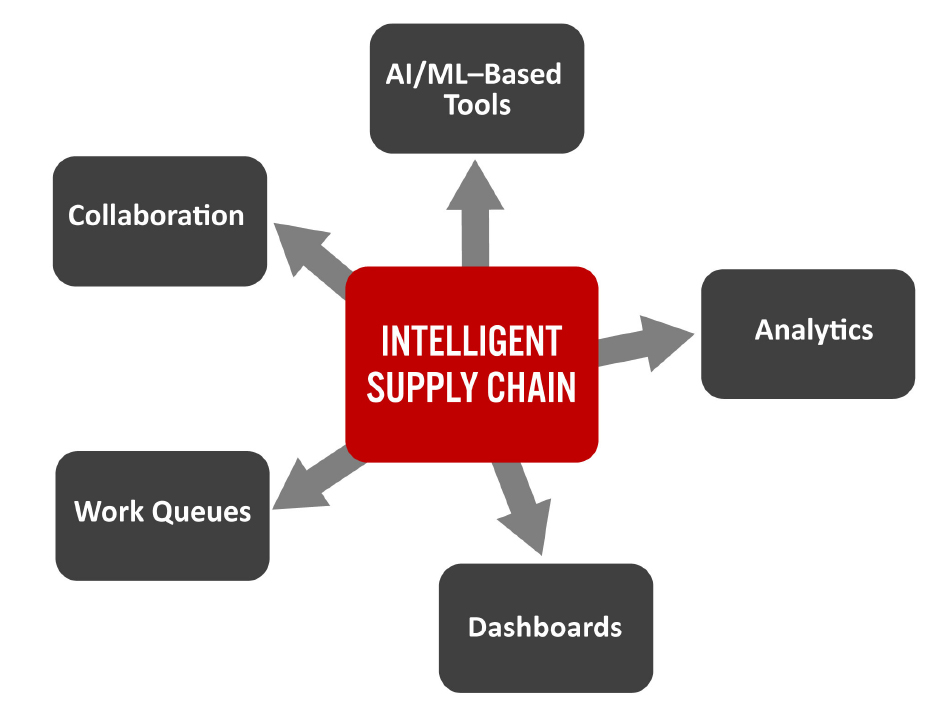

We summarize selected functions of intelligent supply chain platforms in Figure 4 and discuss each in detail below.

Source: Coresight Research[/caption]

Beyond the Control Tower: Functions of an Intelligent Supply Chain

The term “control tower” as a metaphor for the management of a supply chain is useful to a certain extent—and several software vendors market their products using this term—since supply chain managers guide goods from the manufacturer into the store and to the consumer, in much the same way as air-traffic controllers guide and orchestrate incoming and outgoing flights at an airport.

However, intelligent supply chain platforms do much more: They enable the automatic and human-driven solving of issues, both alone and in collaboration with other parties. For example, IBM’s Sterling Supply Chain Insights with Watson platform offers resolution rooms, a cloud-based collaboration app that creates a public and private virtual meeting rooms where colleagues can meet to discuss and resolve business problems.

We summarize selected functions of intelligent supply chain platforms in Figure 4 and discuss each in detail below.

Figure 4. Overview of Selected Intelligent Supply Chain Functions [caption id="attachment_134430" align="aligncenter" width="725"]

Source: Coresight Research[/caption]

AI/ML-Based Tools

These tools perform the basis of an intelligent supply chain platform, which leverage the technologies’ inherent strengths in the following areas:

Source: Coresight Research[/caption]

AI/ML-Based Tools

These tools perform the basis of an intelligent supply chain platform, which leverage the technologies’ inherent strengths in the following areas:

- Automating routine tasks

- Applying substantial computing resources to analyzing data

- Making predictions using the appropriate model

- Bridging the gap among siloed data

- Finding hidden relationships among data

- Descriptive: Understanding what has happened

- Predictive: Determining what is expected to happen

- Prescriptive: Finding the best course of corrective action

- Please see our recent report on customer-centric commercial collaboration.

- Improved efficiency. Measuring and quantifying elements of supply chains is the first step in managing and optimizing them. Optimizing supply chains brings benefits in the use of working capital (since inventory consumes working capital), in addition to reducing the footprint of inventory and the need for markdowns due to excess inventory. Furthermore, knowing the exact location and quantity of inventory enables brands and retailers to deploy it to the proper location to maximize revenues and margins.

- Reduced lead times. Tracking items in transit and measuring transit times enables brands and retailers to predict and ensure inventory availability; they can engage other suppliers or deploy inventory from other locations if shipments are delayed.

- Reduced food waste. Grocers deal with many unique challenges stemming from goods that have a limited shelf life. Having visibility into the location and quantity of time-sensitive inventory helps grocers make decisions on allocation and pricing.

- Guaranteed authenticity and compliance. The transfer of goods can involve a great deal of regulation and documentation, and a robust supply chain platform can provide a robust audit trail and data that document the contents and history of goods and raw materials, including where they have been and in whose custody, providing clear documentation on the provenance and authenticity of goods and their component parts.

- Improved operations and profitability. In addition to efficiency, a strong overview of goods in the supply chain can optimize inventory availability and reduce stockouts, thus enhancing customer satisfaction and increasing revenues. Similarly, a clear view of inventory enables retailers to sell down to the last item, protecting pricing and reducing the need for excessive discounting, which boosts margins.

Figure 5. Selected Software Vendors for Supply Chain Visibility [wpdatatable id=1343 table_view=regular]

Source: Apps Run the World/company reports/Owler/Xe.com/Coresight Research There are also innovators engaged in supply chain intelligence: Alloy.ai offers demand intelligence, inventory intelligence and demand planning; and Inspectorio and R3 enable collaboration.

What We Think

The pandemic has brought supply chain management to the company board room, as a key tool driving customer satisfaction and, as a result, revenues and margins. Consumer demand continues to shift, and other events such as labor shortages and shipping bottlenecks are making supply chain management extremely challenging. Brands and retailers need to have visibility into what inventory they have and employ powerful tools—both human and machine-powered—to stay on top of emerging events and make product and inventory decisions based on all available data in real time. Intelligent supply chain management platforms, fueled by AI and ML technologies, enable brands and retailers to successfully gain visibility into complex global supply chains. Implications for Brands/Retailers- Brands need supply chain visibility to understand where their products are, and in what quantity, on a real-time basis, to best meet consumer demand.

- Retailers need real-time intelligence on the status of goods, including potential shipping delays, to make allocation and inventory decisions to enhance consumer satisfaction.

- The existence of ongoing shortages implies that there are many opportunities for software vendors to offer intelligent supply chain management tools.

- AI/ML capabilities continue to advance, presenting opportunities for technology developers.

- Intelligent supply chain platforms incorporate multiple functional areas—including analytics, forecasting and fostering collaboration—which offer opportunities for specialized technology providers.