Nitheesh NH

Advances in robot technology have been driven by the constantly improving price-performance ratio of computing power, which in turn have driven increases in the power and capabilities of software, igniting the AI revolution. Seeing robots in warehouses or retail stores is no longer extraordinary, following Amazon’s acquisition of warehouse-robot maker Kiva Systems in 2012 and Walmart’s deployment of Bossa Nova shelf-scanning robots in 2017. As robotics technology continues its steady advance, we’re now seeing second-generation products and multiple robotics within the same category hit the market.

This report provides a market update and discusses robots used in warehouses and fulfillment centers; inside retail stores; and, to make coffee at trade shows and train stations.

Robotics Market Update

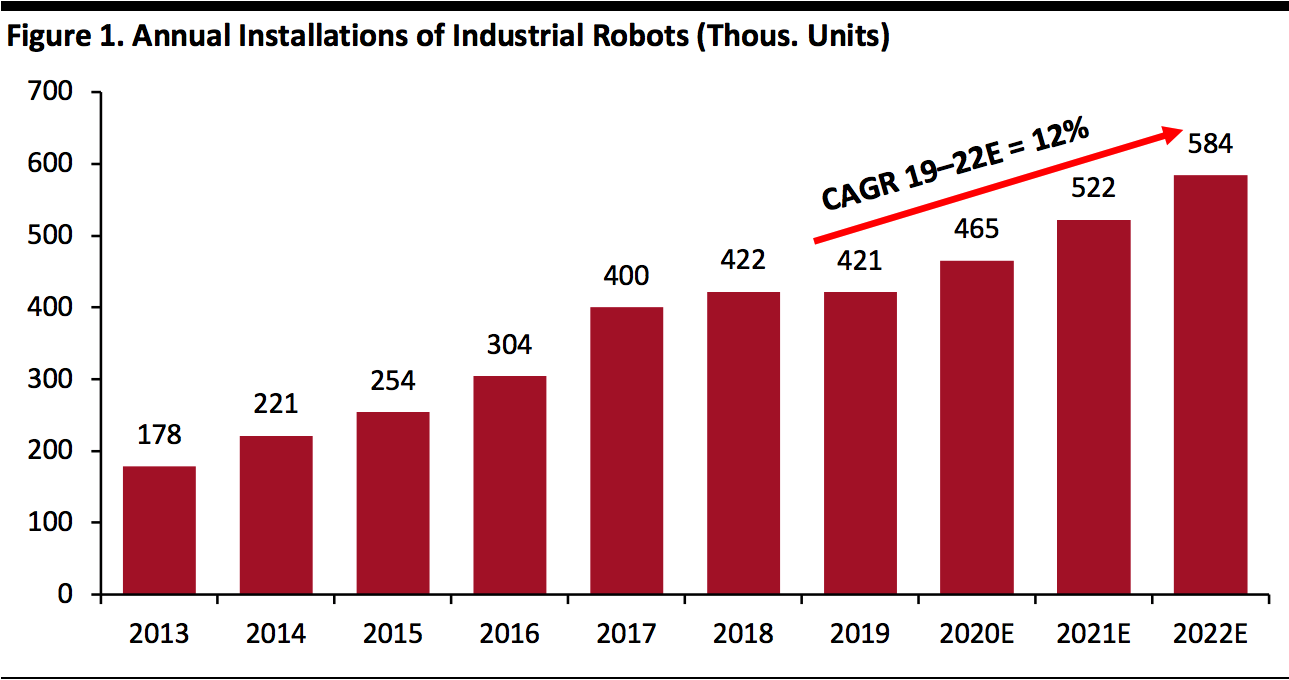

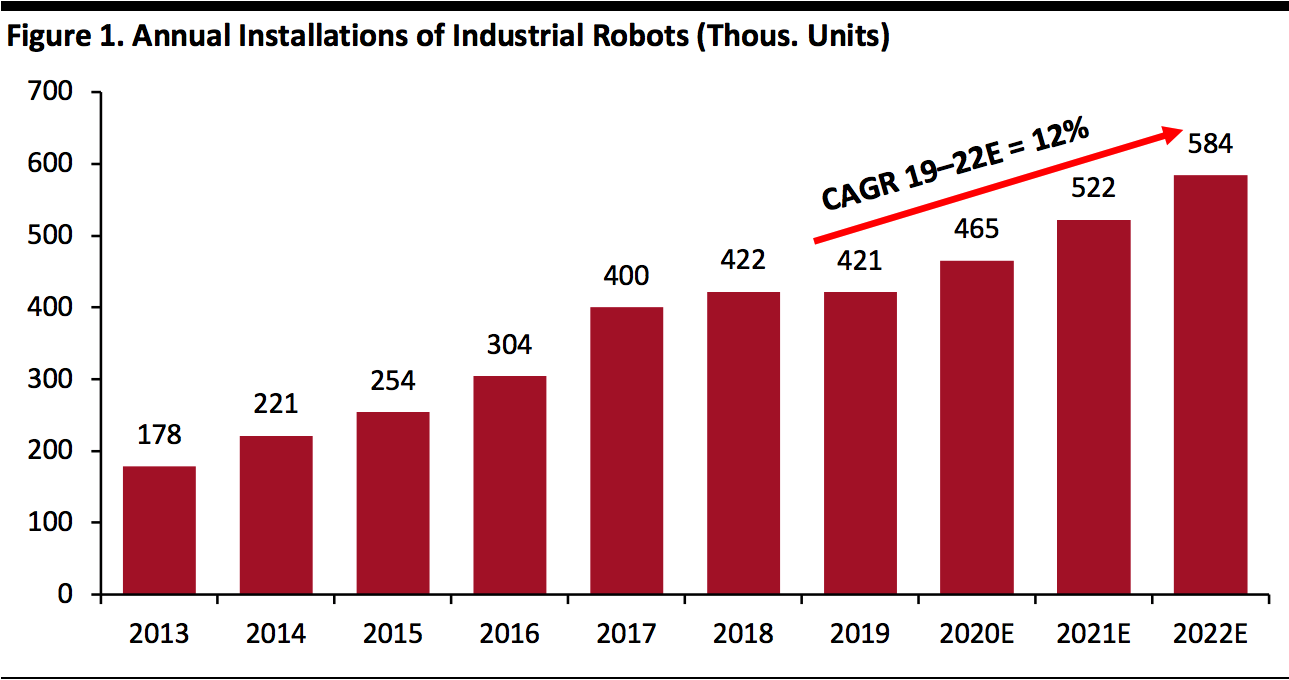

The IFR estimates 465,000 industrial robots will be installed in 2020, driving a 12% CAGR during 2019–2022. After five years of dynamic growth, including a 22% CAGR during 2013–2017, growth slowed in 2018 caused by difficulties in the automotive and electronics industries, then growth stalled further in 2019 due to the US-China trade conflict, but is expected to resume in 2020, depending on the outcome of the global coronavirus contagion.

According to the IFR, there were 2.4 million industrial robots operating in factories around the world as of January 2020, with the total value of these installations estimated at $16.5 billion.

[caption id="attachment_105119" align="aligncenter" width="700"] Source: World Robotics 2019[/caption]

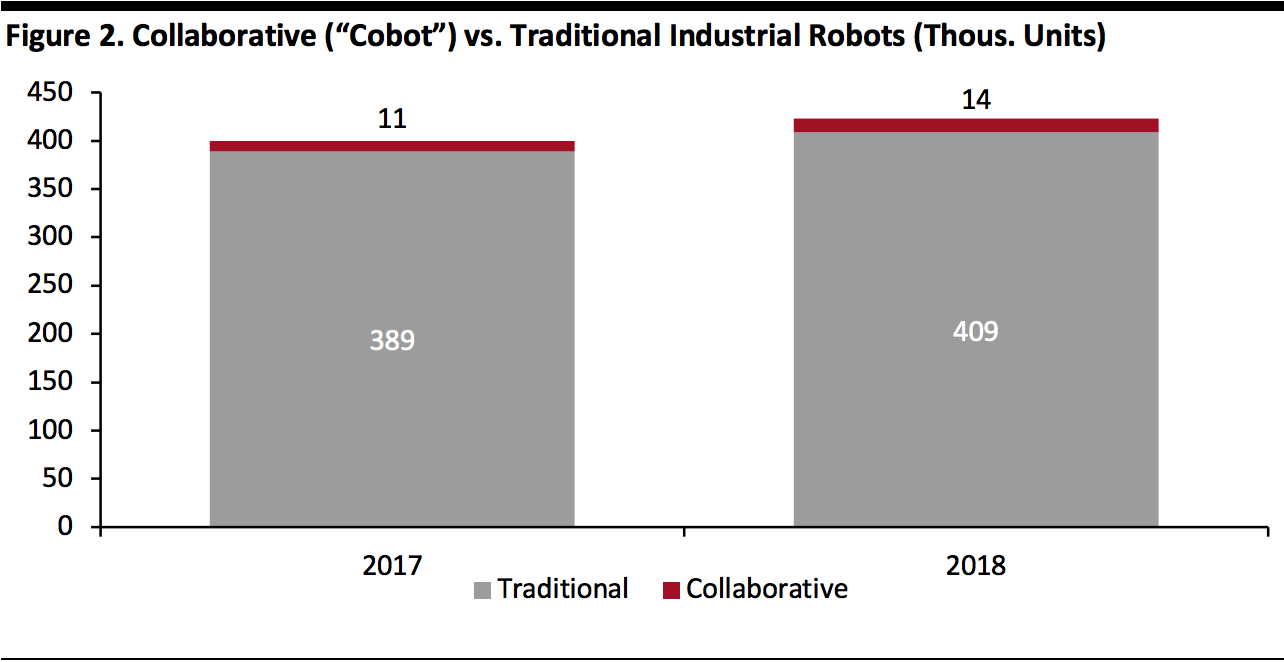

Robots Are Becoming Cobots

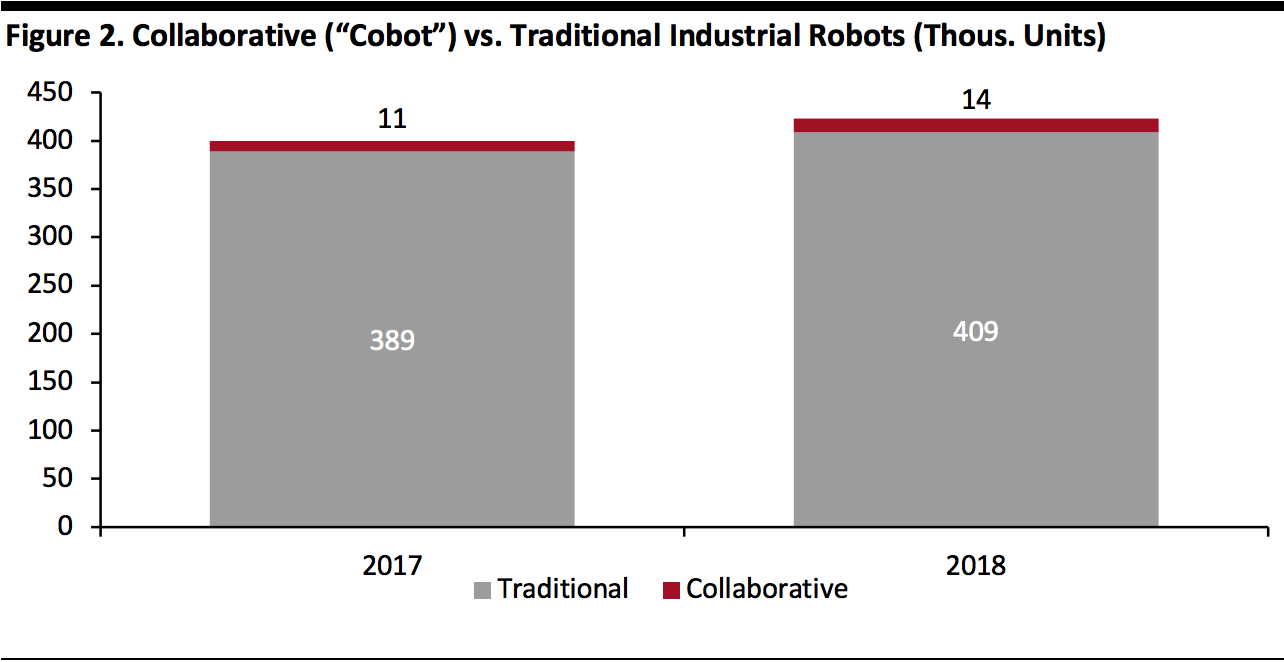

Collaborative industrial robots, now being referred to as “cobots,” are designed to work in concert with a human worker. For example, in a fulfillment center, workers load goods into a stack of bins that are transported by cobots to the workers who fill the boxes.

While cobots currently represent a small percentage of industrial robots (just 3.3% in 2018), use is growing.

[caption id="attachment_105120" align="aligncenter" width="700"]

Source: World Robotics 2019[/caption]

Robots Are Becoming Cobots

Collaborative industrial robots, now being referred to as “cobots,” are designed to work in concert with a human worker. For example, in a fulfillment center, workers load goods into a stack of bins that are transported by cobots to the workers who fill the boxes.

While cobots currently represent a small percentage of industrial robots (just 3.3% in 2018), use is growing.

[caption id="attachment_105120" align="aligncenter" width="700"] Source: World Robotics 2019[/caption]

Warehouse and Fulfillment Center Robots

In warehouses and fulfillment centers, human-robot teams work together picking, sorting, transporting and storing packages.

Amazon sent tremors through the industry with its acquisition of Kiva Systems in 2012, which it has rebranded as Amazon Robotics. It calls the robots that transport items across the warehouse “drive units,” and has built on Kiva technology with new designs. Two new models to sprout from the acquisition include the Xanthus, which, like the Kiva units, carries shelves, but its design is now more modular, and the Pegasus, which carries the packages that have been filled to leave the facility.

[caption id="attachment_105121" align="aligncenter" width="700"]

Source: World Robotics 2019[/caption]

Warehouse and Fulfillment Center Robots

In warehouses and fulfillment centers, human-robot teams work together picking, sorting, transporting and storing packages.

Amazon sent tremors through the industry with its acquisition of Kiva Systems in 2012, which it has rebranded as Amazon Robotics. It calls the robots that transport items across the warehouse “drive units,” and has built on Kiva technology with new designs. Two new models to sprout from the acquisition include the Xanthus, which, like the Kiva units, carries shelves, but its design is now more modular, and the Pegasus, which carries the packages that have been filled to leave the facility.

[caption id="attachment_105121" align="aligncenter" width="700"] Amazon Xanthus (left) and Pegasus (right)

Amazon Xanthus (left) and Pegasus (right)

Source: Company reports[/caption] Locus Robotics calls its robots LocusBots. They are designed to work side-by-side with humans and aim to minimize unproductive worker time spent walking, carrying items or pushing carts by instead autonomously traveling to where the workers are. The device automatically learns the most efficient travel routes to maximize pick efficiency and shares this information with other robots. [caption id="attachment_105122" align="aligncenter" width="320"] LocusBot

LocusBot

Source: Zebra Technologies[/caption] In-Store Robots In addition to robotic greeters and wayfinders, robots are now finding jobs inside the store taking inventory, notifying employees about dangerous spills and even mopping floors. Inventory Robots Bossa Nova gained notoriety when it was selected by Walmart for inventory scanning in 2017. At NRF 2020, Bossa Nova launched its second-generation shelf-scanning robot, offering several upgrades: Bossa Nova 2020 robot

Bossa Nova 2020 robot

Source: Bossa Nova[/caption] At NRF 2020, Zebra launched the SmartSight, a shelf-scanning robot for mass merchants, grocers and supermarkets available on a subscription basis. The robot can identify out-of-stock conditions, pricing inconsistencies and planogram issues on the shelf. It uses computer vision, machine learning, workflow automation and runs on Zebra’s EMA50 enterprise mobile automation system software. Zebra claims the SmartSight is smarter than the average shelf-scanning robot, in that in the event of an out-of-stock condition, it can communicate with store associates and the supply chain to replenish inventory. The company claims SmartSight increases store inventory availability to above 95%, which enables retailers to reassign an average of 65 labor hours per store per week to higher-value jobs. [caption id="attachment_105124" align="aligncenter" width="700"] SmartSight robot

SmartSight robot

Source: Zebra Technologies[/caption] Spill-Detecting Robots Badger Technologies offers a robot—named Marty—that offers similar functionality as the Bossa Nova and Zebra models, such as identifying issues such as out-of-stock merchandise, planogram compliance, price integrity, audit and compliance issues. Its platform offers one additional feature: hazard detection and mitigation. Its cameras identify potential hazards such as spills in the store. The device, though, is not able to identify spills with 100% accuracy—it sends images to a human-staffed control center for review before requesting a cleanup over its loudspeaker. Grocers testing the robot include Ahold Delhaize subsidiaries Giant, Martin’s and Stop & Shop. The robot even sports googly eyes to appear more friendly to humans. [caption id="attachment_105125" align="aligncenter" width="380"] Marty

Marty

Source: Badger Technologies[/caption] Floor-Mopping Robots Robots can now tackle tedious tasks such as scrubbing floors. San Diego-based Brain Corp has a deal to supply 360 floor-scrubbing robots powered by the company’s BrainOs software to Walmart by the end of January 2019. Walmart calls these robots the Auto-C, for “autonomous cleaner.” The robots free up associates to take care of other tasks. Avidbots also makes a floor-scrubbing robot called the Neo. [caption id="attachment_105126" align="aligncenter" width="700"] Auto-C floor scrubbing robot

Auto-C floor scrubbing robot

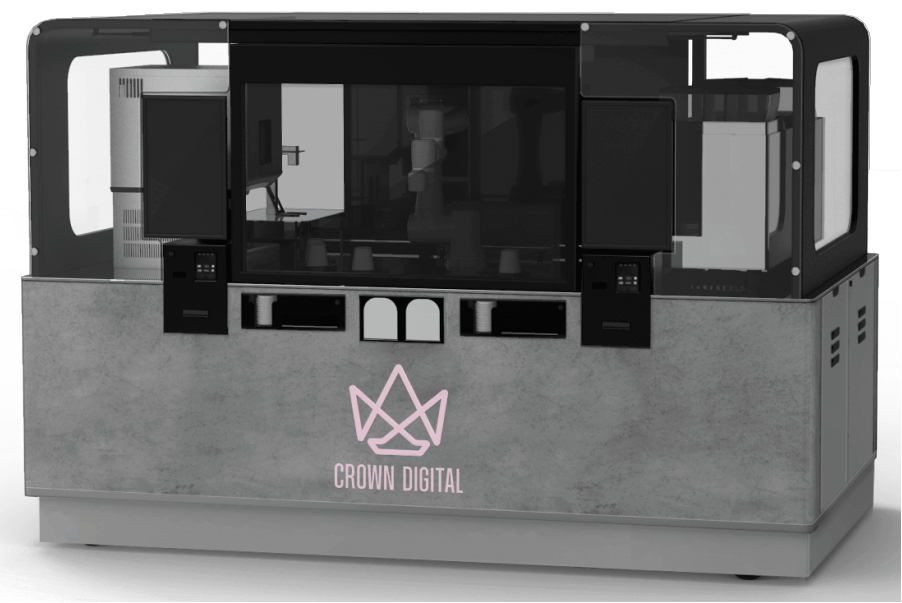

Source: Walmart[/caption] Food and Beverage-Preparation Robots At NRF 2020, Singapore-based coffee company Crown Digital demonstrated a portable, robotic four-espresso machine coffee station called Ella X, designed to alleviate the difficulty coffee shops have hiring, training and retaining workers in Singapore’s tight labor market. These robotic coffee stations are portable, contained in a small trailer (3 meters by 1.5 meters by 2.2 meters) and can be deployed in train stations, at trade shows, etc. Customers can order beverages via smartphone, including sending a message when they are on the way so the beverage is ready and hot. Crown Digital claims its station can make up 1,000 cups a day and serve tea and cocktails, in addition to coffee. [caption id="attachment_105127" align="aligncenter" width="480"] Ella X

Ella X

Source: Crown Digital[/caption] Please see other recent Coresight Research reports on robotics, including: How Robotics Is Transforming the Retail Value Chain Supply Chain Briefing: Robotics Brings Productivity to the Supply Chain and Speeds Last-Mile Delivery

Source: World Robotics 2019[/caption]

Robots Are Becoming Cobots

Collaborative industrial robots, now being referred to as “cobots,” are designed to work in concert with a human worker. For example, in a fulfillment center, workers load goods into a stack of bins that are transported by cobots to the workers who fill the boxes.

While cobots currently represent a small percentage of industrial robots (just 3.3% in 2018), use is growing.

[caption id="attachment_105120" align="aligncenter" width="700"]

Source: World Robotics 2019[/caption]

Robots Are Becoming Cobots

Collaborative industrial robots, now being referred to as “cobots,” are designed to work in concert with a human worker. For example, in a fulfillment center, workers load goods into a stack of bins that are transported by cobots to the workers who fill the boxes.

While cobots currently represent a small percentage of industrial robots (just 3.3% in 2018), use is growing.

[caption id="attachment_105120" align="aligncenter" width="700"] Source: World Robotics 2019[/caption]

Warehouse and Fulfillment Center Robots

In warehouses and fulfillment centers, human-robot teams work together picking, sorting, transporting and storing packages.

Amazon sent tremors through the industry with its acquisition of Kiva Systems in 2012, which it has rebranded as Amazon Robotics. It calls the robots that transport items across the warehouse “drive units,” and has built on Kiva technology with new designs. Two new models to sprout from the acquisition include the Xanthus, which, like the Kiva units, carries shelves, but its design is now more modular, and the Pegasus, which carries the packages that have been filled to leave the facility.

[caption id="attachment_105121" align="aligncenter" width="700"]

Source: World Robotics 2019[/caption]

Warehouse and Fulfillment Center Robots

In warehouses and fulfillment centers, human-robot teams work together picking, sorting, transporting and storing packages.

Amazon sent tremors through the industry with its acquisition of Kiva Systems in 2012, which it has rebranded as Amazon Robotics. It calls the robots that transport items across the warehouse “drive units,” and has built on Kiva technology with new designs. Two new models to sprout from the acquisition include the Xanthus, which, like the Kiva units, carries shelves, but its design is now more modular, and the Pegasus, which carries the packages that have been filled to leave the facility.

[caption id="attachment_105121" align="aligncenter" width="700"] Amazon Xanthus (left) and Pegasus (right)

Amazon Xanthus (left) and Pegasus (right)Source: Company reports[/caption] Locus Robotics calls its robots LocusBots. They are designed to work side-by-side with humans and aim to minimize unproductive worker time spent walking, carrying items or pushing carts by instead autonomously traveling to where the workers are. The device automatically learns the most efficient travel routes to maximize pick efficiency and shares this information with other robots. [caption id="attachment_105122" align="aligncenter" width="320"]

LocusBot

LocusBotSource: Zebra Technologies[/caption] In-Store Robots In addition to robotic greeters and wayfinders, robots are now finding jobs inside the store taking inventory, notifying employees about dangerous spills and even mopping floors. Inventory Robots Bossa Nova gained notoriety when it was selected by Walmart for inventory scanning in 2017. At NRF 2020, Bossa Nova launched its second-generation shelf-scanning robot, offering several upgrades:

- Slimmer for use in medium-sized and small-format stores.

- Expanded intelligence capabilities to scan fresh food, frozen food and apparel.

- A 2D and 3D camera system, including a custom-designed camera with multi-focus, high-speed and high-resolution optics.

- Image processing, starting in the camera itself and ending with AI in the cloud.

Bossa Nova 2020 robot

Bossa Nova 2020 robotSource: Bossa Nova[/caption] At NRF 2020, Zebra launched the SmartSight, a shelf-scanning robot for mass merchants, grocers and supermarkets available on a subscription basis. The robot can identify out-of-stock conditions, pricing inconsistencies and planogram issues on the shelf. It uses computer vision, machine learning, workflow automation and runs on Zebra’s EMA50 enterprise mobile automation system software. Zebra claims the SmartSight is smarter than the average shelf-scanning robot, in that in the event of an out-of-stock condition, it can communicate with store associates and the supply chain to replenish inventory. The company claims SmartSight increases store inventory availability to above 95%, which enables retailers to reassign an average of 65 labor hours per store per week to higher-value jobs. [caption id="attachment_105124" align="aligncenter" width="700"]

SmartSight robot

SmartSight robotSource: Zebra Technologies[/caption] Spill-Detecting Robots Badger Technologies offers a robot—named Marty—that offers similar functionality as the Bossa Nova and Zebra models, such as identifying issues such as out-of-stock merchandise, planogram compliance, price integrity, audit and compliance issues. Its platform offers one additional feature: hazard detection and mitigation. Its cameras identify potential hazards such as spills in the store. The device, though, is not able to identify spills with 100% accuracy—it sends images to a human-staffed control center for review before requesting a cleanup over its loudspeaker. Grocers testing the robot include Ahold Delhaize subsidiaries Giant, Martin’s and Stop & Shop. The robot even sports googly eyes to appear more friendly to humans. [caption id="attachment_105125" align="aligncenter" width="380"]

Marty

MartySource: Badger Technologies[/caption] Floor-Mopping Robots Robots can now tackle tedious tasks such as scrubbing floors. San Diego-based Brain Corp has a deal to supply 360 floor-scrubbing robots powered by the company’s BrainOs software to Walmart by the end of January 2019. Walmart calls these robots the Auto-C, for “autonomous cleaner.” The robots free up associates to take care of other tasks. Avidbots also makes a floor-scrubbing robot called the Neo. [caption id="attachment_105126" align="aligncenter" width="700"]

Auto-C floor scrubbing robot

Auto-C floor scrubbing robotSource: Walmart[/caption] Food and Beverage-Preparation Robots At NRF 2020, Singapore-based coffee company Crown Digital demonstrated a portable, robotic four-espresso machine coffee station called Ella X, designed to alleviate the difficulty coffee shops have hiring, training and retaining workers in Singapore’s tight labor market. These robotic coffee stations are portable, contained in a small trailer (3 meters by 1.5 meters by 2.2 meters) and can be deployed in train stations, at trade shows, etc. Customers can order beverages via smartphone, including sending a message when they are on the way so the beverage is ready and hot. Crown Digital claims its station can make up 1,000 cups a day and serve tea and cocktails, in addition to coffee. [caption id="attachment_105127" align="aligncenter" width="480"]

Ella X

Ella XSource: Crown Digital[/caption] Please see other recent Coresight Research reports on robotics, including: How Robotics Is Transforming the Retail Value Chain Supply Chain Briefing: Robotics Brings Productivity to the Supply Chain and Speeds Last-Mile Delivery