albert Chan

Source: Coresight Research[/caption]

Source: Coresight Research[/caption]

What is Digital Twin Technology?

A “digital twin” is a virtual replica of a physical product, process, or system. It acts as a bridge between physical and digital worlds by using sensors to collect real-time data about a physical item. This data is then used to create a digital duplicate of the item, allowing it to be better understood, analyzed, manipulated or optimized.

Digital twin technology can help retailers improve the customer experience by better understanding customer needs, developing enhancements to existing products, improving operations, enhancing service levels – and even driving innovation.

For example, General Electric (GE) uses digital twins to improve its wind turbines. For every physical asset, there is a virtual copy (a digital twin) in the cloud: GE uses data collected to modify the configuration new wind turbines before they are built. The company hopes to increase efficiency 20% by analyzing data from each turbine fed to its digital twin.

Software to create digital twins is already available, such as Seebo, an end-to-end digital twin platform that helps manufacturers develop a digital model for simulations to verify functionality and analyze a product’s actual use and behavior. Platforms such as Seebo can help companies deploy a digital twin of a product in just 2-3 months.

[caption id="attachment_93453" align="aligncenter" width="700"] Digital twin software Seebo

Digital twin software SeeboSource: Seebo[/caption]

Business Case for Digital Twin Technology

The retail industry has a rising appetite for digital twins given the need to track products along the supply chain, and the constant pressure to reduce cost and drive out inefficiency.

The market size of digital twin technology is anticipated to exceed $20 billion by 2025, according to research and consulting firm Global Market Insights. The machine and equipment health monitoring segment is anticipated to dominate the market between 2018 and 2025.

How Supply Chain Operations Can Leverage Digital Twin Technology

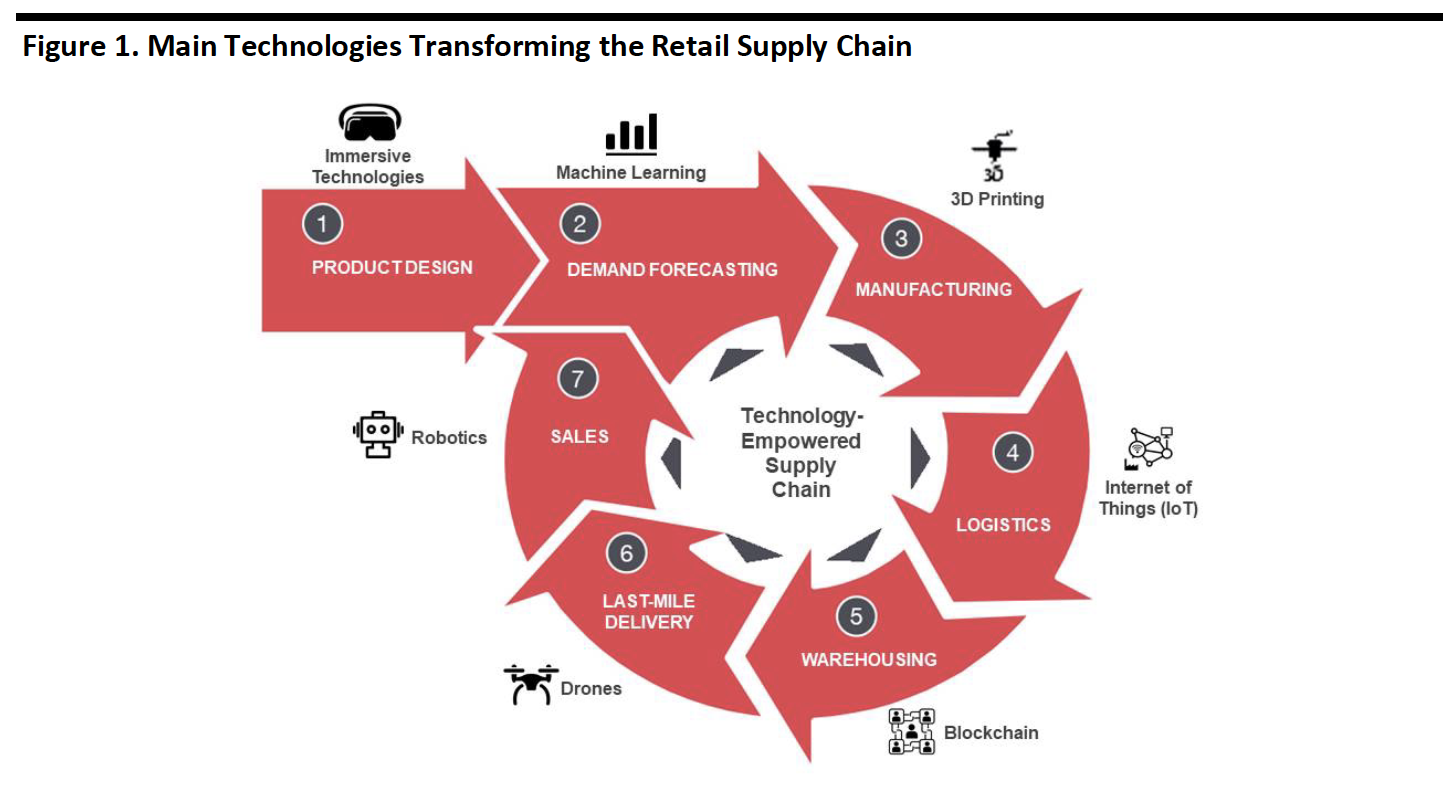

Digital twin technology offers retailers many benefits at various stages of the supply chain, including:

- Enhanced visibility: The technology allows companies to create a complete digital copy of a product’s journey from design and development through end of life, giving greater visibility into systems and processes.

- Predictive maintenance: Digital twins give the ability to monitor operations, increasing the ability to predict possible failures.

- Respond more quickly to consumer demand: Digital twins allow companies to test and monitor physical products without needing to access the real object, enabling faster response to changing customer demand.

- Reduced cost: Digital twins reduce costs by significantly lowering the chances of late-stage design changes. It also allows product engineers to test and update digital models and reduce the chance of errors.

How Consumer Goods and Retail Can Benefit from Digital Twins

Digital twin technology has already been tested in fast moving consumer goods (FMCG) manufacturing. For example, Microsoft has been working with Unilever to set up eight digital twins of the company’s manufacturing facilities to streamline the soap production process globally. This can help Unilever create a digital duplicate of every machine and process, delivering increased visibility across its manufacturing processes.

Digital twins can also play a role in tracking retail products through the supply chain. With the help of connected sensors attached to products, businesses can keep track of products as they are sourced, purchased and consumed, generating data for digital twins. From discounts applied along the supply chain to the stores, information is stored digitally and can offer retailers insights to improve the customer experience. French supermarket Intermarché uses data from IoT-enabled shelves and sales systems to create digital twins of physical stores so store managers get real-time insights on stock and can test different store layouts.

The Outlook for Digital Twin Technology in Retail

While the concept of the digital twins has been known in manufacturing for some time, it is still relatively new to consumer retail. But we see vast potential as the industry moves into the era of the Internet of Things: We expect the retail and consumer goods segment to embrace digital twin technology to better understand the changing needs of consumers and customize products, services and operations.