EXECUTIVE SUMMARY

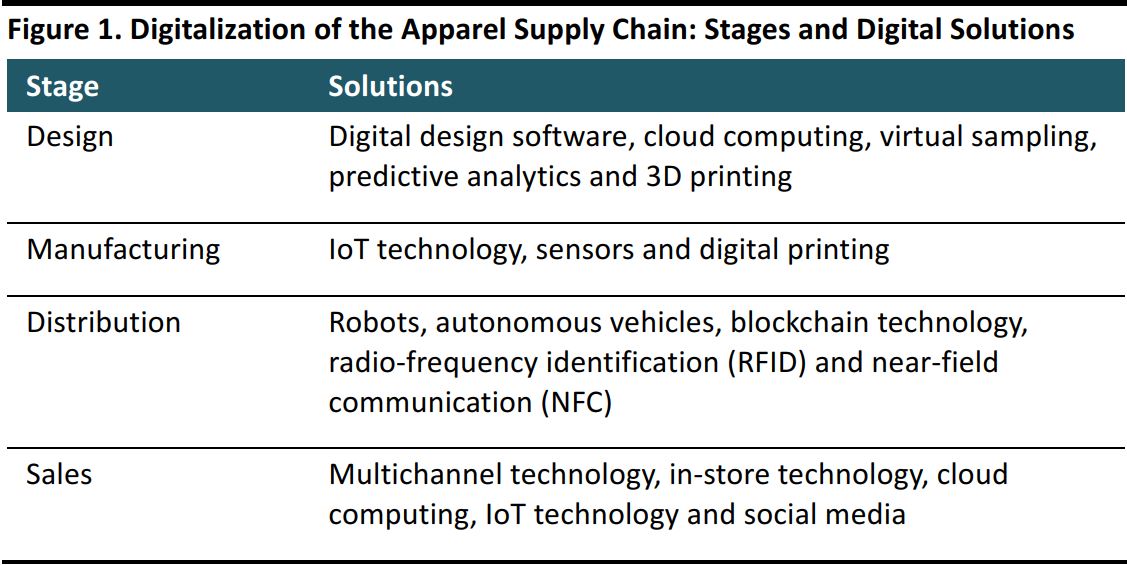

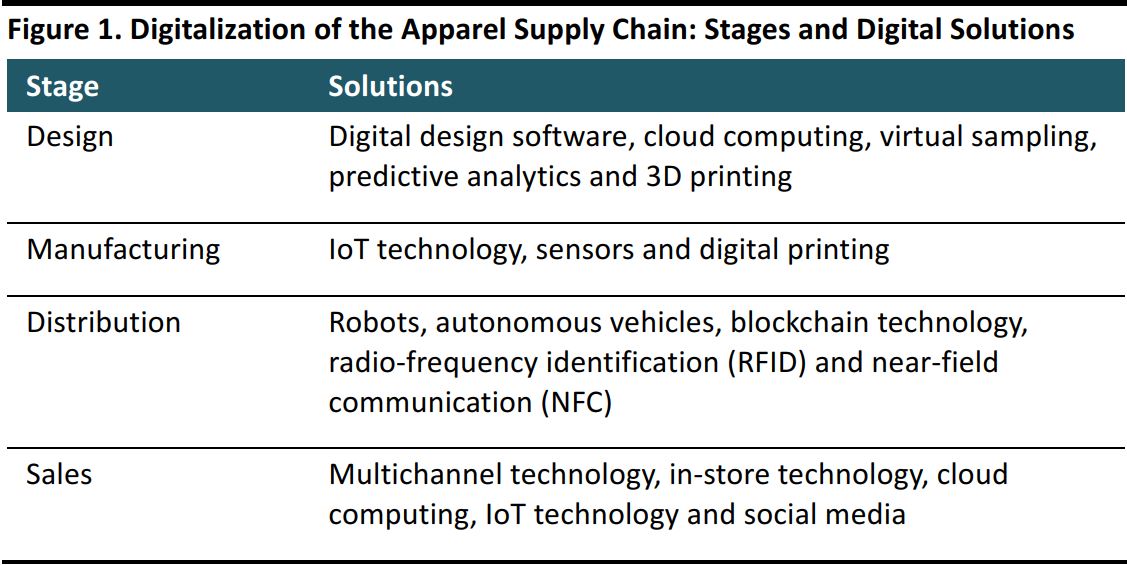

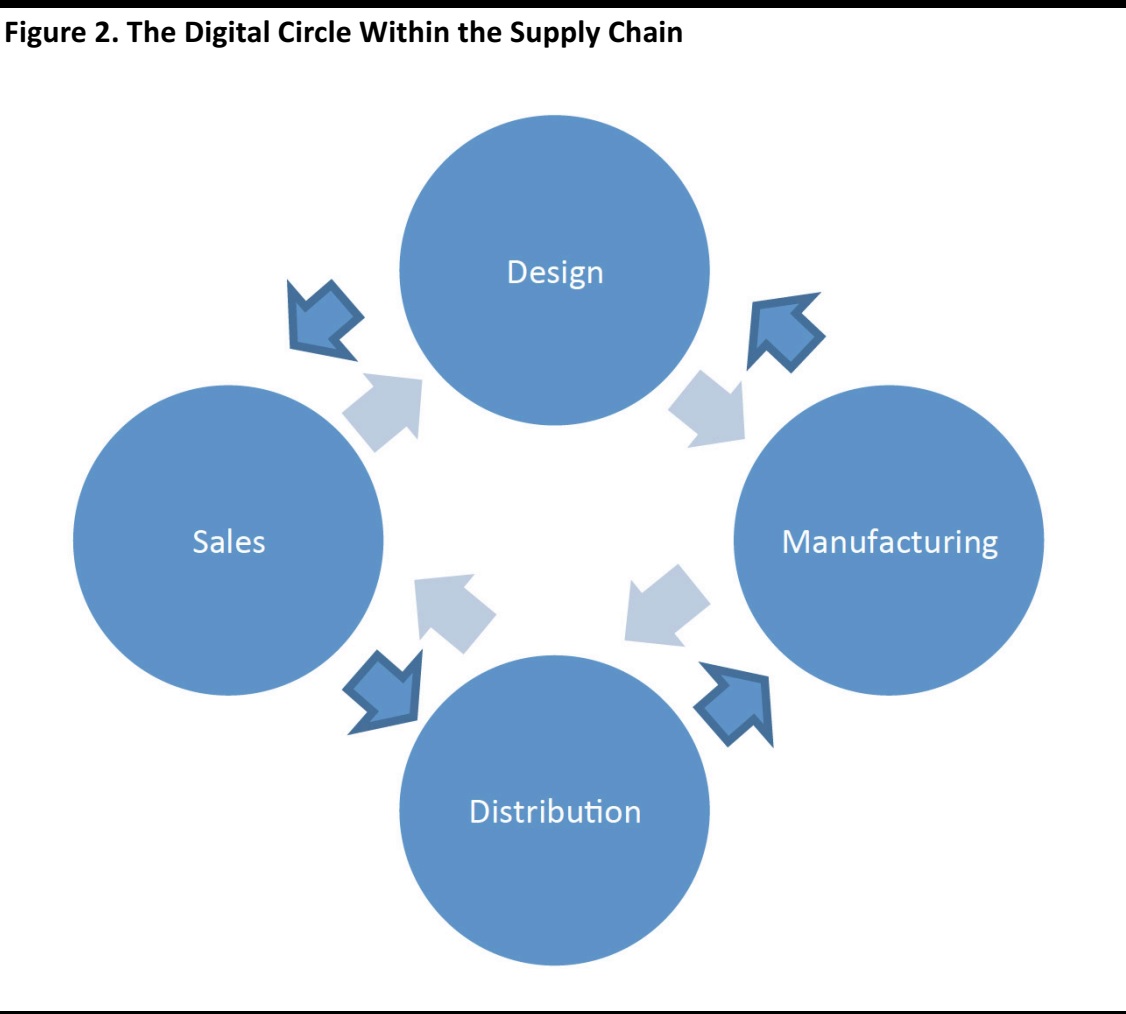

Digital technologies are transforming the apparel supply chain by challenging old operating models and unleashing new opportunities. The apparel supply chain is composed of four main stages—design, manufacturing, distribution and sales—all of which can be radically transformed by digital technology. Digitalization can be applied in the different stages of the supply chain in various ways:

- The design stage can move from a paper-based process to a fully digital process through the use of 3D fashion design software. Such a shift would minimize the need for designers to ship physical samples to producers and reduce the length of time needed to move an item from design to manufacturing.

- In the production stage, manufacturers can employ machinery that uses digital technology to increase precision and efficiency.

- In the distribution stage, companies can use Internet of Things (IoT) and robotics technologies to run smoother picking and packing operations and coordinate delivery of items.

- In the sales stage, retailers can use in-store technology such as sensor systems to track and analyze consumers’ behavior in order to improve sales conversion rates.

The digital transformation of the supply chain helps improve efficiency at each stage, resulting in a leaner process overall. Digitalization provides several operational advantages, including increased speed, flexibility and trust, and better use of resources. The application of digital technologies has the potential to reduce the time it takes to move an item through the supply chain by 48%, according to industry experts at sourcing giant Li & Fung, a sister company of Fung Global Retail & Technology.

However, given the interconnected nature of the supply chain, in order to maximize the benefit that digitalization brings, companies must ensure that the various phases of the supply chain work in synergy.

This report is the first in a series of reports that will investigate the different aspects of the digitalization of the supply chain. As the introduction to the series, this report provides an overview of how the apparel supply chain can be transformed digitally and the advantages that digitalization brings to the value chain. The report analyzes the four main stages of the apparel supply chain and illustrates how digital technology can be applied to each stage.

INTRODUCTION

In apparel, as in many other industries, the supply chain is currently undergoing a digital transformation thanks to the rise of new technologies. Across sectors, digitalization is challenging old operating models and unleashing new potential.

The traditional apparel supply chain consists of four different stages that often operate in silos. But to maximize the benefits of digitalization, the different phases must be well connected and well coordinated, so that any increased efficiency gained at one stage can be reflected in smoother operations in the following stage. Digitalization itself can improve coordination by facilitating communication between different stakeholders along the supply chain.

This report is the first in a series that will investigate the different aspects of the digitalization of the supply chain. It provides an overview of how the apparel supply chain can be transformed digitally and the advantages that digitalization brings to the value chain. The report analyzes the various stages of the apparel supply chain—design, manufacturing, distribution and sales—and illustrates how digital technology can be applied to each stage.

A HOLISTIC DIGITAL SUPPLY CHAIN

A digital supply chain integrates and connects the stakeholders involved in the different stages of the process through digital technology. A number of digital technologies can be applied to the various stages of the apparel supply chain, as summarized below.

Source: Fung Global Retail & Technology

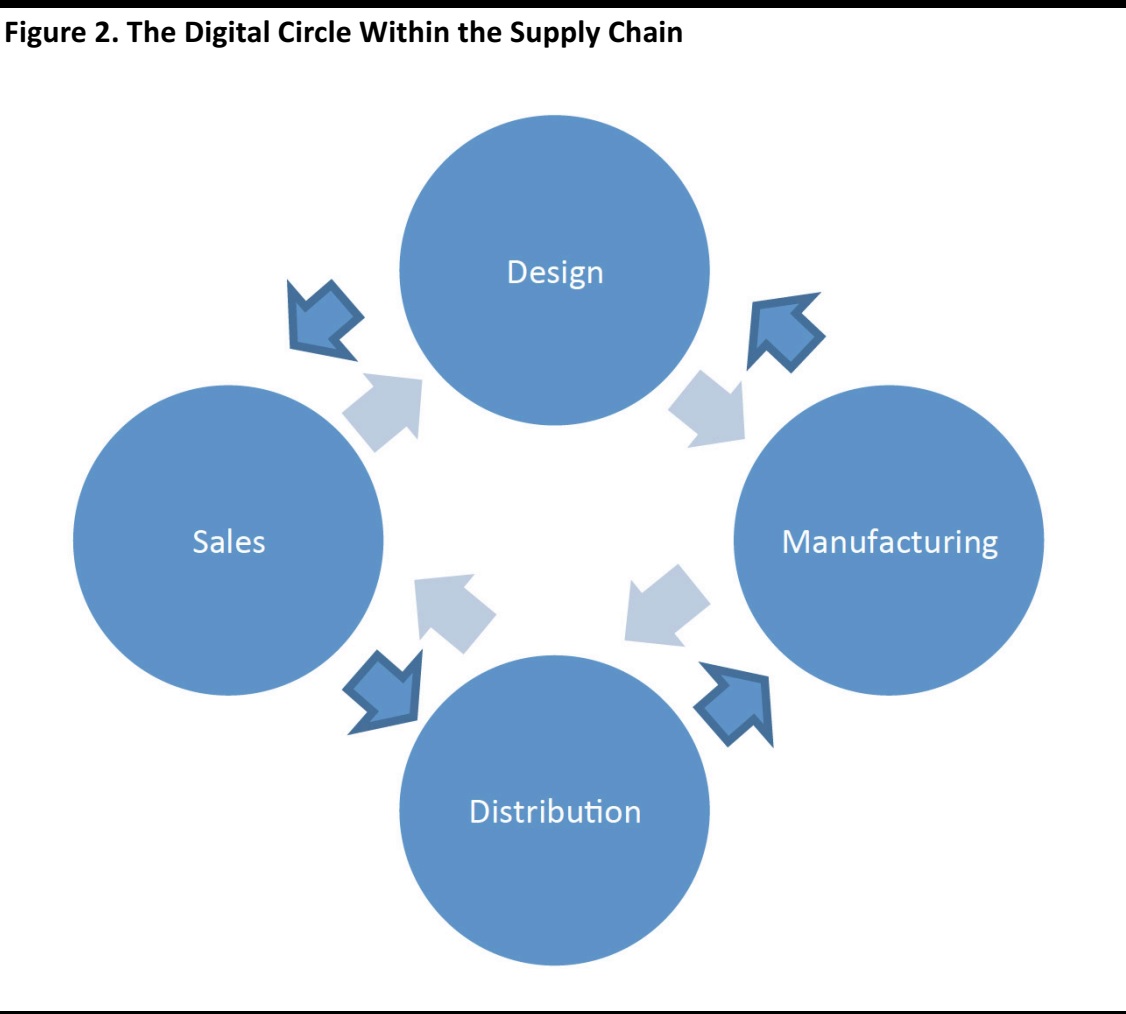

To reap the maximum benefits of digitalization, the digital transformation must involve the value chain as a whole, not just some of its parts. The stages of the supply chain are highly reliant on each other, so a problem at one stage will inevitably have negative consequences on the rest of the chain.

Similarly, the increased efficiency brought by the digitalization of one stage of the supply chain will not improve the overall operation significantly if there is not sufficient coordination with the other stages. Digitalization itself can support coordination within the value chain by facilitating communication between different stakeholders. For example, store managers can use in-store sensors to track inventory levels in real time and to process orders more swiftly.

An integrated digitalized supply chain enables stakeholders to run through the process in both directions:

- Forward from design to sales: Digitalization can improve the efficiency of design, production and distribution and enable stakeholders to respond appropriately, and more quickly, when adjustments are needed. For example, the use of virtual samples allows designers and producers to interact more quickly and efficiently when samples need to be amended.

- Backward from sales to design: Digitalization enables consumers and retailers to trace back what happens in the supply chain, and to see where a product comes from. It provides clarity on whether a product is sustainably or ethically sourced, and helps retailers and shoppers avoid counterfeit products.

This can create a virtuous circle that further enhances the synergies among the different parts of the value chain.

Source: Fung Global Retail & Technology

A LEANER AND FASTER DIGITAL PROCESS

Digitalization helps to create a leaner process at each stage of the supply chain and between stages. A digital supply chain can bring significant advantages, including:

- Speed: Digitalization can help cut product development time significantly. For example, headquarters and suppliers can send digital samples back and forth rather than shipping physical prototypes, thereby saving time.

- Flexibility: Digitalization improves communication among the stakeholders in the different stages of the supply chain and speeds up processes, giving stakeholders more flexibility to adjust quickly to changing consumer demands.

- Risk minimization: Manufacturers can use digital technologies to respond to possible manufacturing issues much more rapidly and efficiently. Since any needed changes can be done virtually, no physical adjustment of the blueprint is needed.

- Trust: Automating interactions with suppliers builds trust. For example, digitalizing payments makes it easier for stakeholders to pay on time, and storing invoice payments digitally in the cloud makes it easier to trace transactions.

- Improved efficiency: Digitalization smooths the interactions between the different stages of the supply chain, making supply chain management more time and resource efficient, which results in reduced operating costs.

- Environmental sustainability: Digital sampling and 3D printing can negate the need to ship physical items up and down the supply chain, which helps designers and manufacturers reduce their use of resources such as materials and fuel.

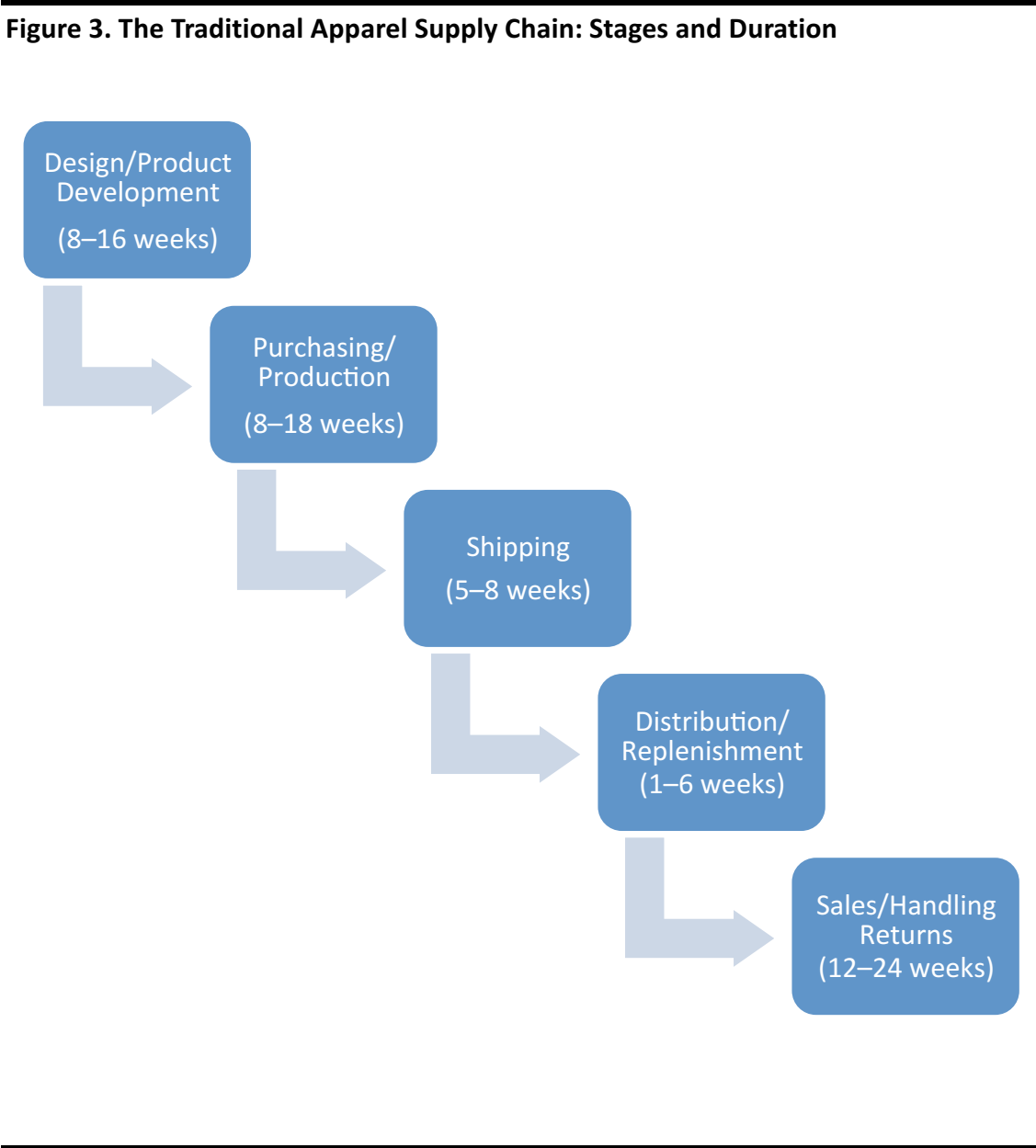

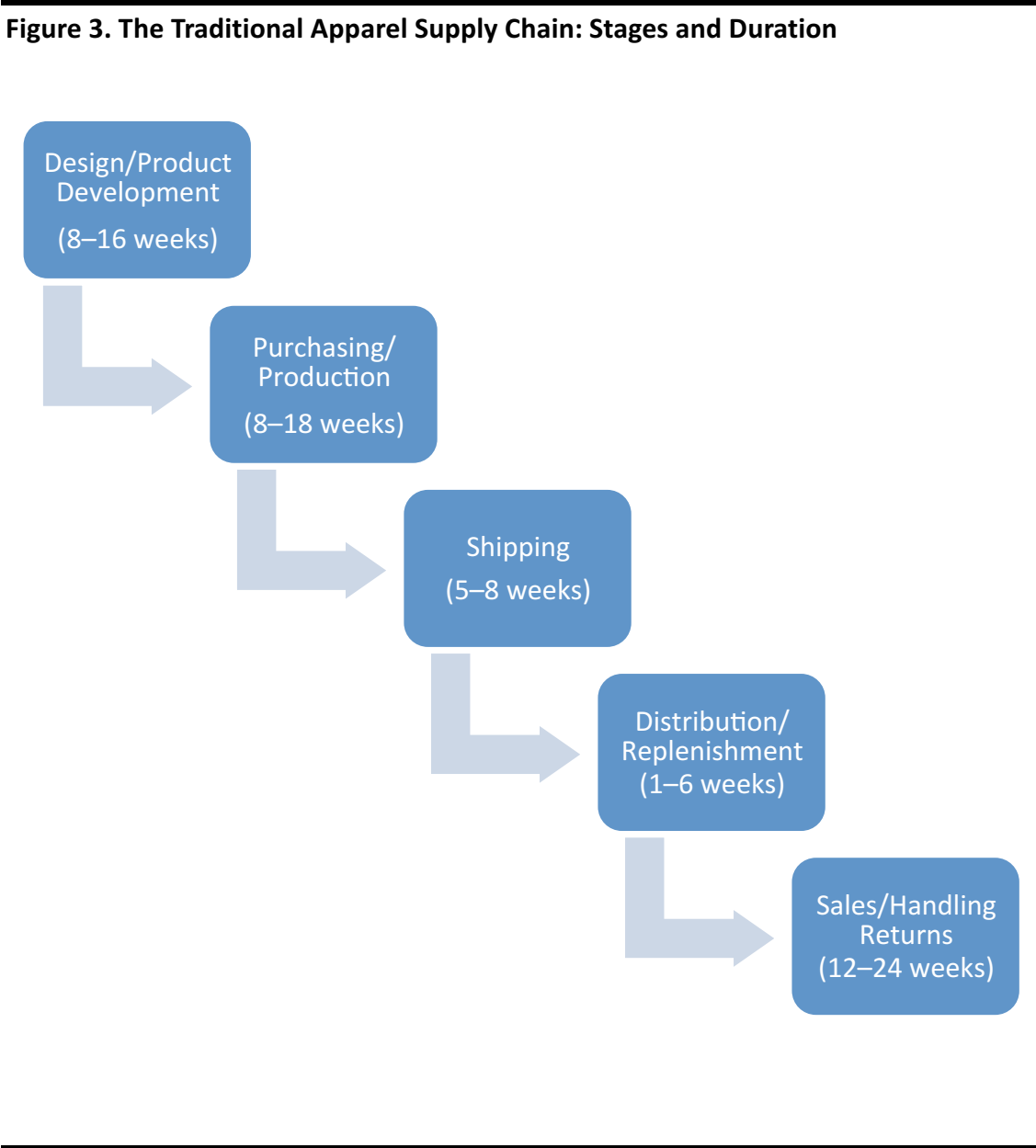

The graphic below shows the stages and typical length of time needed for each stage in a traditional apparel supply chain (note that many of these stages can overlap). It could take about 40 weeks for an apparel line to go through the supply chain from design to sales. Digitalization has the potential to reduce that time by 48%, according to industry experts at Li & Fung.

That means digitalization could cut up to 19 weeks off the process. Shortening the length of time it takes to move an item from design to store is crucial in apparel because fashion items tend to be very time-sensitive and retailers need to respond quickly to changes in consumer preference. (Our report

Speed to Market in Fashion explores the topic in more depth.)

The figure refers to a traditional, non-fast-fashion apparel supply chain with production in China and an end market in the US or Europe. Stages tend to overlap. The duration of the stages can vary substantially in different companies.

Source: Fung Global Retail & Technology

HOW TO DIGITALLY TRANSFORM THE APPAREL SUPPLY CHAIN

Product design and development can move from a paper-based process to a fully digital one. Aspects of production and purchasing can also be digitalized, for example, with the use of IoT technology. In this section, we examine in more detail how the stages of the apparel supply chain can be digitalized.

Product Design and Development: 3D Simulation Saves Time and Money

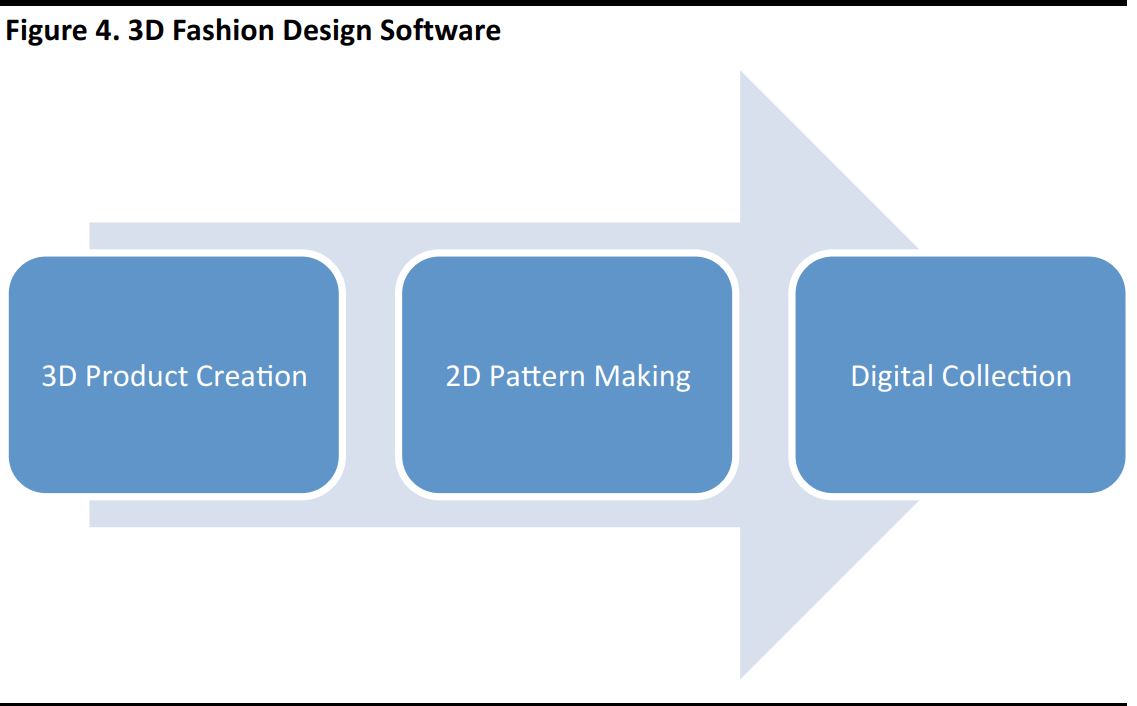

In the product design and development stage of the supply chain, digitalization allows designers to have all the information they need in one place and enables them to design an item virtually using software. All the patterns available to designers can be collected and easily accessed in a database of fabrics, which can also house information such as testing results of the materials.

3D software can be used in digital design to simulate how a garment would behave while worn on the body, while 3D simulation reduces the time and cost associated with creating multiple iterations of a sample garment. 3D design and communication technologies can also reduce travel expenses and the number of prototypes and samples used in the process, while minimizing fabric waste and saving time. Time is crucial for apparel manufacturers and retailers, given the general move toward fast fashion in retail.

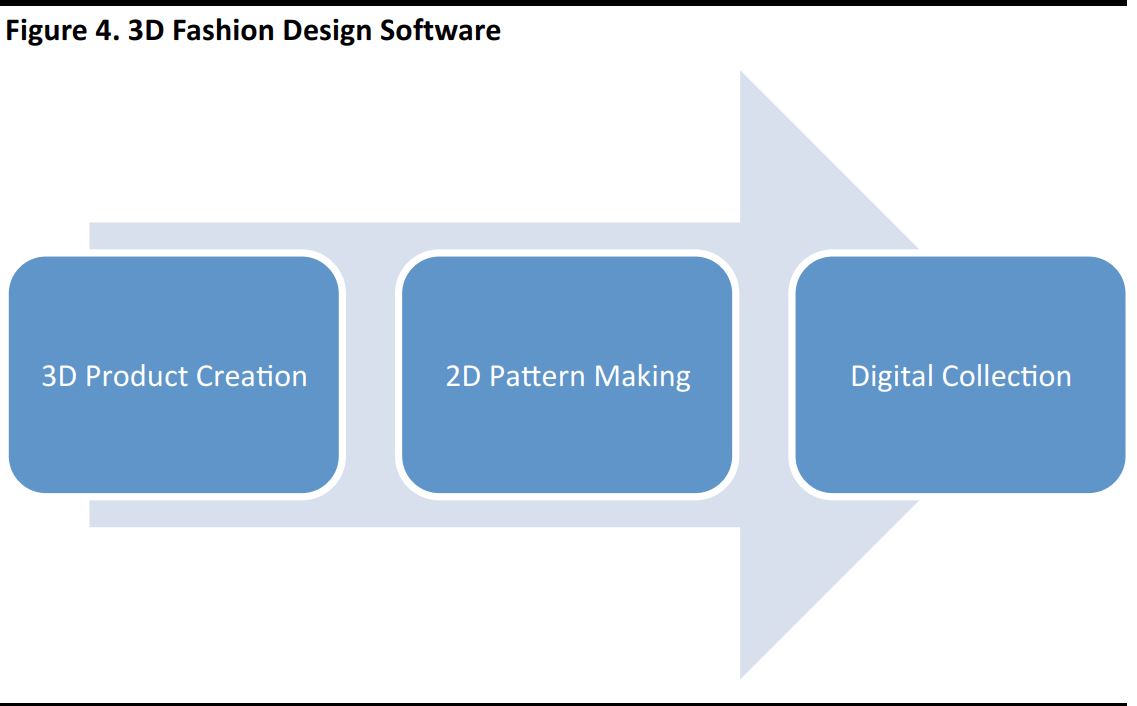

Examples of 3D fashion design software include Marvelous Designer, Optitex and Browzwear, which feature 3D clothing simulation for garment designing. The graphic below illustrates how 3D fashion design software works:

- 3D product creation includes the simulation and fitting of samples on virtual avatars. Designers can create databases of fabrics and sample textures, and customize a season’s style to promptly meet consumer trends and demand.

- Digital pattern making enables designers to draft and adjust pattern sizing quickly and easily through digital processes that eliminate hundreds of manual steps.

- Digital collection software enables users to produce a virtual collection that can be viewed in 3D through photorealistic rendering. Viewers can zoom in and out, and the collection can be shared with various stakeholders, such as suppliers, product developers, merchandisers, and marketing and sales teams.

Source: Optitex

3D printing is another technology that can be used in a digital supply chain. Essentially, a 3D printer is a machine that can produce physical items from digital design files. 3D printing could potentially eliminate all the stages in manufacturing. However, the technology is still limited by the range of materials that can be used, so 3D printing is currently confined to the design/sampling stage of the supply chain. We analyze 3D printing technology in more detail in our report

Enter Design, Exit Sweater: 3D Printing in the Fashion Industry.

Production: Digital Technology Increases Precision and Efficiency

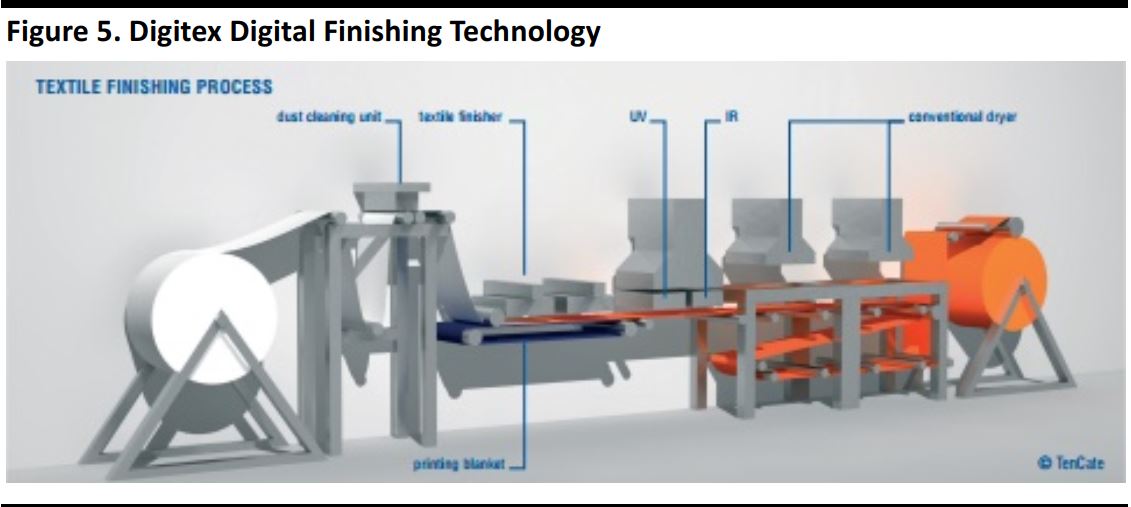

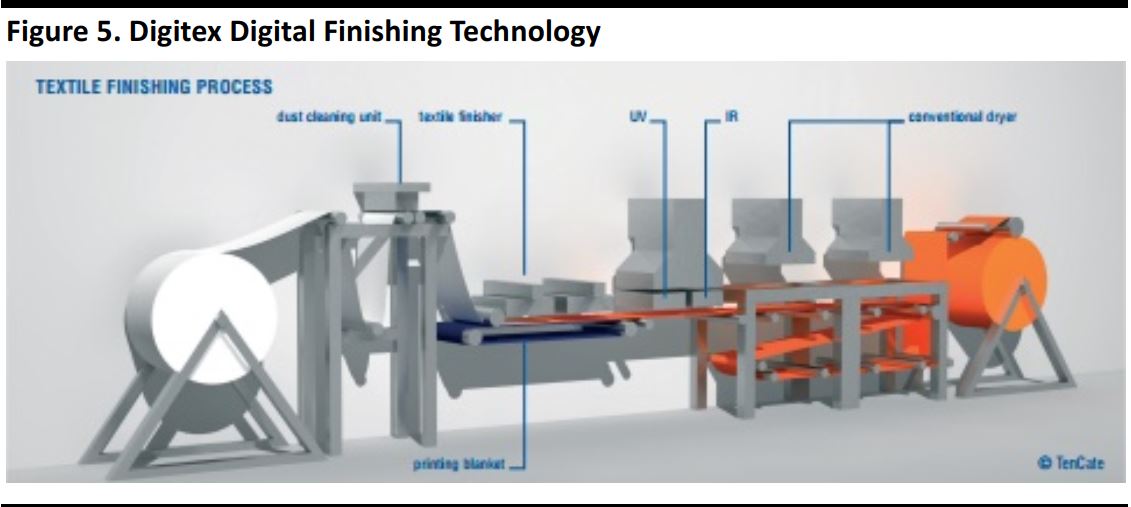

Digitalization is very important in the production stage of a resource-intensive industry such as apparel. An example of digitalization in apparel production is illustrated by Digitex. In a bid to apply digital technology to apparel production in order to improve efficiency and sustainability, a consortium of 28 European organizations representing the apparel industry launched the Digitex initiative to develop digital finishing technology, which applies digital and inkjet technology to apparel manufacturing. The Digitex project was completed in 2010.

Source: Digitex

Source: Digitex

Digital finishing applies digital technology to different phases of the production stage, including printing, coating and dyeing. This dramatically improves the efficiency of resource usage and the precision and quality of the manufacturing process. The technology developed by Digitex enables the production of smart textiles and fabrics that employ nanotechnology, which cannot be produced with traditional manufacturing machinery. Digital finishing technology can be integrated with sensors that monitor the resources used and the waste produced during manufacturing and it can connect production facilities with each other, enabling a more rapid response when adjustments are needed.

Distribution: Smoother Operations Thanks to Automation

IoT technology can be used in distribution. For example, RFID and NFC tags can be used to track inventory and product movements within the supply chain. By enabling the accurate tracking of goods, RFID can support the logistics of multichannel models: services such as reserve-and-collect and click-and-collect rely on having a clear view of inventory, which RFID can provide.

US-based package delivery company United Parcel Service (UPS) provides an example of how logistics can be digitalized in order to improve operational efficiency. UPS drivers carry handheld computers equipped with built-in global positioning system (GPS) chips that enable managers to give the drivers real-time instructions. UPS also developed an app that enables customers to manage their parcel delivery. For example, customers can use the app to change or update their previous package delivery instructions.

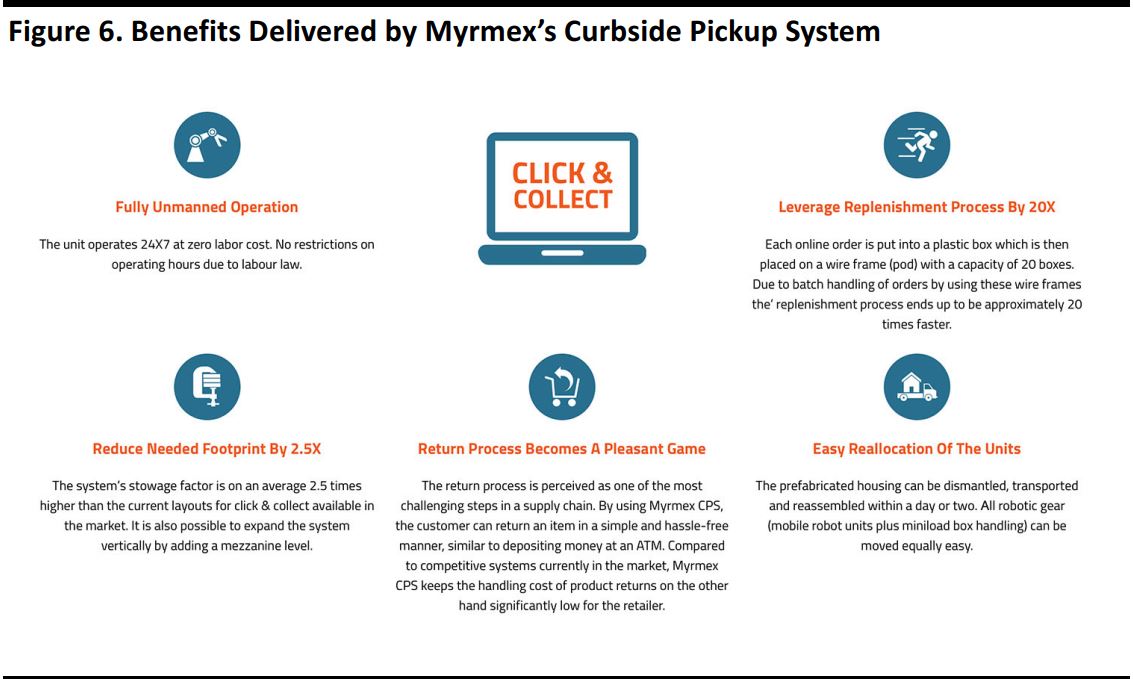

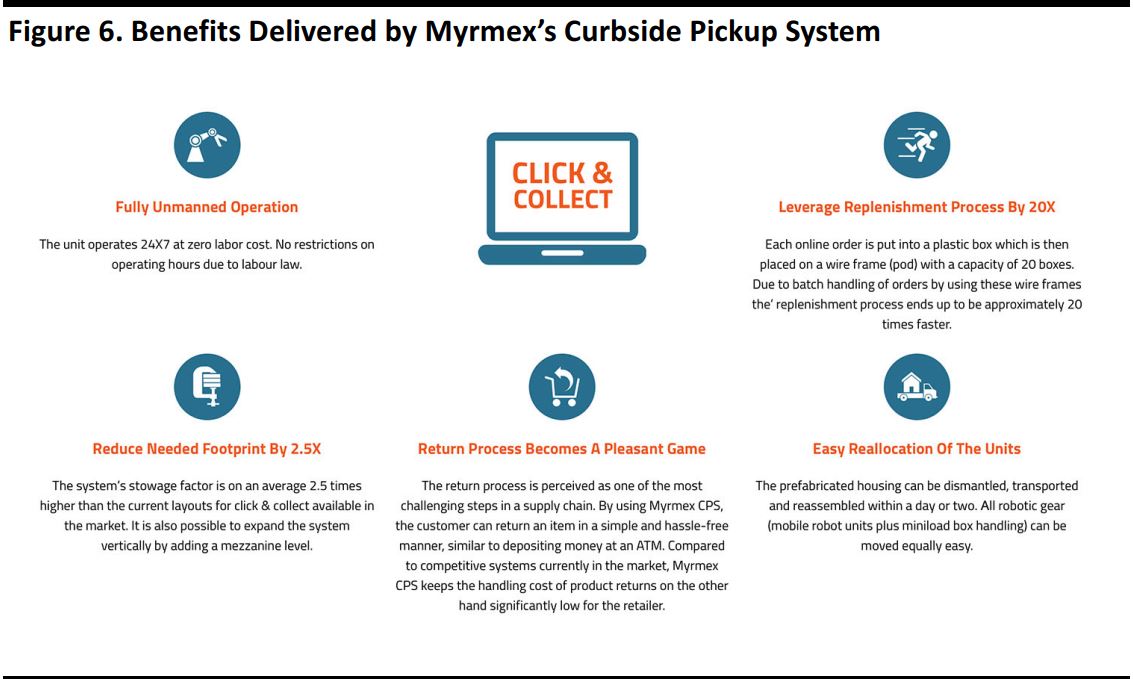

Myrmex, a California-based tech company we met at London Tech Week 2016, provides a further example of digitalization of the distribution stage. The company’s Curbside Pickup System consists of connected robots and autonomous vehicles that minimize operational friction in logistics. The system is conceived to improve the logistics of very time-sensitive items such as perishable food, but it can be used by companies in other industries where timing is important—including apparel—to make delivery more efficient.

The system combines a fully automated loading system and an innovative click-and-collect terminal. Online order loading is fully automated through a system of robotic gear that handles the goods. This lowers costs and minimizes errors, making operations faster and more efficient. The robotic gear places the orders in the right sequence in which they need to be delivered.

Source: Myrmex-inc.com

Smart packaging is another digital solution that can be used in distribution. Such packaging has embedded tags and codes that contain information such as product provenance or messages to customers or logistics managers. The technology can be used to track packages throughout the supply chain and to prevent counterfeiting.

Sales: In-Store Technology Helps to Increase Sales Conversion

In the sales stage of the supply chain, digitalization can take the form of in-store technology, e-commerce, m-commerce and social media. Companies can use social media to interact with customers, promote and sell products and services, provide after-sales services and assistance, and manage returns. Geolocation and inventory-tracking technologies can also be used to expedite the processing of returns. For example, retailers can use these technologies to track items that are returned to a store and then sent to a distribution center.

We have covered how digital technology is applied in-store in a number of reports. In our 2016 report

Letting Online Apparel Shoppers Try Before They Buy: New Multichannel Models, we highlighted a number of examples of digitalization in the sales stage of the supply chain, including:

- Lincherie: This lingerie retailer uses 3D mirrors in its stockless stores to help shoppers identify the right size before they place an online order.

- Bonobos: At this retailer’s stock-free stores, customers can try pieces of the collection on before shopping online.

- com: This tech company places a “Try” button on retailers’ portals. When a shopper clicks the button, Try.com places the order with the retailer, so the shopper pays nothing up front. The retailer ships the item to the shopper, who can then physically try it on before deciding to keep it or return it. Try.com charges the customer for whatever he or she decides to keep.

- Sears’ Reserve It: This service allows customers to reserve items online and try them on in-store before purchasing them.

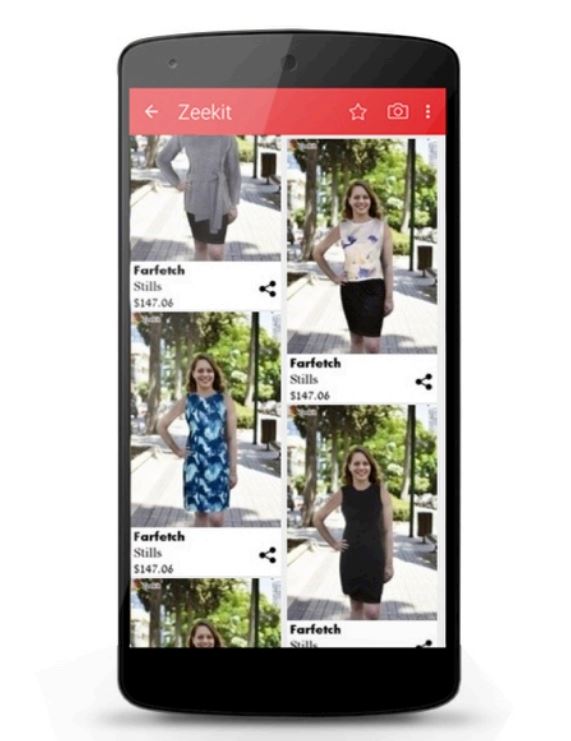

- Zeekit: This app allows shoppers to upload a full-body picture and then virtually try on an item by overlapping the photo with a photo of a selected garment, to see how the garment would look and fit their own body.

Source: Zeekit.co

These solutions help retailers minimize shipping and reduce in-store inventories by making it easier for customers to identify the right size of an item without having to try on different sizes in a store.

Smartrac, a Dutch tech company, provides a retail store optimization system that uses sensors to track store data, which are then gathered in the cloud in order to provide the same level of analytics available in an e-commerce environment to executives and employees. Smartrac’s solution can gather key performance indicators that can be used to help managers improve sales conversion rates. For example, the system can track:

- How long it takes to replenish the sales floor.

- How long it takes to stock an item that is received.

- How many items are misplaced in the store.

- The rate of conversion from browsing.

Smartrac’s system can also show store managers what happens when an item is taken to the fitting room and how well employees are engaging with customers. The system provides brick-and-mortar retailers with a wealth of inventory information to improve stock keeping, displays and sales conversion. Li & Fung’s retail tech company, Catalyst, has a new RFID partnership with Smartrac to offer in-store product tracking.

Source: Smartrac-Group.com

Other examples of digitalization in the sales stage of the supply chain include the use of sensors to monitor lighting and temperature in stores in order to use energy more efficiently. Sensors can also be used for manual tasks such as tracking in-store inventory or changing prices via smart tags that can be used to adjust pricing in real time during promotions. This enables sales associates to spend more time interacting with customers and may reduce the need for extra personnel, thereby reducing operational costs.

Digitalization also enables traceability in the supply chain. In the sales phase, it enables customers to trace back the history of the item they are buying. This is important, as consumers are becoming more aware of issues regarding product provenance, environmental sustainability and ethical sourcing.

Blockverify, a London-based tech startup, developed the use of blockchain technology to trace back the journey of an item through the supply chain. The technology assigns a unique code to a product, which can be tracked on a register and monitored at all stages along the value chain. This enables the identification of diverted products, stolen merchandise, fraudulent transactions and counterfeit goods. Such technology has been used to manage the supply chain of high-value items, including pharmaceuticals, luxury goods, diamonds and electronics.

After Sales: Digital Technology Encourages Brand Engagement

Lastly, technology can extend beyond the sale of the product, into the customer-use stage. Notably, NFC technology can be embedded in apparel items to provide customers with a personalized experience and encourage brand engagement:

- Fashion brand Babyghost partnered up with tech firm BitSE to launch a fashion-tech line that embeds NFC technology which enables greater interaction with customers who wear the garments. The NFC tag embedded in the garment sends information about the item to the wearer through an app installed on his or her smartphone; this can include information such as who modelled the item at its launch during fashion shows. The collection was presented at Shanghai Fashion Week in October 2016.

Source: Mybabyghost.com

- Ski and performance-wear brand SPYDER, in collaboration with Li & Fung and SMARTRAC, launched a US Ski Team collection of NFC-enabled gear. The line, unveiled in October 2016, consists of items that can connect with consumer devices thanks to embedded NFC tags. The technology enables users to access location-based information including weather and snow conditions and to interact in real time on social media.

Source: Spyder.com

KEY TAKEAWAYS

Digitalization of the supply chain brings many advantages to apparel retailers and manufacturers. A digital supply chain helps companies run smoother operations, use resources more efficiently, better coordinate the various stages in the product lifecycle, and better respond to unforeseen circumstances and changing consumer trends.

However, given the interconnected nature of the supply chain, in order to take advantage of the opportunities that digitalization brings, companies need to make sure that the digital transformation occurs within and through the different stages of the value chain. This can be achieved through a clever implementation of digital strategies that facilitate communication and coordination among the different stakeholders involved.

This report is the first in a series of reports that will investigate the different aspects of the digitalization of the supply chain. As the introduction to the series, this report provides an overview of how the apparel supply chain can be transformed digitally and the advantages that digitalization brings to the value chain. The report analyzes the four main stages of the apparel supply chain and illustrates how digital technology can be applied to each stage.

This report is the first in a series of reports that will investigate the different aspects of the digitalization of the supply chain. As the introduction to the series, this report provides an overview of how the apparel supply chain can be transformed digitally and the advantages that digitalization brings to the value chain. The report analyzes the four main stages of the apparel supply chain and illustrates how digital technology can be applied to each stage.

The graphic below shows the stages and typical length of time needed for each stage in a traditional apparel supply chain (note that many of these stages can overlap). It could take about 40 weeks for an apparel line to go through the supply chain from design to sales. Digitalization has the potential to reduce that time by 48%, according to industry experts at Li & Fung.

That means digitalization could cut up to 19 weeks off the process. Shortening the length of time it takes to move an item from design to store is crucial in apparel because fashion items tend to be very time-sensitive and retailers need to respond quickly to changes in consumer preference. (Our report Speed to Market in Fashion explores the topic in more depth.)

The graphic below shows the stages and typical length of time needed for each stage in a traditional apparel supply chain (note that many of these stages can overlap). It could take about 40 weeks for an apparel line to go through the supply chain from design to sales. Digitalization has the potential to reduce that time by 48%, according to industry experts at Li & Fung.

That means digitalization could cut up to 19 weeks off the process. Shortening the length of time it takes to move an item from design to store is crucial in apparel because fashion items tend to be very time-sensitive and retailers need to respond quickly to changes in consumer preference. (Our report Speed to Market in Fashion explores the topic in more depth.)

Source: Digitex

Source: Digitex