Web Developers

Company Overview

Efficient processes to control the quality of production and to verify suppliers’ compliance to the standards set by the brands and retailers are crucial in a market in which retailers are competing to balance price, quality and speed to meet today’s consumer demand. However, most players in the apparel, accessories and footwear industry still largely rely on manual paper-based quality control and compliance monitoring processes, much of which are largely disconnected across the supply chain and prone to human error. Technology startup Inspectorio is one company that is disrupting the industry, using mobile, web and AI technologies to digitalize quality control and compliance monitoring processes across the apparel, accessories and footwear supply chains. Inspectorio’s vision is to have supply-chain data fed in real-time and dynamically to all the stakeholders within the supply chain—from brands and retailers, to vendors and factories, to inspection agencies—using AI to minimize risks and IoT and AI to minimize human intervention. Source: Inspectorio

Source: Inspectorio

The Beginning

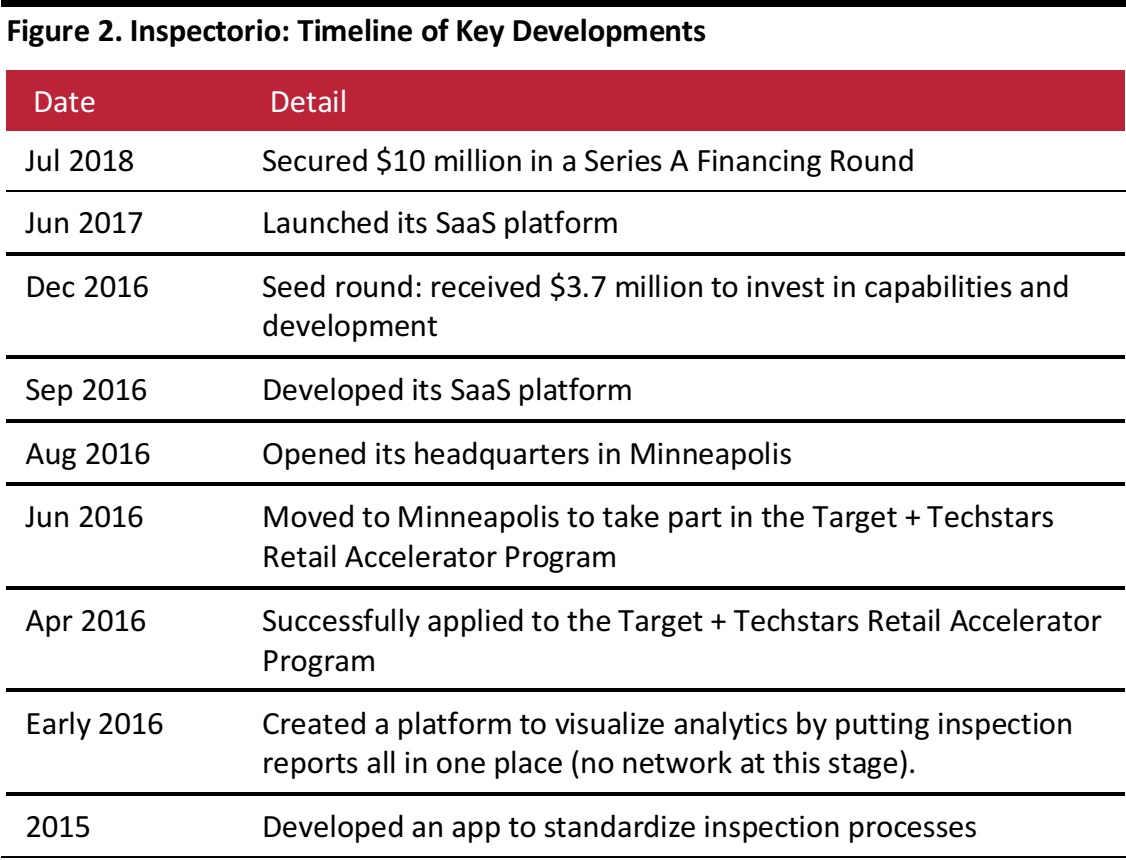

Inspectorio was founded in 2015 by a group of global professionals with experience working in apparel and footwear sourcing and supply-chain management in markets as diverse as Vietnam, China, Ecuador and the US. In April 2016, Inspectorio participated in the Target + Techstars Retail Accelerator Program and the following year, received a $3.7-million investment from Target. In 2018, the company secured a further $10 million in a Series A Financing Round. Source: Inspectorio

Source: Inspectorio

A Cloud-Based Web and Mobile SaaS Platform

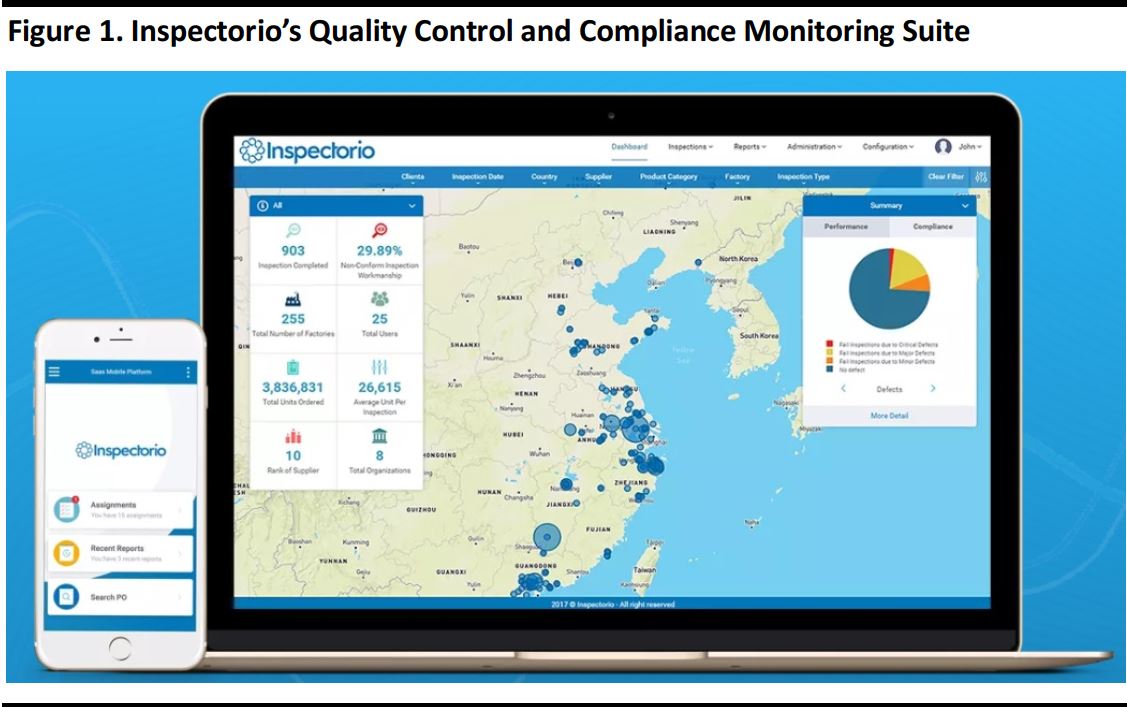

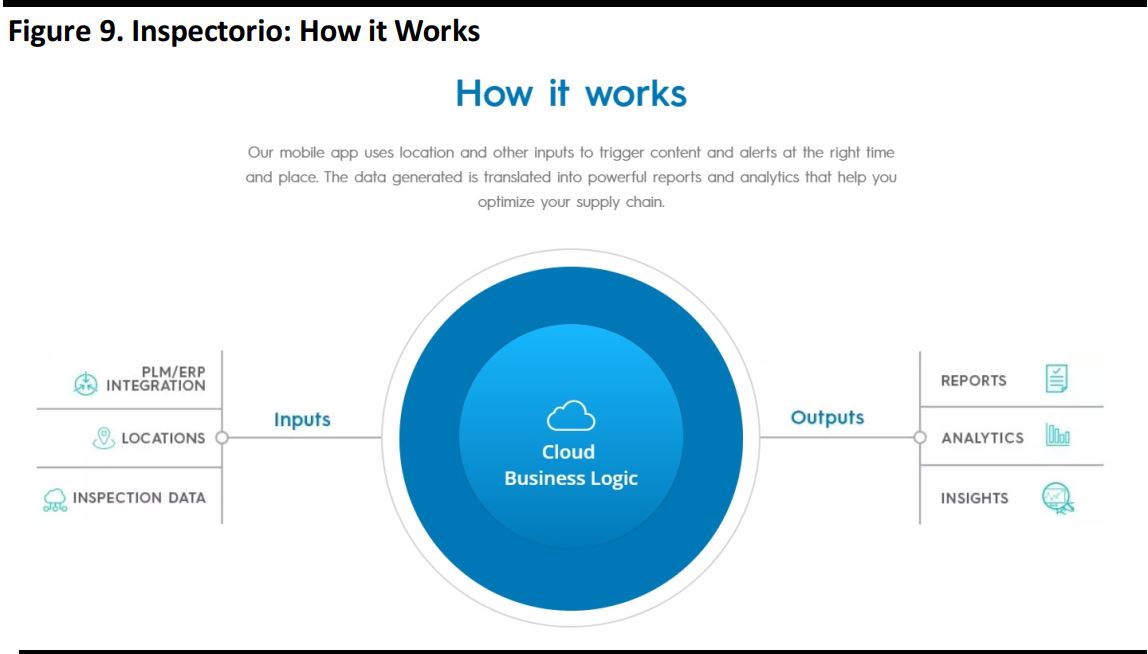

Inspectorio offers a cloud-based web and mobile SaaS platform that allows retailers, brands, vendors and factories to digitalize quality control and compliance monitoring processes through a system that uses the latest technology to help improve supply-chain efficiency, visibility and productivity. Inspectorio’s platform enables retailers and brands to build a digital ecosystem—a system in which they can collaborate and share data through digital technology in real-time with manufacturers, suppliers and inspectors—throughout their global supply chain. Managers can see the real-time activity feed and alerts of the inspection process and monitor inspectors in the field with live GPS tracking via a mobile application. The platform is a dynamic system that allows full customization of all quality control and compliance monitoring processes, and a completely automated service for booking, managing, monitoring and reviewing inspection results. The mobile app guides inspectors through the inspection process based on the client’s customized workflow. Inspectorio uses AI and machine learning technology to minimize the risk of negligence, unreported defects or corruption, by identifying high-risk areas for a supplier, factory or product category, and recognize fraudulent behaviors from the users.From Data to Analytics

Once an inspection is completed, data is immediately converted into an inspection report and delivered to all relevant parties, allowing for quick collaboration between retailers and vendors. Corrective action requests are automatically generated from the inspection report, allowing seamless communication within the platform. Inspectorio converts data generated during the inspection process into easily accessible analytics. Moreover, subscribers can access a broader data ecosystem that combines their data anonymously with the data of other subscribers. This allows customers to leverage knowledge from both within and outside their particular industry, and connect and collaborate with a new and broader network. As a result, the platform empowers subscribers to do business in a fundamentally new way. The company already helps leading retailers and brands to better understand their supply chain helping them to become more efficient, transparent and productive. As of July 5, 2018, Inspectorio’s technology is used by more than 2,800 organizations participating in supply-chain ecosystems of some of the world’s largest retailers, brands, vendors and factories, including US retail giant Target, department store company Kohl’s, Spanish clothing company Inditex and the world's leading inspection, verification, testing and certification company SGS.Industry Overview

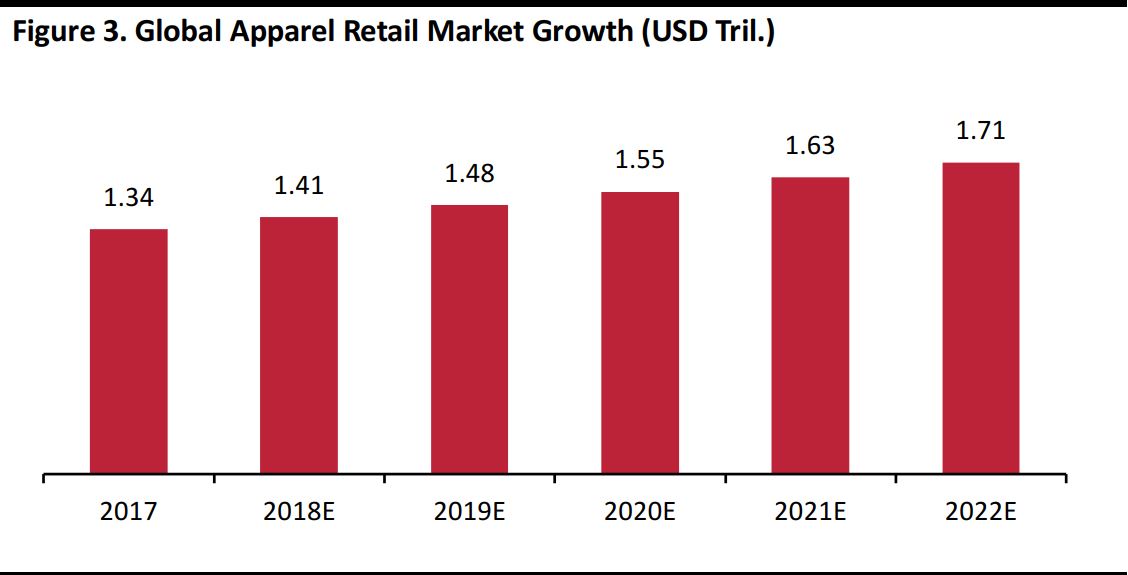

Inspectorio’s clients are part of the supply chain to the apparel industry, an industry that had a total global value of $1.3 trillion in 2017 and that is estimated to grow at a compound annual rate (CAGR) of 5% through to 2022, according to Euromonitor International. Source: Euromonitor International/Coresight Research

Source: Euromonitor International/Coresight Research

The Problems of a Fragmented Supply Chain

The apparel and footwear industry is still largely served by a fragmented supply chain—where manufacturers, suppliers and retailers work in silos with little coordination—that largely lags other industries in the application of technology aimed at process improvement. The fragmentation of the supply chain makes quality control and compliance monitoring very difficult for brands and retailers, but nevertheless is a process that is very important for companies. Ensuring the efficiency of this process is very important for brands and retailers to guarantee quality standards at attractive prices to consumers and speed to market, and to avoid reputational damage caused by being associated with production facilities with poor working conditions or having a negative impact on the environment:- Quality: Brands and retailers need to ensure that the products they sell always meet the quality standards expected by their customers. Sourcing from different production facilities can make it harder for brands and retailers to retain control of the quality of the output from different suppliers. The overall quality of apparel and footwear items has seen a consistent decline over the past 10 years—particularly due to the rise of fast fashion—according to industry experts. This is due to the increasing pressure that retailers and brands are under to deliver product lines to consumers faster and at lower prices.

- Price: Price pressure is a concern for 98% of operators in the apparel and footwear industry, according to an online survey undertaken in 2018 by specialist publication Sourcing Journal, which surveyed 380 operators in the apparel, footwear and accessories industry globally. One respondent noted how the prices of inputs are rising, while retail prices are either stagnating or decl This has put a lot of pressure on increasing the efficiency of the supply chain.

- Speed to market: Shorter fashion cycles make speed to market ever-more important for brands and retailers. However, speed to market is often hindered by inefficiencies in the supply chain. The fragmentation of the supply chain makes it difficult for brands to coordinate their sourcing network. Speed is a key factor for the industry. Pressure to deliver goods on time was identified as a key concern for 68% of the respondents to the Sourcing Journal’s survey, and, according to one respondent, the focus on speed, which is key to remain competitive in a fast-fashion environment, is leading product development teams to focus less on the due diligence that needs to be executed prior to confirming programs with suppliers.

- Working conditions/ethical sourcing: Consumers are more than ever concerned about ethical manufacturing and product provenance. For example, earlier this year, 70,000 consumers globally signed a petition—as part of the #GoTransparent campaign—to ask brands including Walmart, Primark, Forever 21 and Urban Outfitters to increase the transparency of their sourcing operations. As a result, Primark published a map of the manufacturers that have produced items for the retailer for at least one year and have since become established suppliers.

- Environmental impact: Sustainability is particularly important for the fashion industry, as apparel manufacturing can have a significant impact on the environment, given its intensive use of resources, chemicals and energy. Moreover, the apparel industry operates a global supply chain, with parts of the production outsourced and under heavy cost pressure to operators in countries where environmental regulations tend to be less restrictive than in more-mature markets. On the other hand, retailers and brands cannot compromise when it comes to the impact of their operations on the environment. In today’s world, information travels fast and corporate accountability is expected, and cutting corners in terms of environmental sustainability risks damaging the image of the company.

How to Make the Supply Chain More Efficient

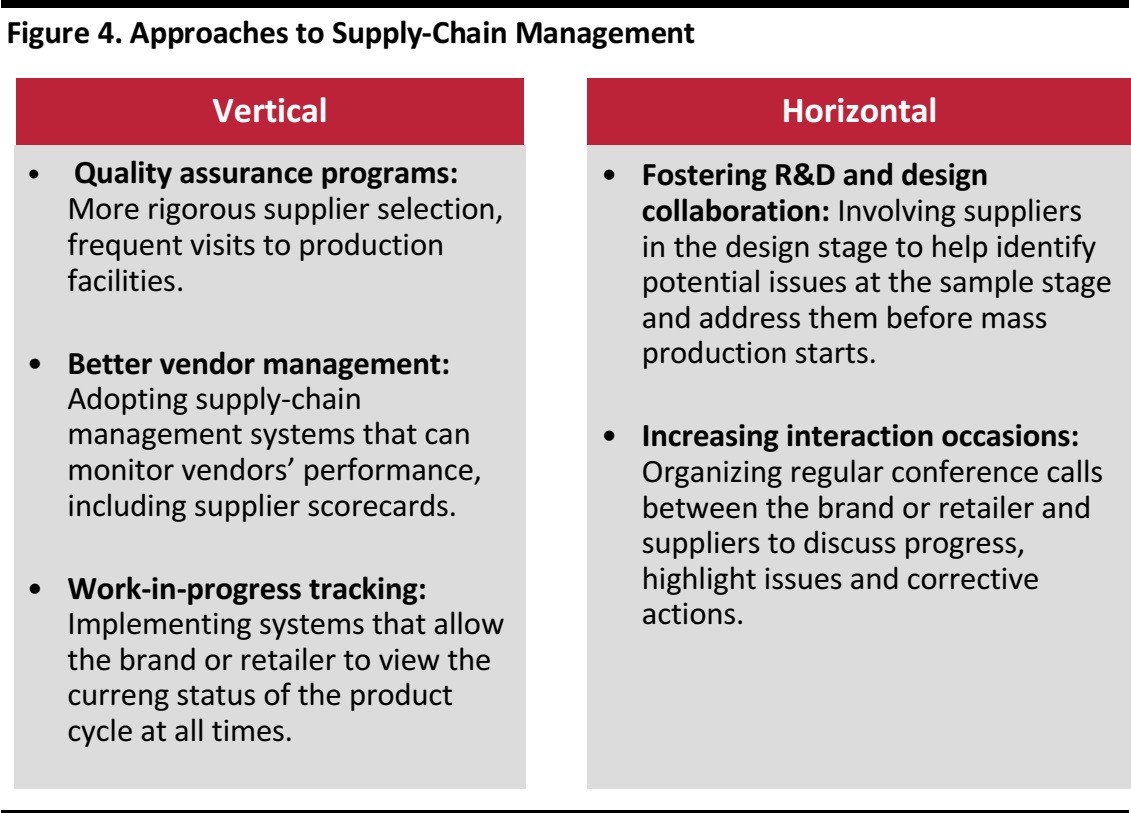

Enhancing transparency and fostering collaboration among partners within the supply chain are considered as key factors to make the product cycle more efficient by the decision makers within the apparel and footwear industry. Transparency: Some 46% of respondents to the 2018 Sourcing Journal survey said transparency is a key factor for the apparel and footwear industry. Lack of visibility within the apparel and footwear supply chain can impact all of the abovementioned points. Transparency issues can arise as coordination is made more complicated when brands and retailers use a large number of suppliers to ensure orders are met. Corruption at the inspection level and outsourcing practices undertaken by some suppliers also hamper transparency. Fostering coordination and collaboration by using both vertical and horizontal approaches: Employing different suppliers at different stages of the product cycle means that fostering coordination and collaboration within the supply chain is even more important to avoid inefficiencies that can hinder quality, speed to market and ethical and environmental sustainability. To this end, brands and retailers use a blend of vertical and horizontal approaches to foster coordination and collaboration throughout the supply chain.- Vertical approach: With the vertical approach, the retailer at the top of the supply chain tightens control over the other parts of the system—this includes quality assurance programs, better vendor management and work-in-progress tracking.

- Horizontal approach: With the horizontal approach, the retailer encourages collaboration among suppliers by fostering research and development (R&D) and design collaboration, and increasing the number of occasions for interaction. Figure 6 summarizes the two approaches.

Source:Coresight Research

Source:Coresight Research

Supply-Chain Management Still a Manual Process

Combining both vertical and horizontal approaches can help retailers and brands maximize efficiencies in the product cycle. By implementing vertical systems, a retailer or brand can ensure a consistent standard of production and spot issues as they occur. The horizontal approach is a useful complement to such hierarchical control. Collaboration within the supply chain is key to ensure quality control and speed to market, according to industry contacts. A collaborative horizontal approach allows retailers to more effectively coordinate the different parts of the supply chain by strengthening synergies among suppliers. The use of digital technologies such as supply-chain management software, cloud-based systems and video conferencing would significantly help brands and retailers to effectively adopt both vertical and horizontal approaches to product cycle management. However, quality control and compliance monitoring—a crucial process to reduce inefficiencies and deliver quality, low cost and speed to market—still largely rely on outdated, manual paper-based processes that are still based on spreadsheets, which leaves global supply chains largely disconnected, prone to lack of transparency and subject to inefficiency, inaccuracy and risk. Some 43% of respondents to the 2018 Sourcing Journal survey said that they still rely on manual paper-based quality control and compliance monitoring processes. The majority of respondents—66%—have partially digitalized and use a combination of manual and digital tools. A minority—just 14%—have gone fully digital, with the adoption of software or cloud-based systems to manage their quality control and compliance monitoring processes.Different Inspection Models

Source: Inspectorio

Source: Inspectorio

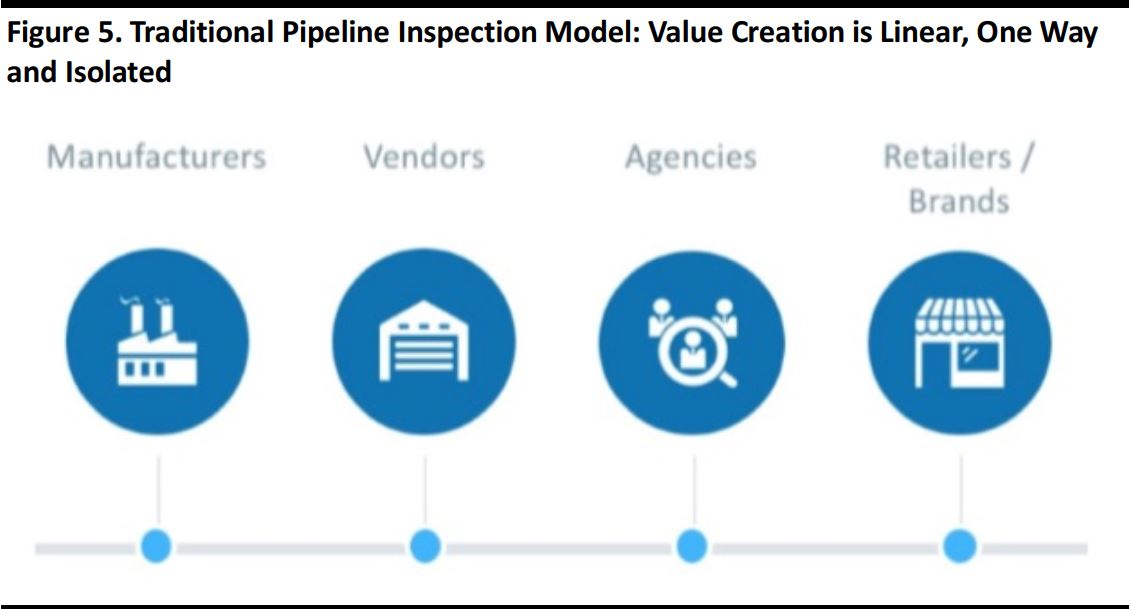

Traditional pipeline inspection model: This model, illustrated above, is a largely slow, disconnected, manual process that may suffer from lack of transparency. The interdependency of the different parts of the supply chain makes the linear approach shown above largely inadequate to equip retailers and brands with an efficient supply chain able to respond quickly and effectively to increasingly shorter fashion cycles.

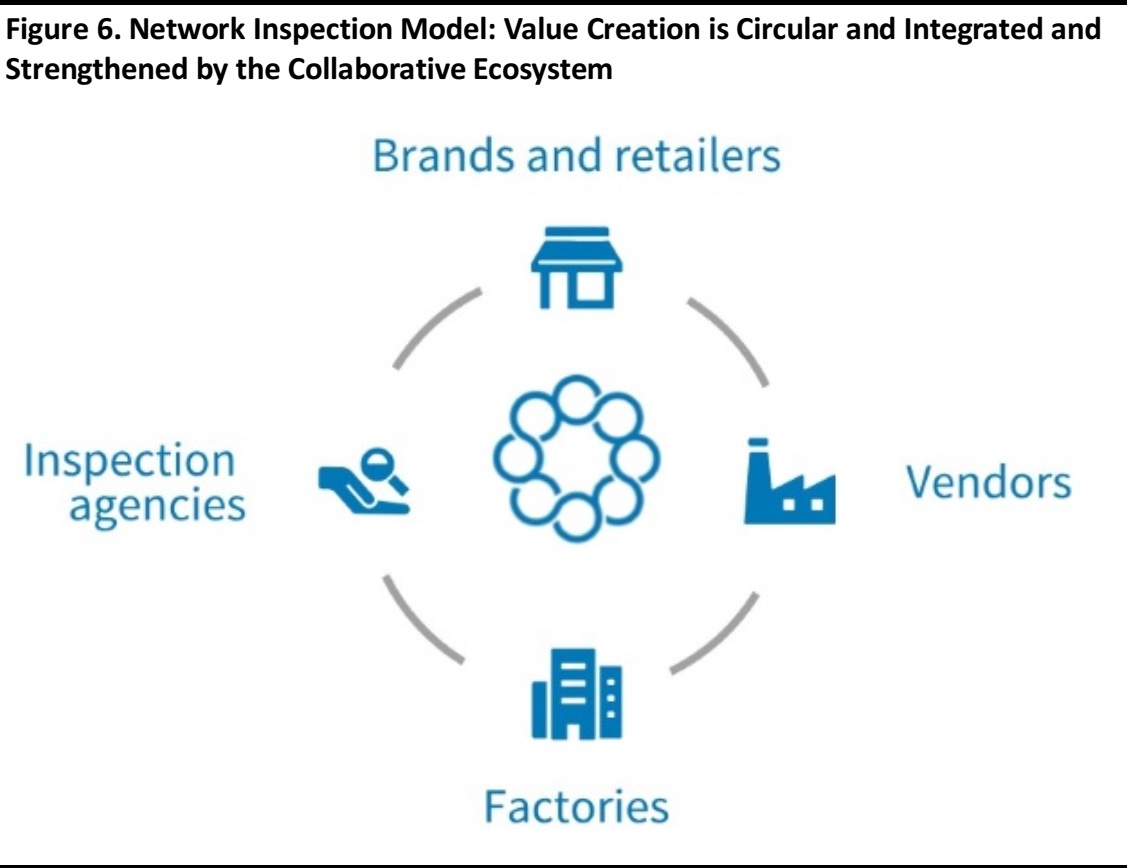

Network inspection model: A network inspection approach, that sees quality control and compliance monitoring executed from the beginning of the sourcing process and information fed in the network at all stages, is the one that companies should adapt to increase efficiency. This approach, which is enabled by technology such as Inspectorio’s, is illustrated in Figure 6.

Source:Inspectorio

Source:Inspectorio

Areas in Need of Innovation

Apparel and footwear companies are aware that there is both the need and scope for further improvement of the quality control and compliance monitoring processes of their supply chains. The fact that respondents to the Sourcing Journal survey gave a score of 6.8 out of 10 points to their current quality control and compliance monitoring processes illustrates this point. Corrective action requests: This was the area identified as most in need of innovation by 55% of respondents to the Sourcing Journal survey. This area is crucial to identify and rectify an issue before the supply chain is compromised down the line. Inspection transparency: Another main area in need of innovation was inspection transparency, as identified by 55% of respondents to the Sourcing Journal survey. Among respondents, 20% are not confident about what is taking place at different levels of the supply chain, and feel that better reporting and analytics related to the inspections would help to identify patterns and trends and spot issues earlier along the supply chain. In particular, the analysis of real-time data would significantly help supply-chain operators to identify issues as they occur and to minimize their impact by rectifying the problems as they occur. Data analysis and sharing: Some 46% and 45% of the survey respondents identified data analysis and sharing as areas in need of improvement. Digitalization: The industry is moving quickly towards digitalization, leaving behind years of slackness, during which operators continued to rely on manual processes. Investment in digital technology can surely help the integration of the entire development and production process. Half of the respondents to the Sourcing Journal survey said that their company is currently investing in digitalizing and improving quality control and compliance monitoring processes. Only a minority—21%—said that they have no plans to invest in this area. As the industry moves quickly towards digitalization, companies that do not invest in innovation will lag behind those that realize the use of digital technology will improve the transparency, efficiency and productivity of the entire supply chain.Inspectorio’s Offerings

Inspectorio offers a cloud-based web and mobile SaaS platform that allows retailers, brands, vendors and factories to digitalize quality control and compliance monitoring processes. The platform uses the latest technology, including AI and mobile, to improve supply-chain efficiency, visibility and productivity. Inspectorio’s service includes the following components:- Quality control and a supplier compliance verification platform: The SaaS platform gives operators within the supply chain real-time access to reporting information. This results in a digital process that improves efficiency, transparency and traceability.

- Compliance verification platform using mobile technology: The web-based platform can be controlled via a mobile app. This is very important in supply-chain verification operations, where it is necessary to collaborate with supply-chain partners in remote locations. The mobile app enables geolocalization and the input of real-time information gathered on-site. Inspectors can seamlessly follow the quality and compliance verification process step-by-step and instantaneously submit inspection reports and corrective action requests.

- Supply-chain analytics: Data generated during the inspection process are converted into analytics. Inspectorio’s subscribers can access a broader data ecosystem that combines their data anonymously with the data of other subscribers. This allows customers to leverage knowledge from peers both within and outside their particular industry to generate predictive analytics and help identify problems before they occur.

- Booking: The user can view lists of inspection booking details, get purchase order (PO) data and convert bookings into inspection assignments.

- Assignments: The user can view a list of assignments, edit, schedule and assign them to inspectors, vendors or factories for self-inspection.

- Inspection execution: Inspectorio’s suite enables the inspector to replace inefficient manual paper-based processes, and begin collecting accessible data by conducting inspections via a mobile app.

- Report management: Inspectorio’s SaaS platform gives users access to a centralized record of all inspection reports and enables them to run filter searches by product category, factory, vendor or country.

- Corrective action requests: Inspectorio’s software generates automatic corrective action requests from the inspection reports and sends them to the factory once the report is uploaded. Factories can fill out information directly using the platform.

Source: Inspectorio

Source: Inspectorio

Inspectorio employs AI to analyze data that has been fed into the system for predictive and prescriptive capability, including:

- Defect prediction: Based on the collected data, Inspectorio is able to predict at which stage of the supply chain potential product failures or defects will occur. Traditionally, risk assessment was limited to the experience and knowledge of the human inspector. Inspectorio moves the defect prediction function from relying on a single inspector to one based on a large amount of data that are fed into the system and analyzed through AI.

- Risk assessment: Based on the performance of a facility, Inspectorio can identify the likelihood of that production site not meeting the quality standards of a particular buyer, and the likely future performance of that production facility. This allows companies—large brands or retailers that need to inspect thousands of sites in particular—to decide which facilities require direct inspections and which can be trusted for self-assessment.

- Fraudulent behavior monitoring: Inspectorio’s technology can predict fraudulent behavior by inspectors based on inspection results and on how an inspection is performed, by considering factors such as the time per piece, or how the results have been changed during the inspection. The platform can also highlight the risk of inspectors not being transparent about the inspection results by looking at the historical performance over a period of time. For example, the easiest way for a facility to not fail an inspection is for an inspector to declare defects that are close to the maximum allowed level—most inspectors are aware of the maximum number of defective goods that is considered acceptable. Inspectorio’s AI-powered analytical capability can identify inspectors that regularly declare defects just below the maximum allowed threshold as at higher risk of fraudulent behavior.

Source:Inspectorio

Source:Inspectorio

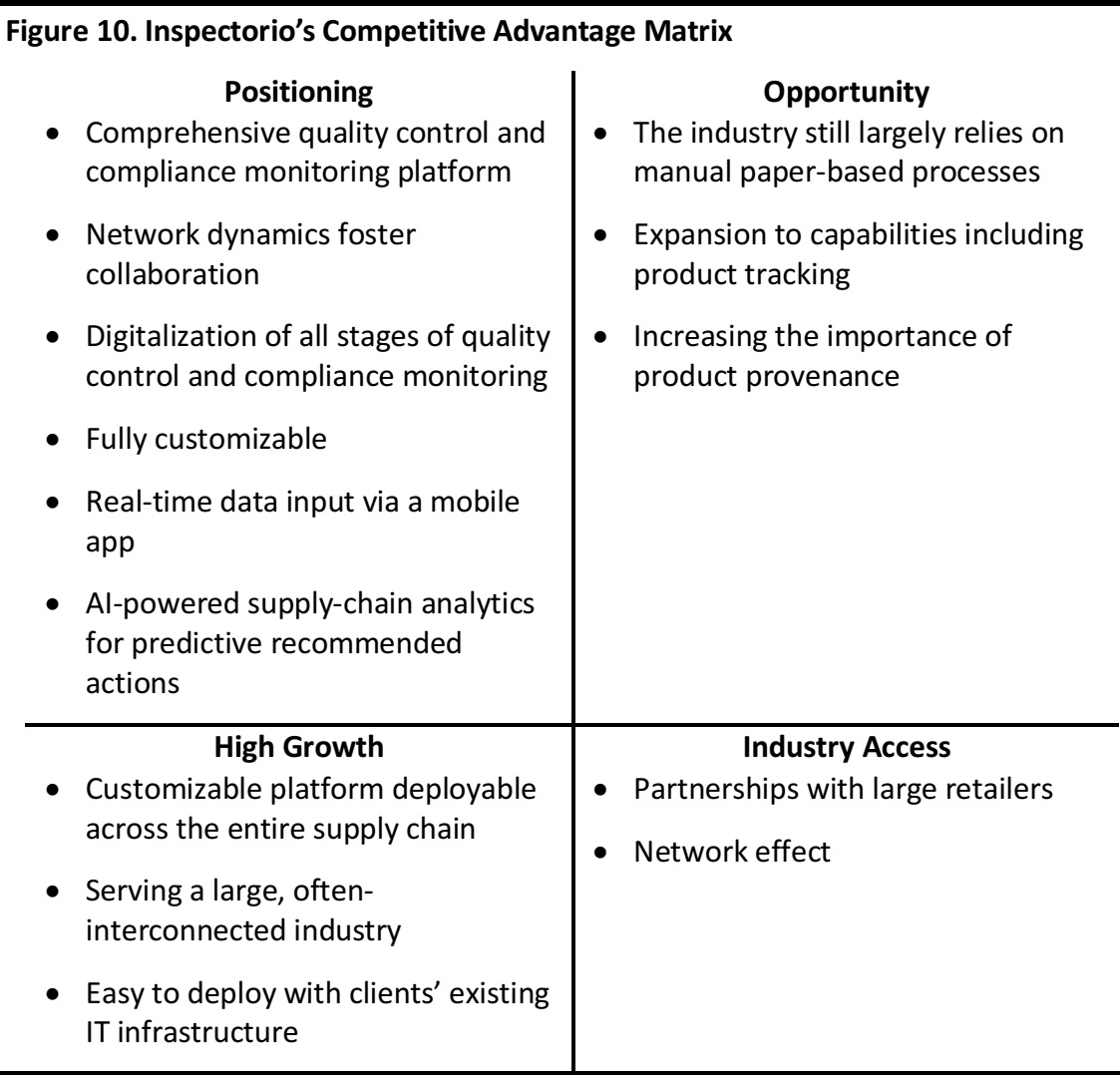

Competitive Advantages

Inspectorio considers itself the most-advanced and most-well-established quality control platform, with its network dynamics differentiating it from other systems. Inspectorio offers digitalization of the quality control and compliance monitoring process with an all-round service, which it believes is unmatched in the market. Source: Inspectorio

Source: Inspectorio

Compared to competitors, Inspectorio offers a fully-integrated quality control and compliance monitoring platform which is fully customizable and digitalizes the entire supply-chain process through the following features:

- Customizable workflow: Inspectorio allows inspections to be executed according to customizable rules and processes set by the user, providing accountability and ensuring quality control is aligned with expectations.

- Real-time monitoring: Inspectorio enables stakeholders within the supply chain to collaborate and share data in real time. Managers can see the real-time activity feed and use GPS to monitor inspectors undertaking inspections via a mobile app.

- Digitalization of all processes: Inspectorio enables the digitalization of all quality control and compliance monitoring processes, including planning, booking, execution, corrective actions requests and implementation.

- Network dynamics: Inspectorio can be used by all stakeholders within the supply chain—manufacturers, suppliers, vendors, distributors, inspection agencies, brands and retailers—creating a network that increases collaboration and connectivity between all parties and delivering greater operational efficiency.

- Geolocalization: Local data gathering enables the creation of different reports for different parties which is fed in real time and shared among the stakeholders within the supply chain.

Source: Coresight Research

Source: Coresight Research

By serving an industry that has long resisted the implementation of more modern and efficient operations, Inspectorio could face the following challenges:

- Lack of consensus: To be effective, a system to manage the digital supply chain requires the consensus of all partners in the product cycle to share the digital information and the This is not always easy, as suppliers and vendors in the supply chain may be reluctant to share information with other parties that might be working together in a given product cycle, but could be a competitor in another.

- Costs: The reason more efficient and modern quality control and compliance monitoring systems have not been adopted has often been due to an unwillingness to invest resources beyond what is strictly needed for production. This is due to the cost-sensitive nature of the apparel and footwear supply chain that is under pressure to deliver products at the lowest price possible. However, in the long term, failing to invest in the digitalization of supply-chain management and control processes will result in less cost-effective and less-competitive operations.

- Resistance to new approaches: The apparel and footwear supply chain is often operated by people that have long relied on manual systems (i.e., pen and paper and spreadsheets) and that might be resistant to innovations, either because they think they might be too difficult to implement, require learning a new way of doing things or because they are unfamiliar with the use of new devices.

Case Study: Target

In October 2017, US retailer Target announced it was adopting Inspectorio’s digital platform to conduct factory inspections. It teamed up with Inspectorio to roll out the digital quality control and compliance monitoring technology to 50 of Target’s vendors across Vietnam, Cambodia and Thailand, a network of more than 100 factories that represents more than a quarter of the retailer’s apparel and accessories business. With the adoption of Inspectorio’s digital platform, Target aims to reduce quality control inspection time by up to 50%. For example, it normally takes up to a week for an inspection report to be generated, a corrective action plan triggered and the results communicated between parties, whereas by digitalizing the process with Inspectorio, the whole process can take just three days. With the implementation of Inspectorio’s technology across its apparel and accessories supply chain, Target also aims to improve the transparency of its product cycle and strengthen its commitment to responsible sourcing. Delivering consistency and quality is another key aspect that Target is aiming to enhance through its partnership with Inspectorio. At the same time, Inspectorio’s digital platform is helping Target to identify issues and diagnose causes in real-time and to trigger responses prior to something negative happening at some point down the line in the product cycle. The transparency within the supply chain obtained as a result of the adoption of Inspectorio’s technology is allowing Target to make real-time decisions about its products and is helping the retailer to improve the consistency and quality of the products it offers to its customers, according to Irene Quarshire, Target’s VP of Product Quality and Responsible Sourcing. The data analytics from Inspectorio’s platform is empowering Target to enhance its supply chain. Inspectorio’s software analytical capabilities get more powerful with use and as more data is fed into the platform. This enables Target to better identify best-in-class vendors and to hand over more quality control responsibilities to them, giving Target more time to focus on the product development stage, according to Quarshire. The collaboration between the retailer and Inspectorio began when the tech company applied to the Target + Techstars Retail Accelerator Program in April 2016.Business Model

Inspectorio earns revenues through a recurring subscription SaaS model on different levels based on the services provided:- Enterprise: Includes all of Inspectorio’s platform capabilities, including AI for task optimization, defect recommendation and risk prediction.

- Pro: A robust set of features including customizable workflows, booking forms, inspection reports and inspector evaluations.

- Standard: Self-inspection capabilities for vendors and factories connected to a Pro or Enterprise Plan.

- Essential: Enables factories to book inspections, have access to analytics and receive corrective and preventive actions plans.

Go-to-Market Strategy

Inspectorio is utilizing two main strategies to reach its target market:- Direct-to-merchant execution: Inspectorio is using its industry partnerships and access to senior retail executives to make its differentiated offering available to major merchants.

- Network effect: Production sites supplying to Inspectorio’s clients are often suppliers to other brands and retailers, and are also part of the network within the supply chain, together with other manufacturers, suppliers, distributors, vendors and inspection agencies. These other stakeholders and competitors see the advantages of using Inspectorio’s technology to maximize quality control and compliance monitoring and, in turn, decide to adopt Inspectorio’s suite for their own operations.

Competitive Landscape

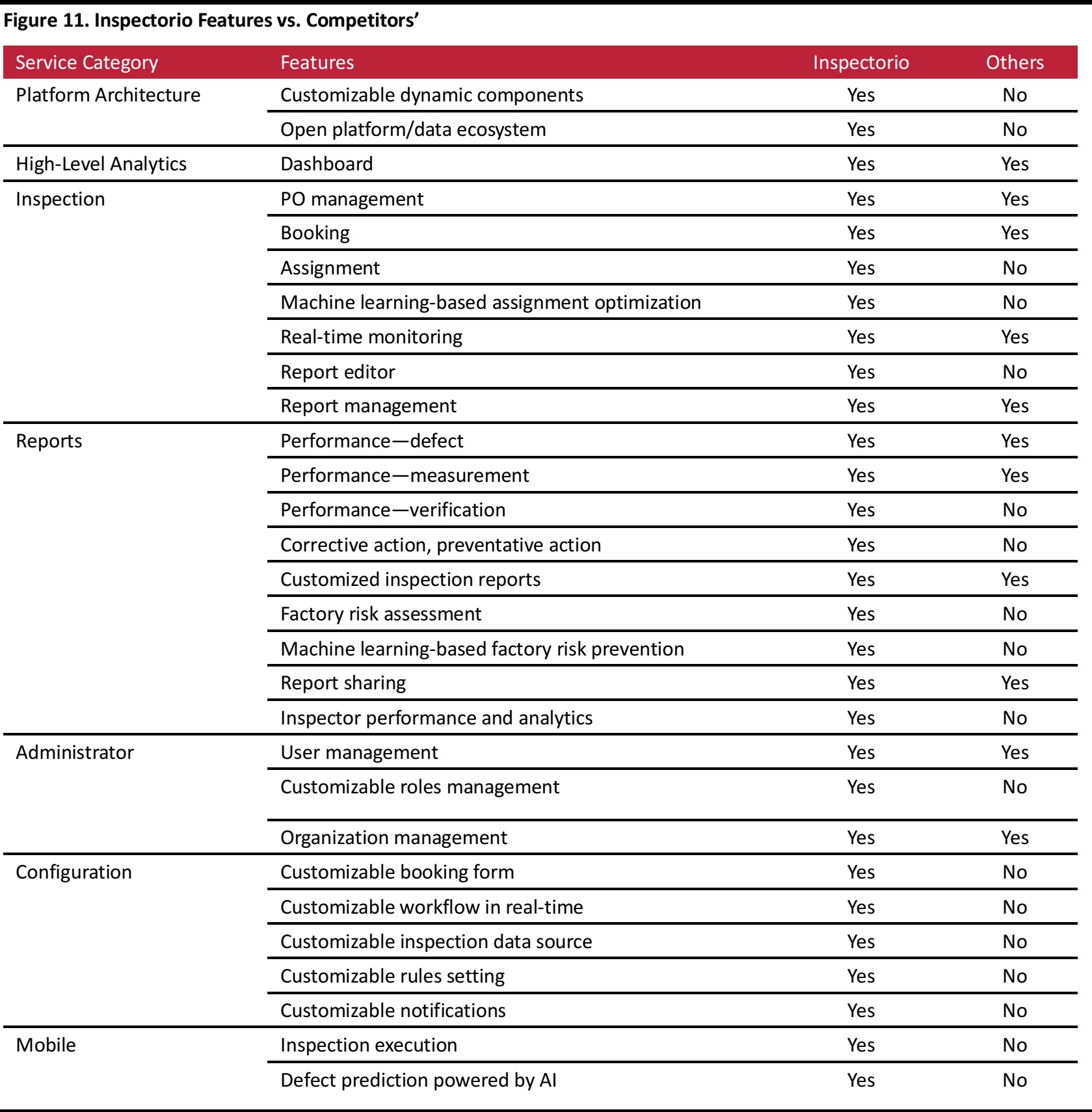

Inspectorio believes that, even when combined, no other company in the marketplace can compete with its robust feature set for quality control and compliance monitoring. Figure 11 shows how Inspectorio’s suite compares to its competitors’ offering. Source:Inspectorio

Source:Inspectorio

Key Management

Inspectorio’s founders and key management have decades of global experience working in apparel and footwear sourcing and supply-chain operations in diverse markets such as Vietnam, China, Ecuador and the US. Inspectorio’s management team includes:- CEO and Cofounder Carlos Moncayo Castillo: Currently based in Belarus, Carlos Moncayo Castillo is also Cofounder of Asiam Business Group, a Hong Kong-based organization that aims to facilitate business relations between Asia and Latin America. He has an Executive MBA from Kellogg-HKUST, and was named Young Global Leader by the World Economic Forum and selected as Best Young Entrepreneur in Asia in 2009 by Business Week Magazine.

- Managing Director and Cofounder David Klein: Currently based in Vietnam, David Klein has a Master’s degree in International Development from Cornell University and is also a Board member of Asiam Business Group.

- Managing Director, Chief Sales and Marketing Officer and Cofounder Fernando Moncayo Castillo: Currently based in the Minneapolis, Minnesota, US, Fernando Moncayo Castillo is also Cofounder of Asiam Business Group and Startups Ventures. A graduate of the Entrepreneurship Development Program at Massachusetts Institute of Technology, he is also a Singularity University Alumni, holds an EMBA from IDE Business School and was a member of the World Entrepreneurship Forum representing Ecuador.

- CTO Jonathan Bardin:Before joining Inspectorio, Jonathan Bardin was Chief Architect at software development firm TINYpulse and before that he was CTO at software development company Transcosmos Technologic Arts. He also worked as a research engineer on several projects funded by the French government and the European Union (EU), and was a visiting scholar at the University of California Riverside and National Institute of Informatics in Japan.

- COO and Cofounder Luis Moncayo Castillo: Currently based in the US, Luis Moncayo Castillo is also a mentor at startup accelerator Techstars, and Cofounder and Board member of Asiam Business Group.

Company Future Outlook/Upcoming Announcements

Leveraging its existing technology, Inspectorio is planning to expand its capabilities beyond quality control and compliance monitoring. Plans are in the works to launching its continuous improvement platform, a holistic product suite that will enable companies to strengthen the environmental and social sustainability of their supply chain and to further improve product quality by digitalizing quality assurance, including all quality-related activities done in-factory, from raw material checks to end-of-line evaluations. According to a company announcement, over 3,000 companies will be implementing the continuous improvement platform in the fourth quarter of 2018. Expansion of its platform capabilities will include production tracking and responsible sourcing verification, and will use IoT technology for the verification of manufacturing location and the unstaffed management of production sites:- Production tracking: In the next few months, Inspectorio will launch a production tracking capability that will enable factories to update time and action plans directly on the platform and making this information available to the vendor or retailer. The data in the platform will also allow the automation of the booking and inspection process. The platform will continuously collect updates of the various commitments, based on which the retailer will be able to define a specific rule and time by which the activity needs to be performed. For example, at the initial sewing stage in an apparel production scenario that lasts three weeks, the retailer can estimate that by the end of the first week, 20% of the production will be finalized, at which time an inspection could be undertaken. After the first inspection, the data collected by the system about the planned dates versus the actual dates allows the platform—using machine learning—to predict the likelihood of the factory being able to meet the delivery dates.

- Responsible sourcing: In the next three months, Inspectorio will launch a responsible sourcing platform for environmental and social compliance monitoring. The platform will allow retailers or brands to invite the factories they collaborate with to meet the standards they are to be evaluated on, based on a specific timeline and rules that the retailer or brand will define. The system will allow retailers to request factories to complete a preliminary self-assessment, followed by a verification. The Sustainable Apparel Coalition’s Higg Index—the most established standard in apparel and footwear for assessing environmental and social sustainability throughout the supply chain—is an example of the standard the new system will use.

- IoT for the verification of manufacturing location: Inspectorio plans to introduce an IoT-based system that will use devices—GPS and Beacon—placed in factories to securely verify the location of an inspector. The IoT system at the production facility will continuously send signals with location coordinates that are registered in the cloud. As the inspectors’ mobile app connects with the cloud, it verifies the specific location of the inspector. While the current Inspectorio platform is already able to locate inspectors through mobile technology, the new feature will enable the inspector’s mobile app to be associated with the location of the facility through the cloud, eliminating the possibility of manipulation. Currently, there are different ways to manipulate GPS locations, such as software that can artificially alter the location, but Inspectorio’s new feature will make this impossible.

Coresight View

Retailers and brands are under pressure to balance quality, price, speed and sustainability in order to meet consumers’ preferences and to remain competitive. In such an environment, effective quality control and compliance monitoring is key to reduce inefficiencies in the supply chain and to deliver a production cycle that can ensure the standards of quality and sustainability are met at the expected time and cost. Quality control and compliance monitoring in the apparel, accessories and footwear industry is complicated by the fact that the supply chain is often very fragmented, with retailers, inspection agencies, vendors and manufacturers located in different and distant parts of the world. Moreover, the emergence of fast fashion, with shorter fashion cycles, is encouraging further fragmentation and practices such as outsourcing at the production level to deliver on time and at lower cost. Employing different suppliers at different stages of the product cycle means that fostering coordination and collaboration within the supply chain is ever more important to avoid inefficiencies. However, the management of the apparel, accessories and footwear supply chain, as well as the quality control and compliance monitoring still largely rely on outdated manual paper-based processes, leaving the supply chain largely disconnected, prone to lack of transparency and subject to inefficiency, inaccuracy and risk. The use of digital technologies such as supply-chain management software, cloud systems, AI and IoT could significantly help brands and retailers to effectively coordinate their supply chain. Companies recognize this, and many industry players are investing in improving their supply-chain management and quality control and compliance monitoring processes through digitalization. Inspectorio offers a complete, scalable, customizable, easy-to-implement suite that helps retailers and brands to digitalize their entire supply chain, making it more efficient and boosting their competitiveness. For retailers and brands, empowering their operations by working with a technology provider such as Inspectorio could be crucial to maintaining and strengthening their positioning against competitors in an industry that is moving quickly towards digitalization.Company Contact Fernando Moncayo Castillo, Chief Sales and Marketing Office and Cofounder Inspectorio, Inc. fernando@inspectorio.com www.inspectorio.com