DIpil Das

Although RFID technology was developed more than 70 years ago, it is now being used in expanded retail applications such as inventory tracking—helping retailers to offer BOPIS and ship-from-store services. The technology uses electromagnetic fields to identify and track electronic chips, which are typically attached to a product via a tag. Unlike barcodes, RFID does not require the tag to be within the line of sight of the scanner. This technology appeals to retailers due to the decreasing cost of RFID tags and the added benefits that new applications are providing, which we discuss in this report.

RFID in Retail: An Overview

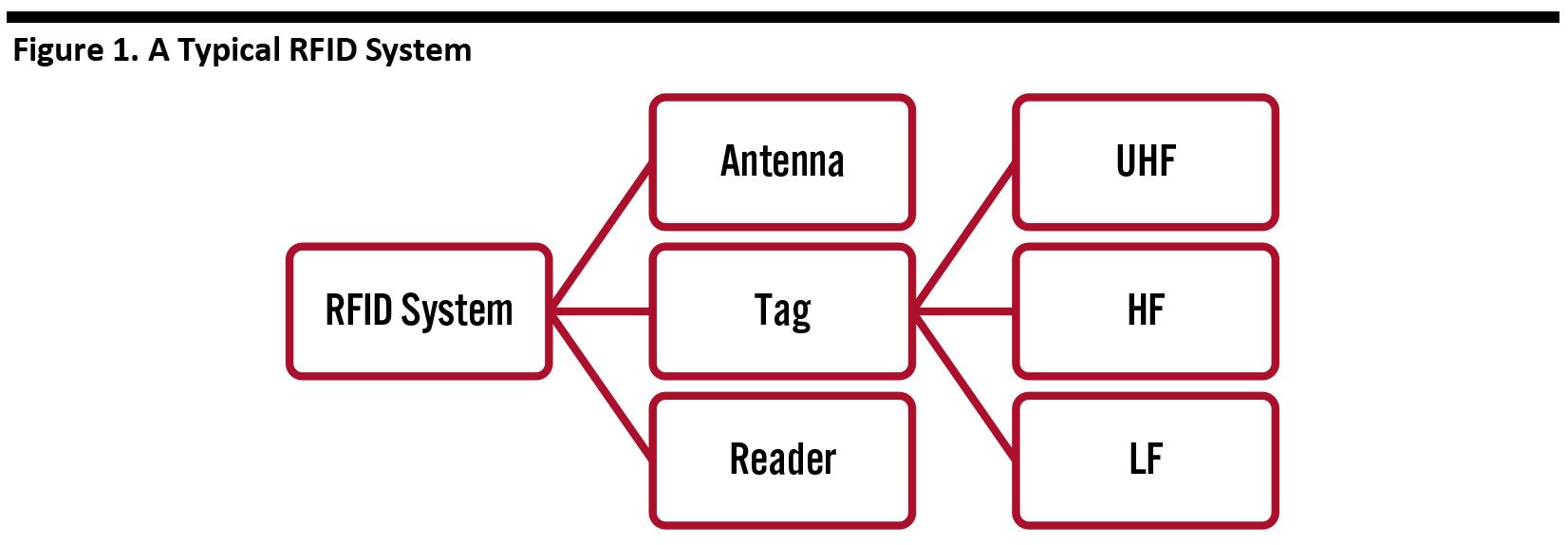

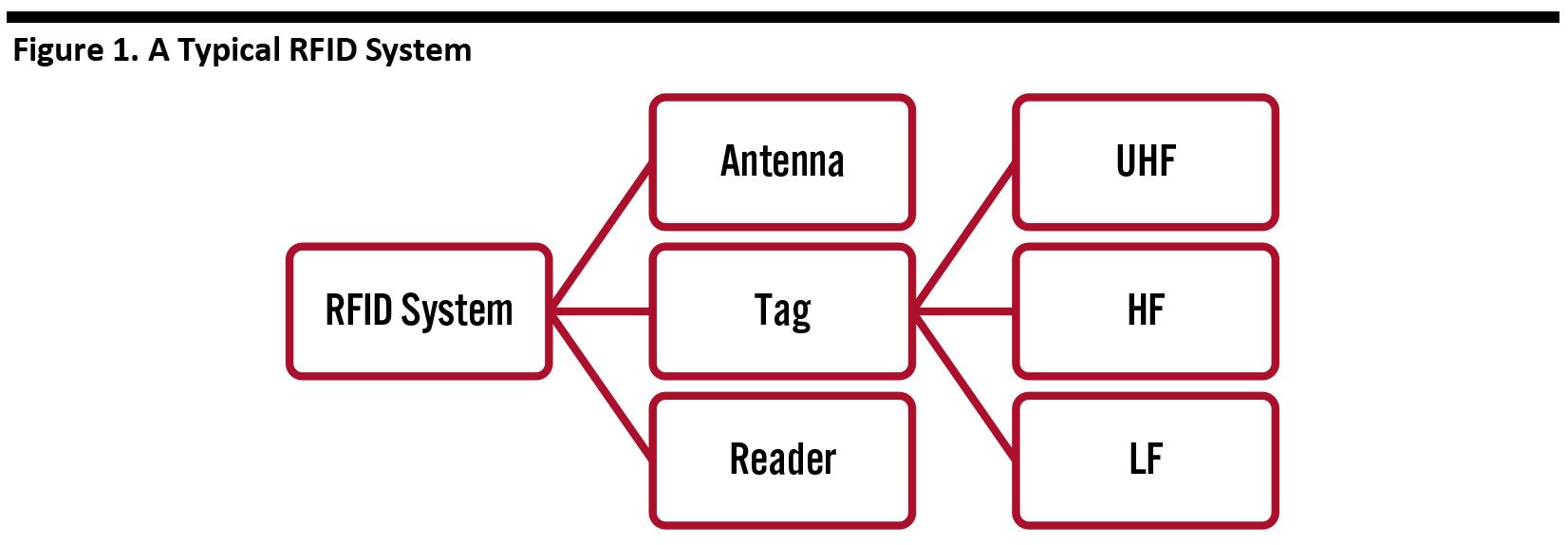

A typical RFID system comprises a tag, an antenna and a reader. The RFID market—which includes systems, software and services—is estimated by research firm IDTechEx to have been worth $11.6 billion in 2019, and this is expected to grow at a 6% CAGR during 2019–2024.

RFID encompasses different frequencies—UHF (ultra-high frequency), HF (high frequency) and LF (low frequency)—and standards, including NFC and RAIN (Radio Frequency Identification). The latter is wireless technology that connects tags to the Internet, enabling retailers to identify and locate each item. The total number of RAIN RFID tags sold is expected to increase from 15.0 billion in 2019 to 41.2 billion in 2024, according to IDTechEx—representing a 22.5% CAGR.

[caption id="attachment_109619" align="aligncenter" width="700"] Source: Coresight Research[/caption]

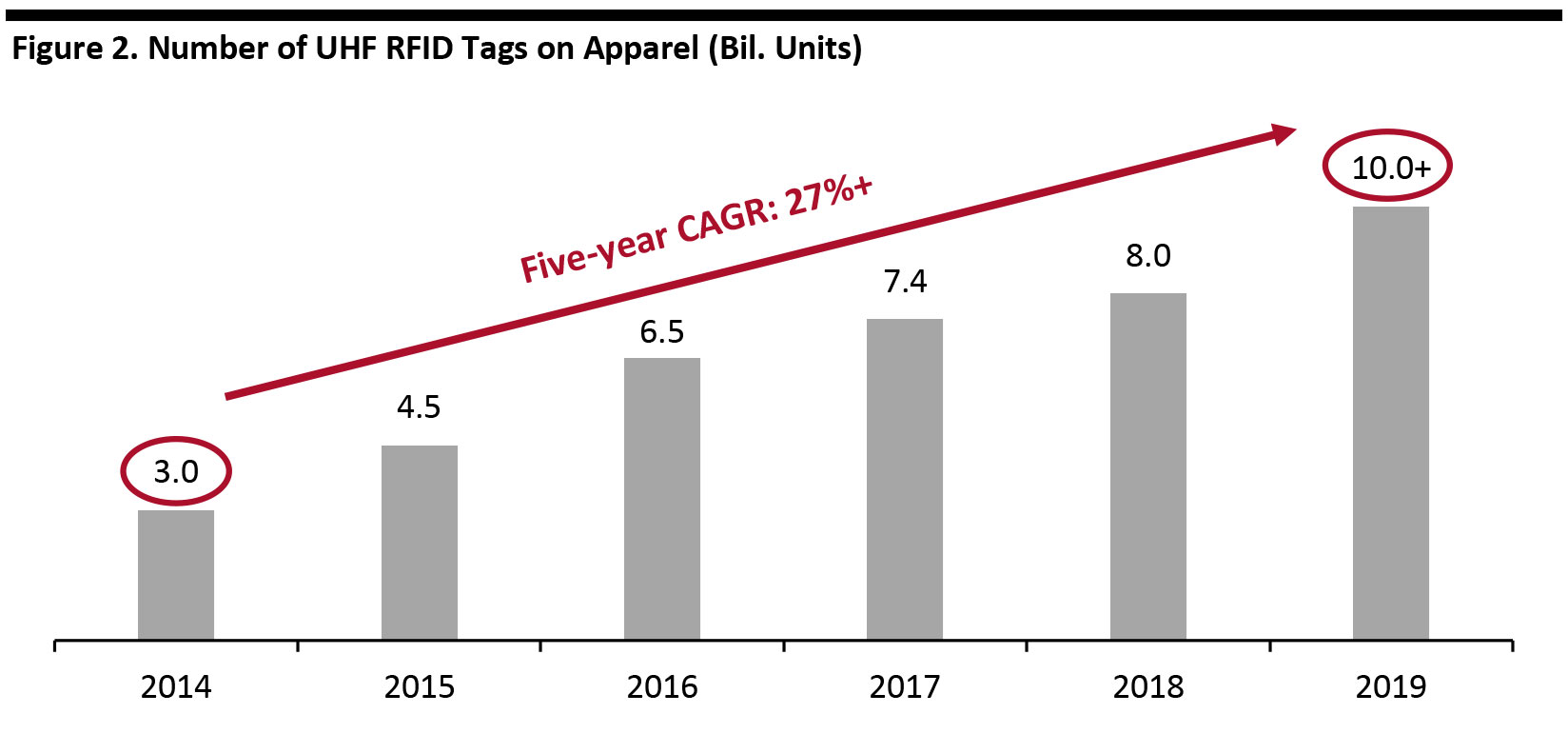

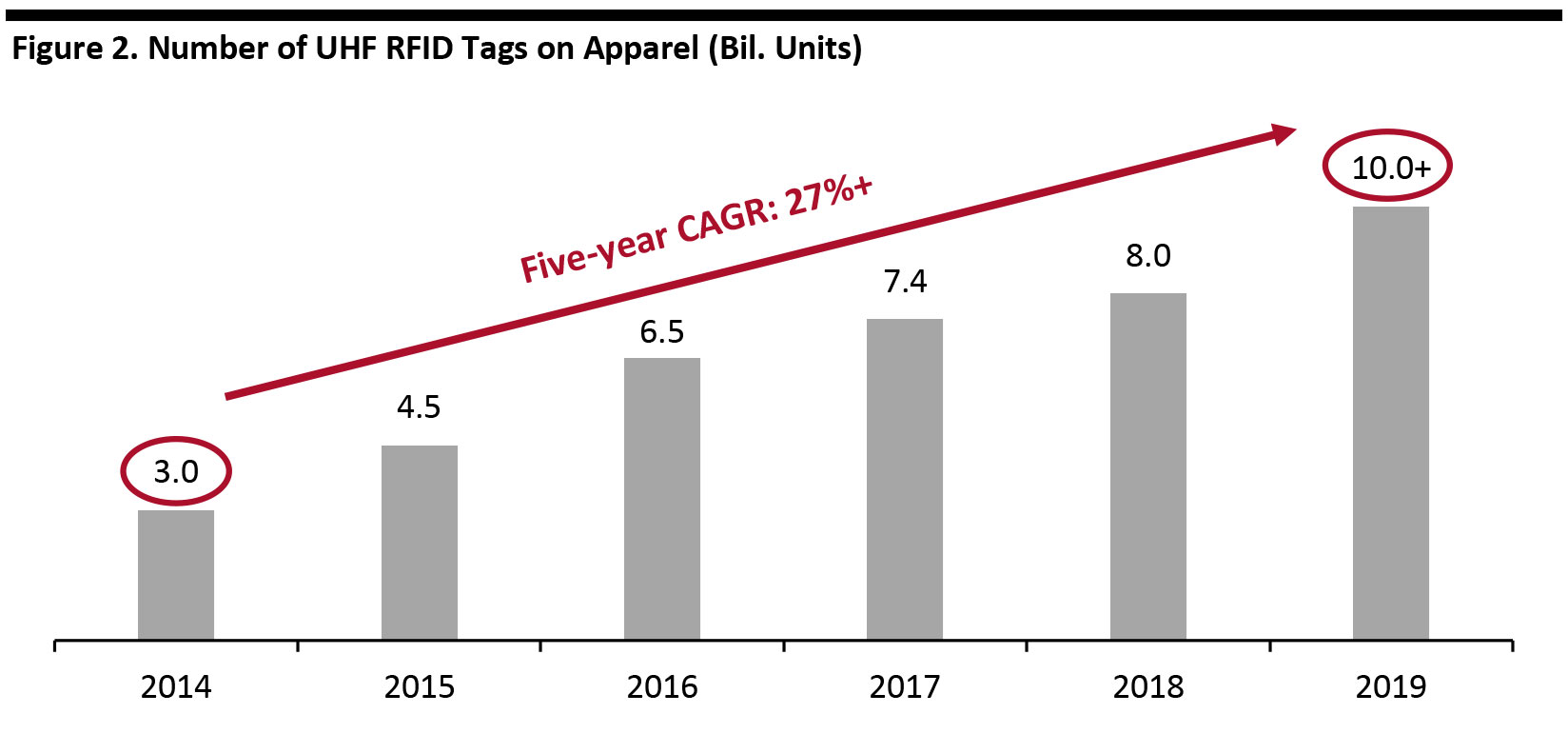

Many retailers already use RFID tags, particularly on apparel products. IDTechEx estimates that the number of UHF RFID tags in use on apparel products totaled more than 10 billion in 2019.

[caption id="attachment_109620" align="aligncenter" width="700"]

Source: Coresight Research[/caption]

Many retailers already use RFID tags, particularly on apparel products. IDTechEx estimates that the number of UHF RFID tags in use on apparel products totaled more than 10 billion in 2019.

[caption id="attachment_109620" align="aligncenter" width="700"] Source: IDTechEx[/caption]

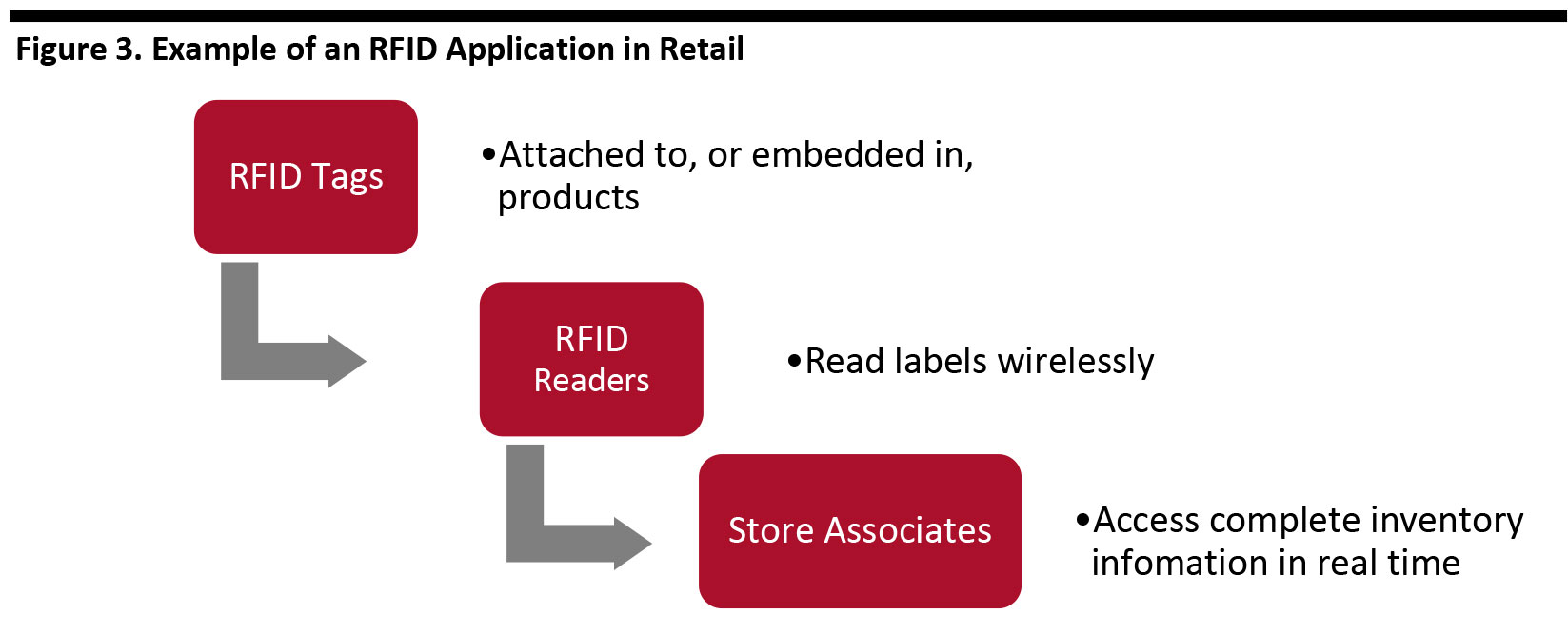

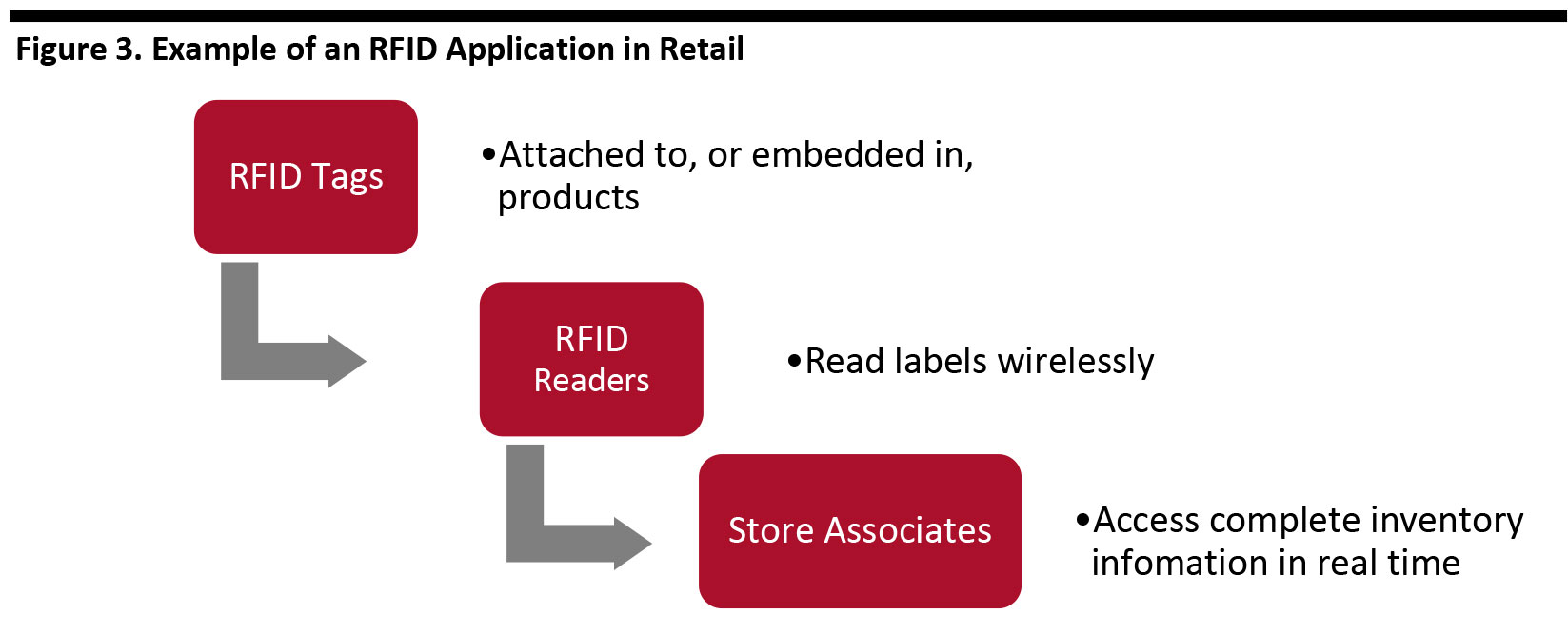

RFID item-level tracking capabilities help retailers to increase the efficiency of inventory management through real-time insights. Furthermore, by combining RFID tags with Internet of Things (IoT) technology, retailers can use the data collected from RFID tags for loss prevention and other applications. Signals received from RFID tags can be stored and managed in the cloud, allowing RFID-based data to be easily accessed and analyzed.

[caption id="attachment_109621" align="aligncenter" width="700"]

Source: IDTechEx[/caption]

RFID item-level tracking capabilities help retailers to increase the efficiency of inventory management through real-time insights. Furthermore, by combining RFID tags with Internet of Things (IoT) technology, retailers can use the data collected from RFID tags for loss prevention and other applications. Signals received from RFID tags can be stored and managed in the cloud, allowing RFID-based data to be easily accessed and analyzed.

[caption id="attachment_109621" align="aligncenter" width="700"] Source: Coresight Research[/caption]

Below, we discuss several innovative RFID applications and technology breakthroughs from leading industry providers.

Microwave-Safe RFID Tags

Avery Dennison is a developer of the first UHF RIFD tag solution that is safe for use in microwave ovens—the culmination of 10 years of research. (Avery Dennison co-announced the product with another RFID solution provider Impinj.) This microwave-safe tag, designed specifically for the food industry, allows item-level tagging and data accuracy. The tag is suitable for chilled or frozen packaged foods and is able to withstand up to five minutes in a 950-watt microwave, which is long enough for most microwaveable products.

For consumers, this is particularly useful for prepared meals, as they can heat the food directly in the original packaging. For retailers, this innovation means that the use of RFID tags can be expanded to more product categories.

[caption id="attachment_109622" align="aligncenter" width="700"]

Source: Coresight Research[/caption]

Below, we discuss several innovative RFID applications and technology breakthroughs from leading industry providers.

Microwave-Safe RFID Tags

Avery Dennison is a developer of the first UHF RIFD tag solution that is safe for use in microwave ovens—the culmination of 10 years of research. (Avery Dennison co-announced the product with another RFID solution provider Impinj.) This microwave-safe tag, designed specifically for the food industry, allows item-level tagging and data accuracy. The tag is suitable for chilled or frozen packaged foods and is able to withstand up to five minutes in a 950-watt microwave, which is long enough for most microwaveable products.

For consumers, this is particularly useful for prepared meals, as they can heat the food directly in the original packaging. For retailers, this innovation means that the use of RFID tags can be expanded to more product categories.

[caption id="attachment_109622" align="aligncenter" width="700"] Avery Dennison microwave-safe UHF RFID tag

Avery Dennison microwave-safe UHF RFID tag

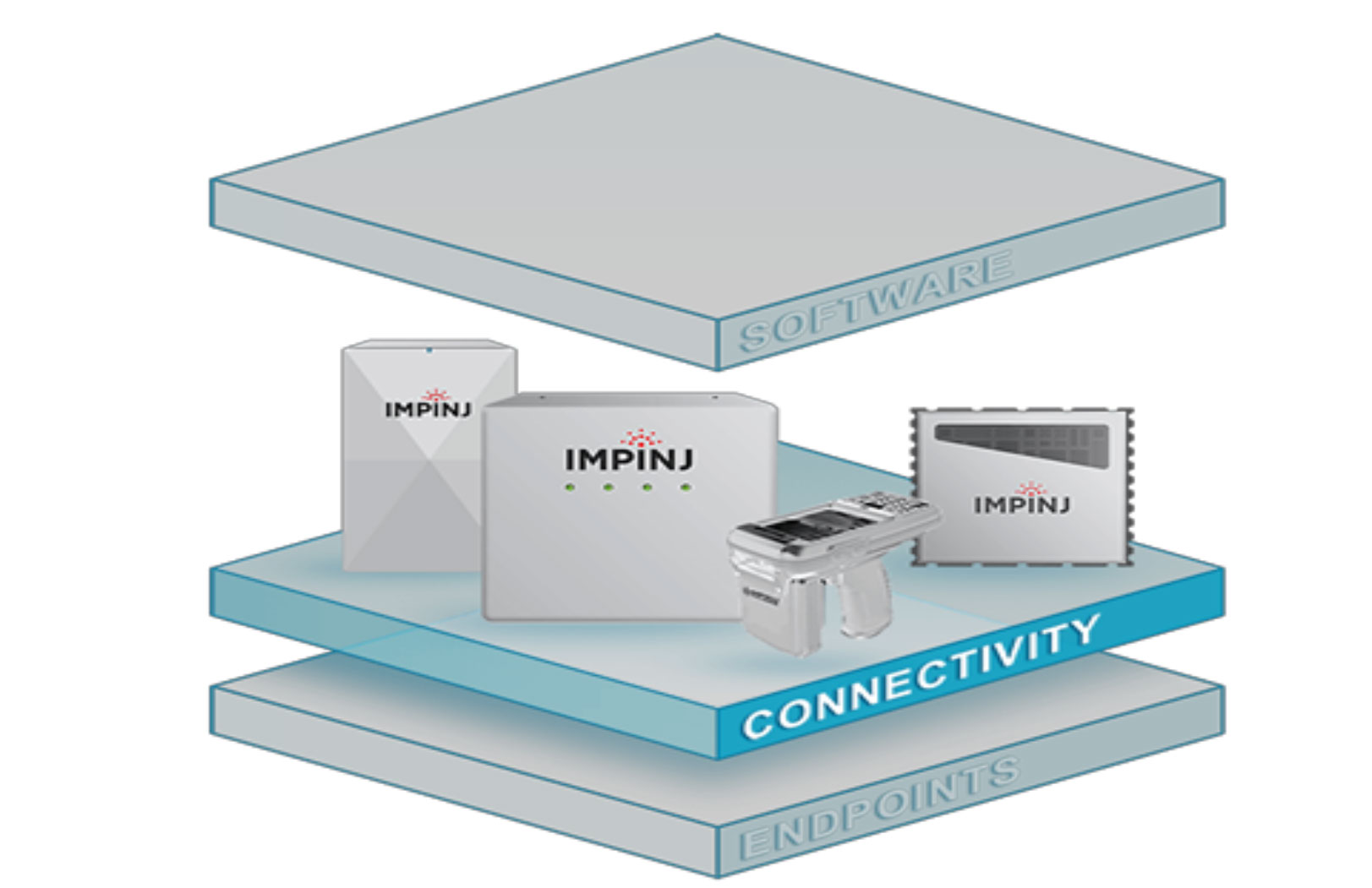

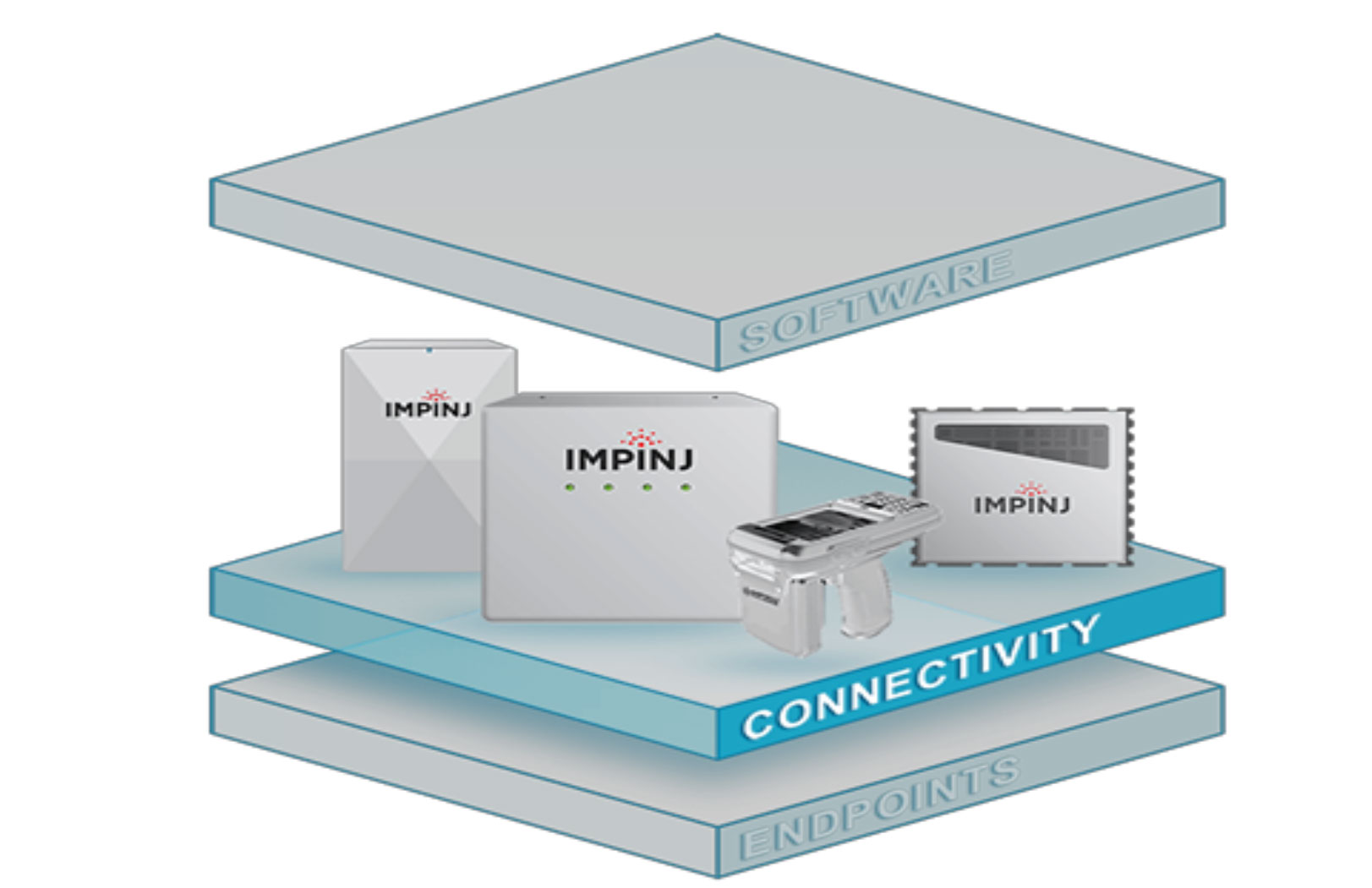

Source: Avery Dennison/YouTube [/caption] Separately, in March 2020, Avery Dennison closed the acquisition of Smartrac’s RFID Transponder business, which was announced in November 2019. Smartrac provides both ready-made and customized RFID products and IoT solutions for applications including animal identification, brand protection, customer experience, automobiles/tires tagging and supply chain management. The transaction will complement Avery Dennison’s Intelligent Labels platform, bring production in house and expanding the company’s current product portfolio, as well as providing benefits to research and development, manufacturing and sales capacity. Recent Advances Bring Smaller Chips, Protected Mode and Area Scanning Impinj announced the launch of two new RFID chips in December 2019—the M730 and M750 integrated circuits (ICs) of the M700 endpoint IC family. These new ICs are significantly smaller in size than previous models available, enabling the development of small and universal standard RAIN RFID tags that can thus be attached to a larger selection of items. These chips also feature a “protected mode,” which means that no other reader can see the tag and a PIN is required to make it visible again. Retailers can use this mode to hide a purchased item from loss-prevention systems; if the product is returned, the tag can simply be turned on again using the PIN. This technology enhances loss prevention, frictionless self-checkout and seamless returns. In February 2020, Impinj introduced a new enterprise-grade R700 RAIN RFID reader. The reader is designed to simplify solution deployment—allowing developers to build customized solutions—and it supports common data-transfer technologies. In addition, the reader has the ability to recognize moving items, so can track packages moving from a delivery truck to the store. Benefits therefore include shipment verification, inventory management and asset tracking, facilitating control and visibility at every step in the supply chain. [caption id="attachment_109623" align="aligncenter" width="700"] The Impinj platform

The Impinj platform

Source: Impinj [/caption] New Generations of Intelligent Software Enhance Inventory and Provide Predictive Analytics Johnson Controls’ Sensormatic Solutions division demonstrated its TrueVue Inventory Intelligence Software as a Service (SaaS), built on the Google Cloud Platform at EuroShop in February 2020. The SaaS solution offers retailers accurate inventory availability in real time, enabling unified commerce fulfillment and delivering actionable insights and predictive analytics. According to Johnson Controls, TrueVue was built as an extensible API-first design to simplify the integration process and offer high accuracy for inventory and cycle counts. Through RFID cycle counting, interactive restocking and inventory analytics, retailers can gain better knowledge about merchandise availability on the sales floor and in the stock room. They can also quickly identify out-of-stock items, reserve inventories and process returns. The solution facilitates BOPIS services through its automatic order notification, picking and fulfillment features. In addition, TrueVue’s “Item Label and Recipe” configuration options allow retailers to specify precise inventory outcomes. Tracking Inventory, Profitability and Professional Athletes The SmartLens for Retail, developed by Zebra Technologies, provides retailers with the ability to conduct analysis and take real-time actions to increase sales, enable omnichannel operations and reduce shrink and operational costs. The foundation of this solution is a family of RFID readers that automatically senses and records the location and movement of merchandise and assets throughout the retail store. Its data analytics engine aggregates and correlates the data collected by the RFID sensors into meaningful business information, which provides inventory visibility for real-time asset intelligence. The company also offers its ATR7000 reader, a ceiling-mounted passive RFID reader that uses multiple RFID radios to cover an area and provide real-time product visibility. The reader works with any passive tag, including Zebra’s ZBR4000 Inlay, which has high sensitivity and low orientation bias, thereby avoiding orientation issues. With its acquisition of Profitect in June 2019, Zebra added innovative software analytics to its portfolio and has since rebranded the solution as Zebra Prescriptive Analytics (ZPA). Its turnkey SaaS solution analyzes a retailer’s or CPG company’s data (barcode, RFID or from other sources), identifies opportunities and prescribes actions for the right individual to take at the right time—with the aim of improving inventory management and reducing shrink. Zebra has also outfitted professional US NFL football players with second-generation ultrawideband active RFID tags for real-time athlete tracking. Using this technology, athletes can measure their performance, enhancing coaching, training and even the fan experience. The offering leverages Zebra’s MotionWorks platform, which includes solutions for warehouse operations, manufacturing workflows and asset tracking. Japan Encourages the Use of Electronic Tags in Convenience Stores In Japan, convenience stores are everywhere and tend to be open 24/7. Facing a shortage of labor due to the long-term declining birth rate, the Japanese government is looking for technology solutions to address labor market challenges. In 2017, Japan’s Ministry of Economy, Trade and Industry (METI) launched a project to encourage retailers to use electronic tags on all merchandise, from gum to lunch boxes. The goal is to eventually transform stores to be entirely unstaffed as well as to reduce food waste. With RFID tags, retailers can track products’ expiration dates more efficiently and market products better with dynamic pricing. Shoppers can also scan the tag for more information on the product. After a successful pilot in select convenience stores, METI plans to achieve a full rollout of its initiative across all stores in Japan by 2025. 7Eleven, FamilyMart, Lawson, NewDays, Ministop and JR East Retail Net have agreed to introduce RFID tags on all their products within the next five years: The total number of items sold in the stores of these five major chains is estimated to be 100 billion annually, according to METI. Another example of the adoption of RFID tags is Italian retailer Esselunga, which opened its first experimental grocery store in Milan in December 2019, selling about 2,500 products that all have RFID tags.

Source: Coresight Research[/caption]

Many retailers already use RFID tags, particularly on apparel products. IDTechEx estimates that the number of UHF RFID tags in use on apparel products totaled more than 10 billion in 2019.

[caption id="attachment_109620" align="aligncenter" width="700"]

Source: Coresight Research[/caption]

Many retailers already use RFID tags, particularly on apparel products. IDTechEx estimates that the number of UHF RFID tags in use on apparel products totaled more than 10 billion in 2019.

[caption id="attachment_109620" align="aligncenter" width="700"] Source: IDTechEx[/caption]

RFID item-level tracking capabilities help retailers to increase the efficiency of inventory management through real-time insights. Furthermore, by combining RFID tags with Internet of Things (IoT) technology, retailers can use the data collected from RFID tags for loss prevention and other applications. Signals received from RFID tags can be stored and managed in the cloud, allowing RFID-based data to be easily accessed and analyzed.

[caption id="attachment_109621" align="aligncenter" width="700"]

Source: IDTechEx[/caption]

RFID item-level tracking capabilities help retailers to increase the efficiency of inventory management through real-time insights. Furthermore, by combining RFID tags with Internet of Things (IoT) technology, retailers can use the data collected from RFID tags for loss prevention and other applications. Signals received from RFID tags can be stored and managed in the cloud, allowing RFID-based data to be easily accessed and analyzed.

[caption id="attachment_109621" align="aligncenter" width="700"] Source: Coresight Research[/caption]

Below, we discuss several innovative RFID applications and technology breakthroughs from leading industry providers.

Microwave-Safe RFID Tags

Avery Dennison is a developer of the first UHF RIFD tag solution that is safe for use in microwave ovens—the culmination of 10 years of research. (Avery Dennison co-announced the product with another RFID solution provider Impinj.) This microwave-safe tag, designed specifically for the food industry, allows item-level tagging and data accuracy. The tag is suitable for chilled or frozen packaged foods and is able to withstand up to five minutes in a 950-watt microwave, which is long enough for most microwaveable products.

For consumers, this is particularly useful for prepared meals, as they can heat the food directly in the original packaging. For retailers, this innovation means that the use of RFID tags can be expanded to more product categories.

[caption id="attachment_109622" align="aligncenter" width="700"]

Source: Coresight Research[/caption]

Below, we discuss several innovative RFID applications and technology breakthroughs from leading industry providers.

Microwave-Safe RFID Tags

Avery Dennison is a developer of the first UHF RIFD tag solution that is safe for use in microwave ovens—the culmination of 10 years of research. (Avery Dennison co-announced the product with another RFID solution provider Impinj.) This microwave-safe tag, designed specifically for the food industry, allows item-level tagging and data accuracy. The tag is suitable for chilled or frozen packaged foods and is able to withstand up to five minutes in a 950-watt microwave, which is long enough for most microwaveable products.

For consumers, this is particularly useful for prepared meals, as they can heat the food directly in the original packaging. For retailers, this innovation means that the use of RFID tags can be expanded to more product categories.

[caption id="attachment_109622" align="aligncenter" width="700"] Avery Dennison microwave-safe UHF RFID tag

Avery Dennison microwave-safe UHF RFID tag Source: Avery Dennison/YouTube [/caption] Separately, in March 2020, Avery Dennison closed the acquisition of Smartrac’s RFID Transponder business, which was announced in November 2019. Smartrac provides both ready-made and customized RFID products and IoT solutions for applications including animal identification, brand protection, customer experience, automobiles/tires tagging and supply chain management. The transaction will complement Avery Dennison’s Intelligent Labels platform, bring production in house and expanding the company’s current product portfolio, as well as providing benefits to research and development, manufacturing and sales capacity. Recent Advances Bring Smaller Chips, Protected Mode and Area Scanning Impinj announced the launch of two new RFID chips in December 2019—the M730 and M750 integrated circuits (ICs) of the M700 endpoint IC family. These new ICs are significantly smaller in size than previous models available, enabling the development of small and universal standard RAIN RFID tags that can thus be attached to a larger selection of items. These chips also feature a “protected mode,” which means that no other reader can see the tag and a PIN is required to make it visible again. Retailers can use this mode to hide a purchased item from loss-prevention systems; if the product is returned, the tag can simply be turned on again using the PIN. This technology enhances loss prevention, frictionless self-checkout and seamless returns. In February 2020, Impinj introduced a new enterprise-grade R700 RAIN RFID reader. The reader is designed to simplify solution deployment—allowing developers to build customized solutions—and it supports common data-transfer technologies. In addition, the reader has the ability to recognize moving items, so can track packages moving from a delivery truck to the store. Benefits therefore include shipment verification, inventory management and asset tracking, facilitating control and visibility at every step in the supply chain. [caption id="attachment_109623" align="aligncenter" width="700"]

The Impinj platform

The Impinj platform Source: Impinj [/caption] New Generations of Intelligent Software Enhance Inventory and Provide Predictive Analytics Johnson Controls’ Sensormatic Solutions division demonstrated its TrueVue Inventory Intelligence Software as a Service (SaaS), built on the Google Cloud Platform at EuroShop in February 2020. The SaaS solution offers retailers accurate inventory availability in real time, enabling unified commerce fulfillment and delivering actionable insights and predictive analytics. According to Johnson Controls, TrueVue was built as an extensible API-first design to simplify the integration process and offer high accuracy for inventory and cycle counts. Through RFID cycle counting, interactive restocking and inventory analytics, retailers can gain better knowledge about merchandise availability on the sales floor and in the stock room. They can also quickly identify out-of-stock items, reserve inventories and process returns. The solution facilitates BOPIS services through its automatic order notification, picking and fulfillment features. In addition, TrueVue’s “Item Label and Recipe” configuration options allow retailers to specify precise inventory outcomes. Tracking Inventory, Profitability and Professional Athletes The SmartLens for Retail, developed by Zebra Technologies, provides retailers with the ability to conduct analysis and take real-time actions to increase sales, enable omnichannel operations and reduce shrink and operational costs. The foundation of this solution is a family of RFID readers that automatically senses and records the location and movement of merchandise and assets throughout the retail store. Its data analytics engine aggregates and correlates the data collected by the RFID sensors into meaningful business information, which provides inventory visibility for real-time asset intelligence. The company also offers its ATR7000 reader, a ceiling-mounted passive RFID reader that uses multiple RFID radios to cover an area and provide real-time product visibility. The reader works with any passive tag, including Zebra’s ZBR4000 Inlay, which has high sensitivity and low orientation bias, thereby avoiding orientation issues. With its acquisition of Profitect in June 2019, Zebra added innovative software analytics to its portfolio and has since rebranded the solution as Zebra Prescriptive Analytics (ZPA). Its turnkey SaaS solution analyzes a retailer’s or CPG company’s data (barcode, RFID or from other sources), identifies opportunities and prescribes actions for the right individual to take at the right time—with the aim of improving inventory management and reducing shrink. Zebra has also outfitted professional US NFL football players with second-generation ultrawideband active RFID tags for real-time athlete tracking. Using this technology, athletes can measure their performance, enhancing coaching, training and even the fan experience. The offering leverages Zebra’s MotionWorks platform, which includes solutions for warehouse operations, manufacturing workflows and asset tracking. Japan Encourages the Use of Electronic Tags in Convenience Stores In Japan, convenience stores are everywhere and tend to be open 24/7. Facing a shortage of labor due to the long-term declining birth rate, the Japanese government is looking for technology solutions to address labor market challenges. In 2017, Japan’s Ministry of Economy, Trade and Industry (METI) launched a project to encourage retailers to use electronic tags on all merchandise, from gum to lunch boxes. The goal is to eventually transform stores to be entirely unstaffed as well as to reduce food waste. With RFID tags, retailers can track products’ expiration dates more efficiently and market products better with dynamic pricing. Shoppers can also scan the tag for more information on the product. After a successful pilot in select convenience stores, METI plans to achieve a full rollout of its initiative across all stores in Japan by 2025. 7Eleven, FamilyMart, Lawson, NewDays, Ministop and JR East Retail Net have agreed to introduce RFID tags on all their products within the next five years: The total number of items sold in the stores of these five major chains is estimated to be 100 billion annually, according to METI. Another example of the adoption of RFID tags is Italian retailer Esselunga, which opened its first experimental grocery store in Milan in December 2019, selling about 2,500 products that all have RFID tags.