DIpil Das

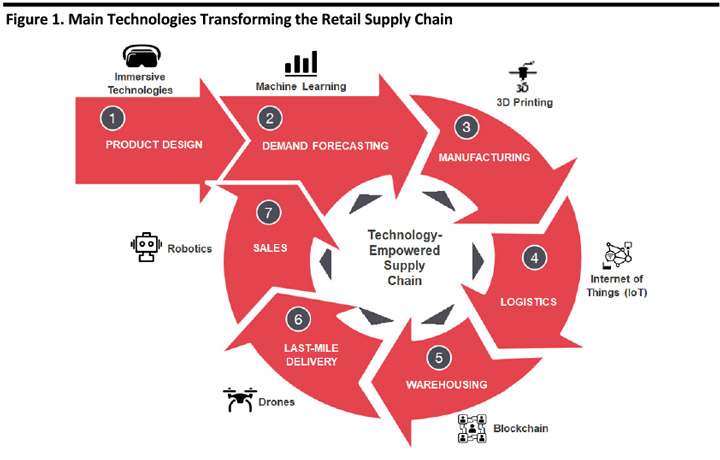

In our weekly series Supply Chain Briefing, we discuss how technology is transforming the various stages in the retail supply chain, including product design, demand forecasting, manufacturing, logistics, warehousing, last-mile delivery and sales.

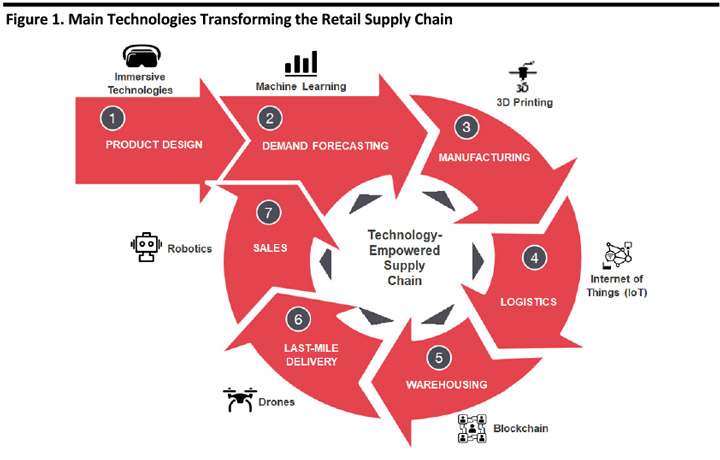

Below, we illustrate the seven major components of a retail supply chain, and some of the technologies that can support processes at various stages – from product design to end consumer.

[caption id="attachment_89934" align="aligncenter" width="720"] Source: Coresight Research[/caption]

3D printing — or addictive manufacturing (AM) — in its simplest form can be described as a sequential building of a three-dimensional solid object through successive injection of materials with the help of a digital model and 3D printers. Industries including consumer goods are using 3D printing to increase supply chain efficiency. According to the 2018 Supply Chain Innovation Survey by supply chain management company Kenko, 35% of companies planned to invest in 3D printing in 2018, compared with just 22% in 2017.

Below, we outline the industrial applications of 3D printing and the benefits that 3D printing can bring to different companies.

3D Printing Streamlines Product Design and Improves Workflow

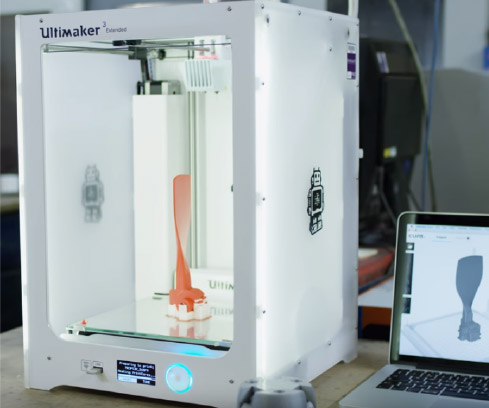

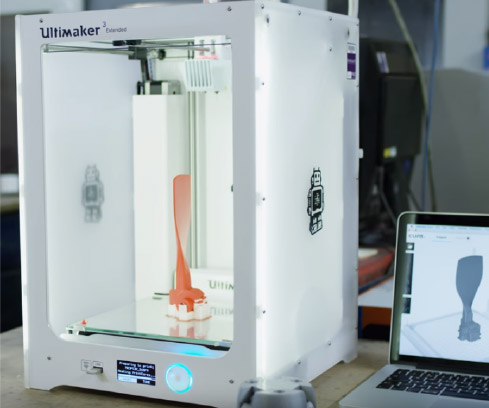

Companies in various industries are using 3D printing to streamline product design and improve product research workflow. Sylatech, a design and manufacturing company, used 3D printers from Ultimaker to speed the prototyping process for metal parts, cutting the time from weeks to five days, and reducing product design modification costs from £500 to roughly £10.

[caption id="attachment_89935" align="aligncenter" width="489"]

Source: Coresight Research[/caption]

3D printing — or addictive manufacturing (AM) — in its simplest form can be described as a sequential building of a three-dimensional solid object through successive injection of materials with the help of a digital model and 3D printers. Industries including consumer goods are using 3D printing to increase supply chain efficiency. According to the 2018 Supply Chain Innovation Survey by supply chain management company Kenko, 35% of companies planned to invest in 3D printing in 2018, compared with just 22% in 2017.

Below, we outline the industrial applications of 3D printing and the benefits that 3D printing can bring to different companies.

3D Printing Streamlines Product Design and Improves Workflow

Companies in various industries are using 3D printing to streamline product design and improve product research workflow. Sylatech, a design and manufacturing company, used 3D printers from Ultimaker to speed the prototyping process for metal parts, cutting the time from weeks to five days, and reducing product design modification costs from £500 to roughly £10.

[caption id="attachment_89935" align="aligncenter" width="489"] Sylatech using 3D printers to speed product prototyping

Sylatech using 3D printers to speed product prototyping

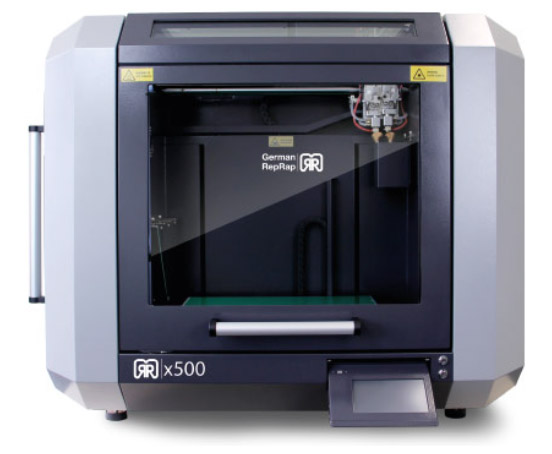

Source: Sylatech [/caption] BMW has been using the x500 3D printer from German RepRap to produce car part prototypes, helping the company meet deadlines, reduce costs and enabling it to implement different ideas for end products faster. [caption id="attachment_89936" align="aligncenter" width="480"] German RepRap’s x500 3D printer

German RepRap’s x500 3D printer

Source: German RepRap [/caption] 3D Printing Shortens Production Time Apart from speeding up product development and design, 3D printing also shortens production time. Adidas announced plans to extend its line of Futurecraft 4D sneakers in collaboration with Carbon, a 3D printing company based in Silicon Valley. Carbon claims that, with further advances in 3D printing, the production time for a single midsole for Adidas Futurecraft 4D sneakers could be cut to 20 minutes from 90. [caption id="attachment_89937" align="aligncenter" width="720"] Adidas Futurecraft 4D Sneakers

Adidas Futurecraft 4D Sneakers

Source: Adidas [/caption] 3D Printing Enables Customized Products Kolmar Korea, a Korean cosmetics manufacturer, announced in early March 2019 it successfully used 3D printing technology to create a cream that could be molded into different shapes. The company is using the technology to develop customized 3D-printed make-up products such as lipsticks and compact powder. Kolmar said that 3D printing enables the production of highly customized products and can print product designs with different ingredients without using molds. [caption id="attachment_89938" align="aligncenter" width="720"] Kolmar Korea’s 3D-printed skin care cream

Kolmar Korea’s 3D-printed skin care cream

Source: Kolmar Korea [/caption] Key Insights and Implications for Retailers 3D printing technology brings benefits to brands and retailers in various stages of the supply chain by speeding product design, shortening production lead time and making it possible to produce customized products at affordable cost. With further advances in 3D printing technology and increased accessibility and affordability, we believe 3D printing is a promising technology that offers many potential benefits to retailers from a supply chain perspective.

Source: Coresight Research[/caption]

3D printing — or addictive manufacturing (AM) — in its simplest form can be described as a sequential building of a three-dimensional solid object through successive injection of materials with the help of a digital model and 3D printers. Industries including consumer goods are using 3D printing to increase supply chain efficiency. According to the 2018 Supply Chain Innovation Survey by supply chain management company Kenko, 35% of companies planned to invest in 3D printing in 2018, compared with just 22% in 2017.

Below, we outline the industrial applications of 3D printing and the benefits that 3D printing can bring to different companies.

3D Printing Streamlines Product Design and Improves Workflow

Companies in various industries are using 3D printing to streamline product design and improve product research workflow. Sylatech, a design and manufacturing company, used 3D printers from Ultimaker to speed the prototyping process for metal parts, cutting the time from weeks to five days, and reducing product design modification costs from £500 to roughly £10.

[caption id="attachment_89935" align="aligncenter" width="489"]

Source: Coresight Research[/caption]

3D printing — or addictive manufacturing (AM) — in its simplest form can be described as a sequential building of a three-dimensional solid object through successive injection of materials with the help of a digital model and 3D printers. Industries including consumer goods are using 3D printing to increase supply chain efficiency. According to the 2018 Supply Chain Innovation Survey by supply chain management company Kenko, 35% of companies planned to invest in 3D printing in 2018, compared with just 22% in 2017.

Below, we outline the industrial applications of 3D printing and the benefits that 3D printing can bring to different companies.

3D Printing Streamlines Product Design and Improves Workflow

Companies in various industries are using 3D printing to streamline product design and improve product research workflow. Sylatech, a design and manufacturing company, used 3D printers from Ultimaker to speed the prototyping process for metal parts, cutting the time from weeks to five days, and reducing product design modification costs from £500 to roughly £10.

[caption id="attachment_89935" align="aligncenter" width="489"] Sylatech using 3D printers to speed product prototyping

Sylatech using 3D printers to speed product prototyping Source: Sylatech [/caption] BMW has been using the x500 3D printer from German RepRap to produce car part prototypes, helping the company meet deadlines, reduce costs and enabling it to implement different ideas for end products faster. [caption id="attachment_89936" align="aligncenter" width="480"]

German RepRap’s x500 3D printer

German RepRap’s x500 3D printer Source: German RepRap [/caption] 3D Printing Shortens Production Time Apart from speeding up product development and design, 3D printing also shortens production time. Adidas announced plans to extend its line of Futurecraft 4D sneakers in collaboration with Carbon, a 3D printing company based in Silicon Valley. Carbon claims that, with further advances in 3D printing, the production time for a single midsole for Adidas Futurecraft 4D sneakers could be cut to 20 minutes from 90. [caption id="attachment_89937" align="aligncenter" width="720"]

Adidas Futurecraft 4D Sneakers

Adidas Futurecraft 4D Sneakers Source: Adidas [/caption] 3D Printing Enables Customized Products Kolmar Korea, a Korean cosmetics manufacturer, announced in early March 2019 it successfully used 3D printing technology to create a cream that could be molded into different shapes. The company is using the technology to develop customized 3D-printed make-up products such as lipsticks and compact powder. Kolmar said that 3D printing enables the production of highly customized products and can print product designs with different ingredients without using molds. [caption id="attachment_89938" align="aligncenter" width="720"]

Kolmar Korea’s 3D-printed skin care cream

Kolmar Korea’s 3D-printed skin care cream Source: Kolmar Korea [/caption] Key Insights and Implications for Retailers 3D printing technology brings benefits to brands and retailers in various stages of the supply chain by speeding product design, shortening production lead time and making it possible to produce customized products at affordable cost. With further advances in 3D printing technology and increased accessibility and affordability, we believe 3D printing is a promising technology that offers many potential benefits to retailers from a supply chain perspective.