albert Chan

Introduction

What’s the Story?

The warehouse is no longer a dusty shed where goods are stacked in a remote location until collected by workers with forklifts. Rather, warehouses form the central nervous system of the supply chain, connecting supply and demand. Warehouses represent the intersection of inventory, labor, automation and transportation, driven by advanced technology—including AI/ML (artificial intelligence/machine learning)—that keeps goods moving to get to consumers at the precisely needed moment.

In addition to managing the optimal location of goods within the warehouse, warehouse management platforms also interconnect with the major operational platforms of a retailer, including finance, inventory, logistics and labor.

We explore the position of the warehouse in the modern, technology-powered supply chain and the functional areas of warehouse management platforms. We also discuss enabling technologies and leading warehouse management software solution providers.

Why It Matters

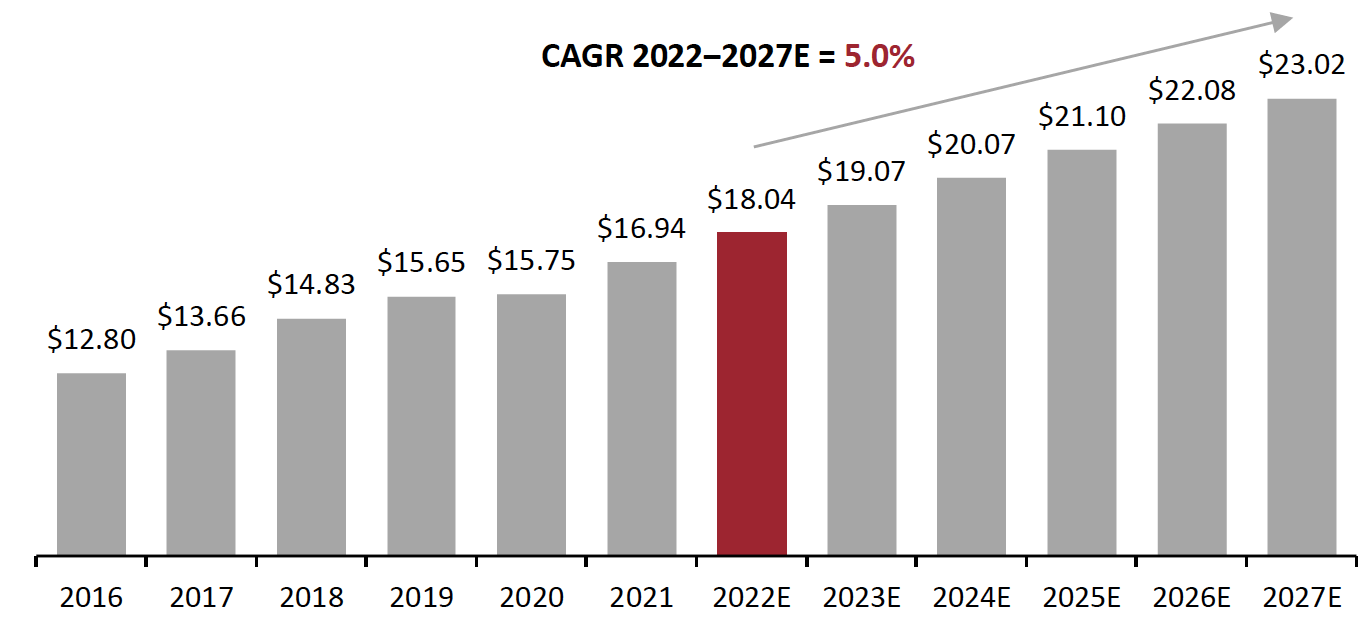

The warehouse management software segment represents a multibillion-dollar segment within the $18 billion overall supply chain management software market, which is set to grow at a 5.0% CAGR through 2027, according to Statista (see Figure 1).

Figure 1. Global Supply Chain Management Software Market (USD Bil.)

[caption id="attachment_150922" align="aligncenter" width="550"] Source: Company reports/national statistics offices/Statista[/caption]

Source: Company reports/national statistics offices/Statista[/caption]

What happens in the warehouse has direct implications for profitability, as it relates to inventory management (and therefore working capital), as well as delivery speed, which is essential as the retail industry continues to move to ever-shorter delivery times, spurred onward by Amazon and instant-needs retailers. Delivery speed has an enormous influence on customer satisfaction.

Warehouse Management Software: Coresight Research Analysis

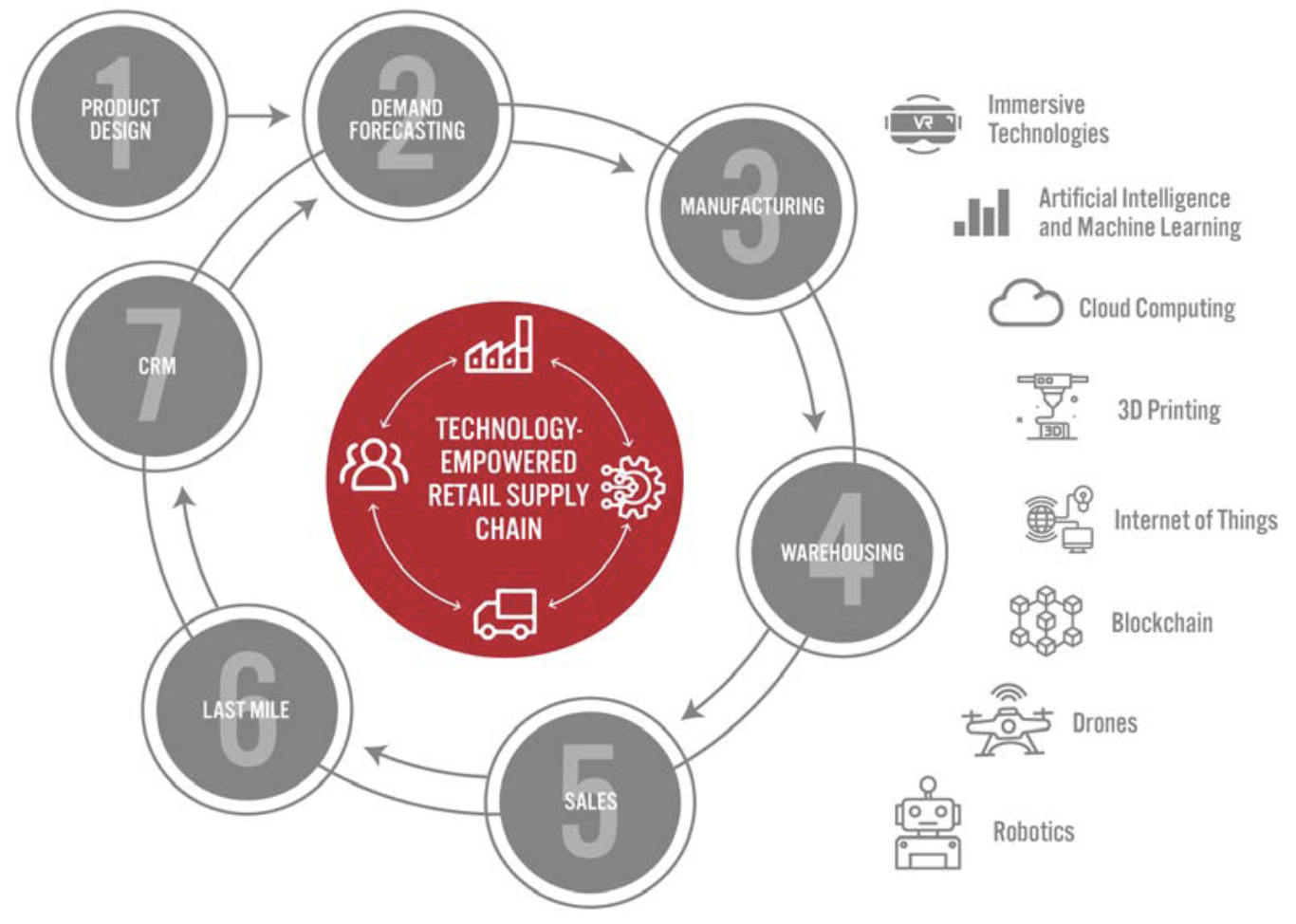

The Position of the Warehouse in the Supply Chain

The warehouse occupies the key location between the manufacturer and the retail store or consumer (in the case of dropshipping). The warehouse therefore acts as the gatekeeper after manufacturing, and the decisions and activities undertaken there have implications for the entire remainder of the supply chain, ultimately leading to the customer.

Figure 2. Product and Information Flow in the Modern, Technology-Powered Supply Chain [caption id="attachment_150923" align="aligncenter" width="550"]

Source: Coresight Research[/caption]

Source: Coresight Research[/caption]

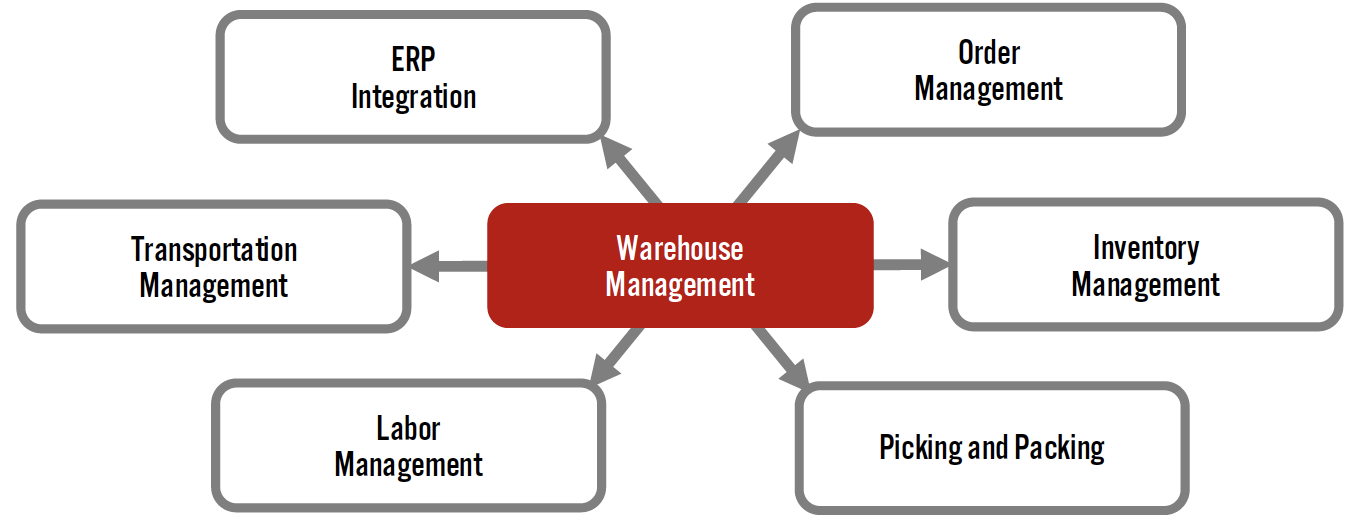

Functional Areas of Warehouse Management Platforms

Warehouse management centers on organizing stock-keeping units (SKUs) so that they are easily accessible to workers. SKUs can be organized according to size, inventory velocity/turnover, seasonality or other unique metrics. Ultimately, fast-moving SKUs should be located where they are easily accessible, and slow-moving SKUs should be relocated or eliminated.

The warehouse touches on many key operational areas within a retailer, as shown in Figure 3. Nearly every function within the warehouse has implications for customer satisfaction, because actions and decisions made there determine the ability to distribute goods to consumers in a timely fashion in an ever more-competitive environment. Additional benefits from effective warehouse management include reduced working capital needs, greater labor efficiency, more efficient energy consumption and reduced emissions of greenhouse gases.

The central location of the warehouse within the supply chain means that warehouse management software solutions must interface with other enterprise software platforms, such as enterprise resource planning (ERP), order management, inventory optimization and staffing management platforms. Since many warehouses employ human workers, the scheduling and management of labor is essential for efficient operation and meeting promised delivery times.

Figure 3. Functional Areas of Warehouse Management Platforms [caption id="attachment_150924" align="aligncenter" width="550"]

Source: Coresight Research[/caption]

Source: Coresight Research[/caption]

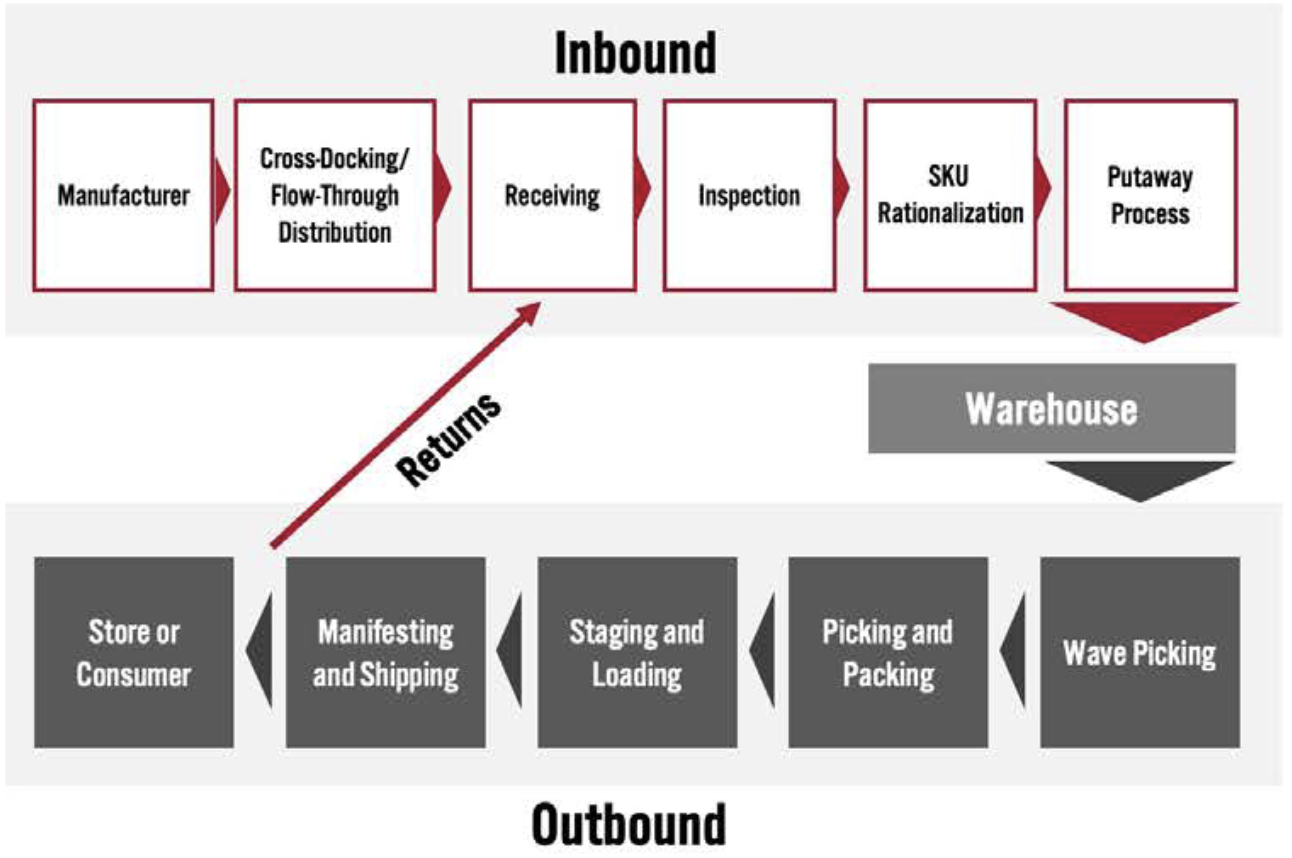

Warehouses receive goods from manufacturers and can also receive returns. One specific returns management platform is outlined in our report on opportunities in retail returns. Figure 4 depicts the flow of goods within and outside a warehouse. We define some of the processes below:

- Cross-docking/flow-through distribution involves goods going directly from receiving to shipping without having to be put away and packed.

- The putaway process involves storing items in the warehouse. Slotting is part of the putaway process, and refers to organizing items by velocity, dimensions, weight and product groupings to make picking and replenishment more efficient. (Inventory velocity refers to the speed at which inventory of a specific item is cycled within a specific period and is measured by inventory turns, which are equal to cost of goods sold divided by average inventory during a set period.)

- Wave picking is the assignment of groups of orders into short intervals (waves) to match orders to labor availability.

Figure 4. Flow of Goods within the Warehouse [caption id="attachment_150925" align="aligncenter" width="700"]

Source: Coresight Research[/caption]

Source: Coresight Research[/caption]

Enabling Technologies

The complexity of warehouses, which can contain thousands or even a million SKUs, lends itself to the benefits of cloud computing, which can access near-unlimited computing power, and AI/ML to make forecasts and find unseen relationships among large amounts of data. AI/ML can also support companies in achieving shorter or promised fulfillment times (for greater customer satisfaction), improving working capital utilization, maximizing profitability and enhancing sustainability. Warehouses also leverage 5G cellular or other networks to remain in contact with trucks and other vehicles in transit.

Warehouses are increasingly using robotics and automation to unload vehicles, and fetch and gather items within the warehouse. The use of automation and its effect on labor are tightly intertwined; often, robots and humans work optimally together in teams. One application of robots relates to preserving worker’s health: autonomous mobile robots such as Amazon’s Kiva robots or those from Fetch Robotics (to be acquired by Zebra Technologies) bring items to pickers and packers, eliminating the need for workers to walk back and forth (which can add up to many miles per day). Another worker-friendly technology is pick-to-light, which uses light emitting diodes (LEDs) to guide workers to items to be picked, reducing worker time and frustration in searching for items to pack.

Given the current labor shortage and workers’ avoidance of exhausting warehouse jobs, the deployment of labor-saving robots could improve the attractiveness of warehouse jobs to potential employees.

[caption id="attachment_150926" align="aligncenter" width="350"] Pick-to-light system

Pick-to-light systemSource: Honeywell[/caption]

One vision of the future is the “lights-out” warehouse, which staffs no human workers and operates entirely autonomously. In 2018, Chinese e-commerce retailer JD.com unveiled an automated warehouse outside Shanghai that employed just four humans with the capacity to process 200,000 packages daily.

Leading Warehouse Management Software Companies

The warehouse management software segment is dominated by large global enterprise/ERP software vendors, which we present in Figure 5.

Figure 5. Selected Large Warehouse Management Software Suppliers

[wpdatatable id=2105] *For the most recently completed fiscal year **Dematic revenues reported within parent company KION Group’s supply chain solutions segment Source: Company reports/XE.comThere are also several innovators that offer warehouse management system functionality:

- Fishbowl offers a business automation platform that manages picking, packing and shipping, as well as inventory and scrap management.

- InVia Robotics offers a warehouse automation SaaS (software-as-a-service) platform that uses AI to optimize productivity and workflows—for example, minimizing excess walking by human employees—as well as a warehouse execution system and picker robots.

- Verte offers a warehouse management system that aims to automate orders, improve inventory accuracy, reduce shipping time and costs, and speed up warehouse processes.

What We Think

The warehouse occupies a critical position in the supply chain, bridging the gap between manufacturing and fulfillment, and connecting to multiple operational areas.

Consumer demands on retailers continue to elevate: ever-shortening delivery times are putting more pressure on retailers to optimize efficiency to achieve operational and financial benefits.

Solution providers are offering AI-based tools to improve warehouse management process, such as by minimizing human movement to increase efficiency.

Implications for Brands/Retailers

- It is important for brands and retailers to drive efficiency and improvements in warehouse management, as it has direct impacts on customer satisfaction and therefore enhances revenues and profits.

- Faster fulfillment is important for brands and retailers to compete in a market with ever-shortening delivery times, with the continued rise of e-commerce and instant-needs retailers.

Implications for Real Estate Firms

- Demand for warehouse space remains strong due to rising e-commerce penetration and the need for faster delivery times.

- Retailers are operating smaller stores but moving fulfillment toward the consumer.

- Instant-needs retailers are using vacant retail storefronts as fulfillment centers.

- The warehouse management category is likely under-optimized due to its distance from the retail front lines.

- Vendors can target retailers of all size or offer niche solutions.

- New technologies such as AI enable continues to grow in capabilities, enabling focused new entrants to leapfrog incumbents.