Nitheesh NH

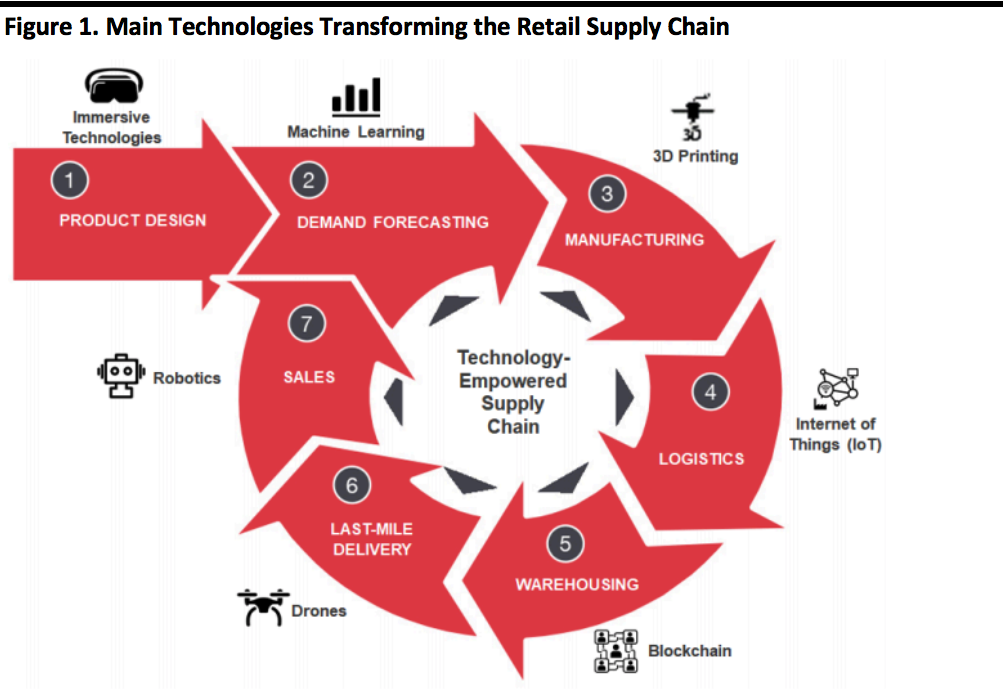

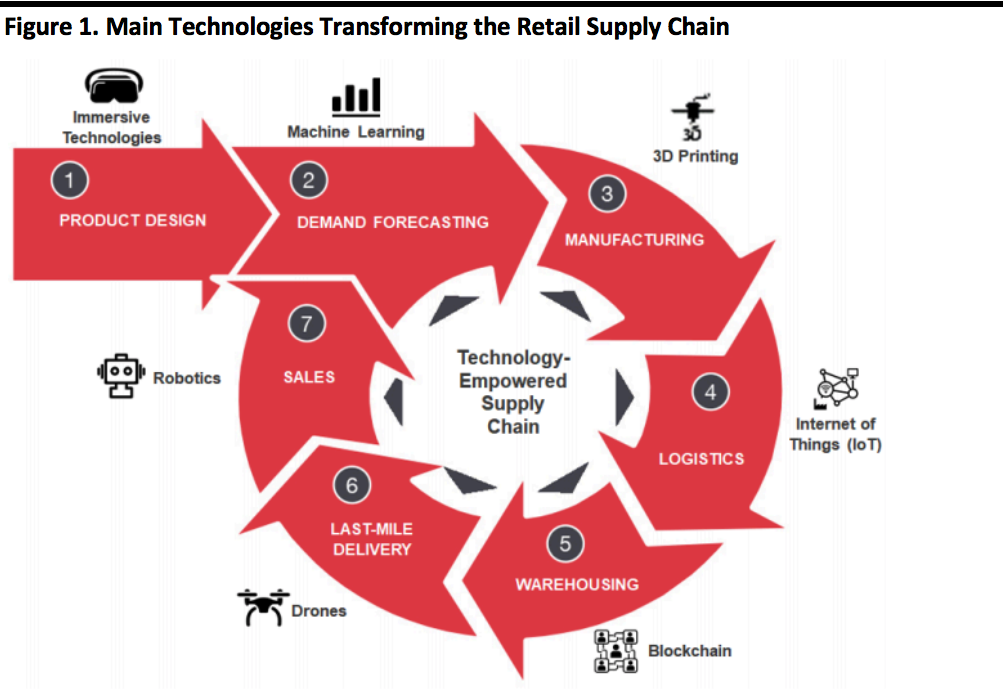

Our Supply Chain Briefing series looks at how technology is transforming the various stages of the retail supply chain. Below, we illustrate the seven major components of the retail supply chain and some of the technologies that can support processes at various stages—from product design to end consumer.

[caption id="attachment_100430" align="aligncenter" width="700"] Source: Coresight Research[/caption]

Supply Chain Simplification - An Ongoing Process

The supply chain is typically complex, incorporating various parties along product design, demand forecasting, manufacturing, logistics, warehousing, last-mile delivery and sales. In 2016, DHL surveyed 350 supply chain and operations professionals in five major regions around the world. According the survey, 32% of respondents said they operate more than 10 distinct supply chains while 40% of said they have two to five different supply chains. Operating an overly complicated supply chain—or a variety of supply chains—can generate high costs and waste resources.

Companies are taking a variety of approaches to streamlining supply chains, such as consolidating vendors, unifying data systems and streamlining distribution channels by selling directly to consumers.

We are also seeing companies rely increasingly on digital technologies, such as using Big Data and machine learning analytics tools for predictive analysis, embracing robotics and autonomous warehouses and leveraging cloud system to integrate digital infrastructure.

In addition to the obvious cost-savings and reduction in operational issues, simplifying the supply chain can help companies improve the customer experience by ensuring the right product is available at the right location and at the right time through a more accurate demand forecasting and an improved distribution.

For example, sports apparel company Under Armour began working on its supply chain in 2017 after seeing a slowdown in sales growth and rising operational costs. By simplifying programming tools, programming languages and software, including unifying its global enterprise resources planning (ERP) system, Under Armour cut inventory by $330 million and increased its gross margin by 170 basis points (bps) to 46.5% in 2Q19 compared to the previous year. According to the company, 110 bps of the 170-bps gain was due to supply chain efforts.

How Are Companies Streamlining Supply Chains?

Below, we note four ways brands and retailers have streamlined supply chains.

1. Consolidating Suppliers

Large brand owners may source from thousands of suppliers. For example, Procter & Gamble has around 50,000 suppliers. Consolidating suppliers allows retailers to focus on selected ones or even build direct connections with the manufactures.

Consolidation lets retailers increase purchasing power as they orders from fewer suppliers, and helps them maintain better and more productive relationships as there are fewer vendors and manufacturers to manage.

2. Using Big Data and Machine Learning Analytics Tools

Many brands and retailers make merchandise decisions and forecast demand using historical average and time series models, which require data sets be linear and have consistent variations. But in a social media and digital era, there are numerous nonhistorical, nonlinear and complex variables that can affect consumer behavior, such as influencer and peer reviews. Traditional forecasting models don’t capture these variables, so miss the opportunity to capture data that can make forecasts far more accurate.

To tap into the insights they may have been missing, some companies are leveraging machine learning to process the often massive amounts of data they have on consumer behavior to better predict demand. Machine learning can process much larger numbers of factors from multiple data sources, determine the factors that are impactful and needs far less manual data manipulation.

By adding machine learning into the decision-making mix, companies can make demand forecast less difficult, more accurately forecast demand and allocate resources more efficiently.

One example of a companies using machine learning to improve in supply chain operations is Nestlé work with data analytics company SAS to help with demand forecasting. SAS’s machine learning empowered technology promises to help Nestlé to more accurately predict demand and reduce excess inventory.

3. Embracing Robotics and Autonomous Warehouses

Warehouses and distribution centers that rely on labor-intensive manual process, such as manual order checking and replenishment, are more prone to error. Autonomous robots in distribution centers increase picking accuracy, reduce labor hours to boost productivity. This is why many companies are embracing robotics and other technologies to manage warehouse and distribution center processes.

According to market intelligence firm Tractica, global shipments of warehousing and logistics robots will reach 938,000 units by 2022—almost five times the 194,000 units shipped in 2018.

Some of the popular technologies include: automated guided vehicles (AGVs), portable robots that usually use magnetic strips or wires to navigate and can transport heavy items; and, autonomous mobile robots (AMRs), a smart version of an AGV that uses laser scanners, build-in sensors, cameras to navigate, detect surroundings and choose the most efficient route between points.

Here are some companies using robotics and automation in the supply chain:

Source: Coresight Research[/caption]

Supply Chain Simplification - An Ongoing Process

The supply chain is typically complex, incorporating various parties along product design, demand forecasting, manufacturing, logistics, warehousing, last-mile delivery and sales. In 2016, DHL surveyed 350 supply chain and operations professionals in five major regions around the world. According the survey, 32% of respondents said they operate more than 10 distinct supply chains while 40% of said they have two to five different supply chains. Operating an overly complicated supply chain—or a variety of supply chains—can generate high costs and waste resources.

Companies are taking a variety of approaches to streamlining supply chains, such as consolidating vendors, unifying data systems and streamlining distribution channels by selling directly to consumers.

We are also seeing companies rely increasingly on digital technologies, such as using Big Data and machine learning analytics tools for predictive analysis, embracing robotics and autonomous warehouses and leveraging cloud system to integrate digital infrastructure.

In addition to the obvious cost-savings and reduction in operational issues, simplifying the supply chain can help companies improve the customer experience by ensuring the right product is available at the right location and at the right time through a more accurate demand forecasting and an improved distribution.

For example, sports apparel company Under Armour began working on its supply chain in 2017 after seeing a slowdown in sales growth and rising operational costs. By simplifying programming tools, programming languages and software, including unifying its global enterprise resources planning (ERP) system, Under Armour cut inventory by $330 million and increased its gross margin by 170 basis points (bps) to 46.5% in 2Q19 compared to the previous year. According to the company, 110 bps of the 170-bps gain was due to supply chain efforts.

How Are Companies Streamlining Supply Chains?

Below, we note four ways brands and retailers have streamlined supply chains.

1. Consolidating Suppliers

Large brand owners may source from thousands of suppliers. For example, Procter & Gamble has around 50,000 suppliers. Consolidating suppliers allows retailers to focus on selected ones or even build direct connections with the manufactures.

Consolidation lets retailers increase purchasing power as they orders from fewer suppliers, and helps them maintain better and more productive relationships as there are fewer vendors and manufacturers to manage.

2. Using Big Data and Machine Learning Analytics Tools

Many brands and retailers make merchandise decisions and forecast demand using historical average and time series models, which require data sets be linear and have consistent variations. But in a social media and digital era, there are numerous nonhistorical, nonlinear and complex variables that can affect consumer behavior, such as influencer and peer reviews. Traditional forecasting models don’t capture these variables, so miss the opportunity to capture data that can make forecasts far more accurate.

To tap into the insights they may have been missing, some companies are leveraging machine learning to process the often massive amounts of data they have on consumer behavior to better predict demand. Machine learning can process much larger numbers of factors from multiple data sources, determine the factors that are impactful and needs far less manual data manipulation.

By adding machine learning into the decision-making mix, companies can make demand forecast less difficult, more accurately forecast demand and allocate resources more efficiently.

One example of a companies using machine learning to improve in supply chain operations is Nestlé work with data analytics company SAS to help with demand forecasting. SAS’s machine learning empowered technology promises to help Nestlé to more accurately predict demand and reduce excess inventory.

3. Embracing Robotics and Autonomous Warehouses

Warehouses and distribution centers that rely on labor-intensive manual process, such as manual order checking and replenishment, are more prone to error. Autonomous robots in distribution centers increase picking accuracy, reduce labor hours to boost productivity. This is why many companies are embracing robotics and other technologies to manage warehouse and distribution center processes.

According to market intelligence firm Tractica, global shipments of warehousing and logistics robots will reach 938,000 units by 2022—almost five times the 194,000 units shipped in 2018.

Some of the popular technologies include: automated guided vehicles (AGVs), portable robots that usually use magnetic strips or wires to navigate and can transport heavy items; and, autonomous mobile robots (AMRs), a smart version of an AGV that uses laser scanners, build-in sensors, cameras to navigate, detect surroundings and choose the most efficient route between points.

Here are some companies using robotics and automation in the supply chain:

Source: Coresight Research[/caption]

Supply Chain Simplification - An Ongoing Process

The supply chain is typically complex, incorporating various parties along product design, demand forecasting, manufacturing, logistics, warehousing, last-mile delivery and sales. In 2016, DHL surveyed 350 supply chain and operations professionals in five major regions around the world. According the survey, 32% of respondents said they operate more than 10 distinct supply chains while 40% of said they have two to five different supply chains. Operating an overly complicated supply chain—or a variety of supply chains—can generate high costs and waste resources.

Companies are taking a variety of approaches to streamlining supply chains, such as consolidating vendors, unifying data systems and streamlining distribution channels by selling directly to consumers.

We are also seeing companies rely increasingly on digital technologies, such as using Big Data and machine learning analytics tools for predictive analysis, embracing robotics and autonomous warehouses and leveraging cloud system to integrate digital infrastructure.

In addition to the obvious cost-savings and reduction in operational issues, simplifying the supply chain can help companies improve the customer experience by ensuring the right product is available at the right location and at the right time through a more accurate demand forecasting and an improved distribution.

For example, sports apparel company Under Armour began working on its supply chain in 2017 after seeing a slowdown in sales growth and rising operational costs. By simplifying programming tools, programming languages and software, including unifying its global enterprise resources planning (ERP) system, Under Armour cut inventory by $330 million and increased its gross margin by 170 basis points (bps) to 46.5% in 2Q19 compared to the previous year. According to the company, 110 bps of the 170-bps gain was due to supply chain efforts.

How Are Companies Streamlining Supply Chains?

Below, we note four ways brands and retailers have streamlined supply chains.

1. Consolidating Suppliers

Large brand owners may source from thousands of suppliers. For example, Procter & Gamble has around 50,000 suppliers. Consolidating suppliers allows retailers to focus on selected ones or even build direct connections with the manufactures.

Consolidation lets retailers increase purchasing power as they orders from fewer suppliers, and helps them maintain better and more productive relationships as there are fewer vendors and manufacturers to manage.

2. Using Big Data and Machine Learning Analytics Tools

Many brands and retailers make merchandise decisions and forecast demand using historical average and time series models, which require data sets be linear and have consistent variations. But in a social media and digital era, there are numerous nonhistorical, nonlinear and complex variables that can affect consumer behavior, such as influencer and peer reviews. Traditional forecasting models don’t capture these variables, so miss the opportunity to capture data that can make forecasts far more accurate.

To tap into the insights they may have been missing, some companies are leveraging machine learning to process the often massive amounts of data they have on consumer behavior to better predict demand. Machine learning can process much larger numbers of factors from multiple data sources, determine the factors that are impactful and needs far less manual data manipulation.

By adding machine learning into the decision-making mix, companies can make demand forecast less difficult, more accurately forecast demand and allocate resources more efficiently.

One example of a companies using machine learning to improve in supply chain operations is Nestlé work with data analytics company SAS to help with demand forecasting. SAS’s machine learning empowered technology promises to help Nestlé to more accurately predict demand and reduce excess inventory.

3. Embracing Robotics and Autonomous Warehouses

Warehouses and distribution centers that rely on labor-intensive manual process, such as manual order checking and replenishment, are more prone to error. Autonomous robots in distribution centers increase picking accuracy, reduce labor hours to boost productivity. This is why many companies are embracing robotics and other technologies to manage warehouse and distribution center processes.

According to market intelligence firm Tractica, global shipments of warehousing and logistics robots will reach 938,000 units by 2022—almost five times the 194,000 units shipped in 2018.

Some of the popular technologies include: automated guided vehicles (AGVs), portable robots that usually use magnetic strips or wires to navigate and can transport heavy items; and, autonomous mobile robots (AMRs), a smart version of an AGV that uses laser scanners, build-in sensors, cameras to navigate, detect surroundings and choose the most efficient route between points.

Here are some companies using robotics and automation in the supply chain:

Source: Coresight Research[/caption]

Supply Chain Simplification - An Ongoing Process

The supply chain is typically complex, incorporating various parties along product design, demand forecasting, manufacturing, logistics, warehousing, last-mile delivery and sales. In 2016, DHL surveyed 350 supply chain and operations professionals in five major regions around the world. According the survey, 32% of respondents said they operate more than 10 distinct supply chains while 40% of said they have two to five different supply chains. Operating an overly complicated supply chain—or a variety of supply chains—can generate high costs and waste resources.

Companies are taking a variety of approaches to streamlining supply chains, such as consolidating vendors, unifying data systems and streamlining distribution channels by selling directly to consumers.

We are also seeing companies rely increasingly on digital technologies, such as using Big Data and machine learning analytics tools for predictive analysis, embracing robotics and autonomous warehouses and leveraging cloud system to integrate digital infrastructure.

In addition to the obvious cost-savings and reduction in operational issues, simplifying the supply chain can help companies improve the customer experience by ensuring the right product is available at the right location and at the right time through a more accurate demand forecasting and an improved distribution.

For example, sports apparel company Under Armour began working on its supply chain in 2017 after seeing a slowdown in sales growth and rising operational costs. By simplifying programming tools, programming languages and software, including unifying its global enterprise resources planning (ERP) system, Under Armour cut inventory by $330 million and increased its gross margin by 170 basis points (bps) to 46.5% in 2Q19 compared to the previous year. According to the company, 110 bps of the 170-bps gain was due to supply chain efforts.

How Are Companies Streamlining Supply Chains?

Below, we note four ways brands and retailers have streamlined supply chains.

1. Consolidating Suppliers

Large brand owners may source from thousands of suppliers. For example, Procter & Gamble has around 50,000 suppliers. Consolidating suppliers allows retailers to focus on selected ones or even build direct connections with the manufactures.

Consolidation lets retailers increase purchasing power as they orders from fewer suppliers, and helps them maintain better and more productive relationships as there are fewer vendors and manufacturers to manage.

2. Using Big Data and Machine Learning Analytics Tools

Many brands and retailers make merchandise decisions and forecast demand using historical average and time series models, which require data sets be linear and have consistent variations. But in a social media and digital era, there are numerous nonhistorical, nonlinear and complex variables that can affect consumer behavior, such as influencer and peer reviews. Traditional forecasting models don’t capture these variables, so miss the opportunity to capture data that can make forecasts far more accurate.

To tap into the insights they may have been missing, some companies are leveraging machine learning to process the often massive amounts of data they have on consumer behavior to better predict demand. Machine learning can process much larger numbers of factors from multiple data sources, determine the factors that are impactful and needs far less manual data manipulation.

By adding machine learning into the decision-making mix, companies can make demand forecast less difficult, more accurately forecast demand and allocate resources more efficiently.

One example of a companies using machine learning to improve in supply chain operations is Nestlé work with data analytics company SAS to help with demand forecasting. SAS’s machine learning empowered technology promises to help Nestlé to more accurately predict demand and reduce excess inventory.

3. Embracing Robotics and Autonomous Warehouses

Warehouses and distribution centers that rely on labor-intensive manual process, such as manual order checking and replenishment, are more prone to error. Autonomous robots in distribution centers increase picking accuracy, reduce labor hours to boost productivity. This is why many companies are embracing robotics and other technologies to manage warehouse and distribution center processes.

According to market intelligence firm Tractica, global shipments of warehousing and logistics robots will reach 938,000 units by 2022—almost five times the 194,000 units shipped in 2018.

Some of the popular technologies include: automated guided vehicles (AGVs), portable robots that usually use magnetic strips or wires to navigate and can transport heavy items; and, autonomous mobile robots (AMRs), a smart version of an AGV that uses laser scanners, build-in sensors, cameras to navigate, detect surroundings and choose the most efficient route between points.

Here are some companies using robotics and automation in the supply chain:

- JD.com unveiled a robotic warehouse in 2018 reported to have only four staff, but in which robots process over 200,000 orders daily.

- In May 2018, Kroger teamed up with UK online-only retailer Ocado to build Kroger’s first automated robot warehouse in Monroe, Ohio. The warehouse is expected to be able to fill an average grocery order of 50 items in six to seven minutes.