DIpil Das

In this report, we will look at cleantech in retail: How technology is helping retailers meet rising consumer expectations around sustainability. Cleantech, or clean technology, can support the harnessing of renewable materials and energy sources, a reduction in the use of natural resources, and a reduction or elimination of emissions and waste.

Shifting consumer attitudes

Consumer expectations are shifting: Consumers are paying more attention to how products are made, and purchasing decisions are increasingly influenced by ethical and sustainability factors.

According to a US survey conducted in March 2018 by business applications firm CGS, one of the main factors affecting the consumers purchasing decision included the material/fabric used to make the product and the ethical factors of the product. More than one-third of respondents stated that “where a product is made” would impact the purchasing decision. The survey also found that half of males aged 18-34 and women aged 18-24 and 34-55 consider ethical manufacturing a buying factor. CGS found that 40% of respondents expressed interest in the ethics of products; and half of millennials, 45% of Gen Xers and 40% of baby boomers would pay more for a sustainable product.

According to the Natural Marketing Institute in January 2018, 64% of millennials and 51% of Gen Xers would buy environmentally friendly and sustainable products if they were more available. The Natural Marketing Institute found that millennials are 28% more likely than others to say they will pay more for sustainable and ethically produced products.

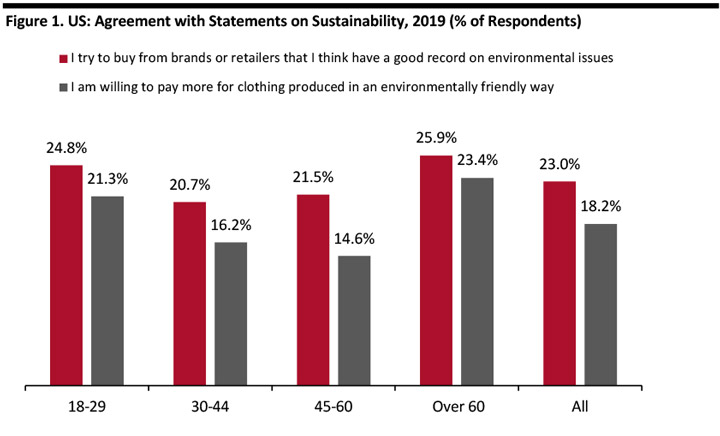

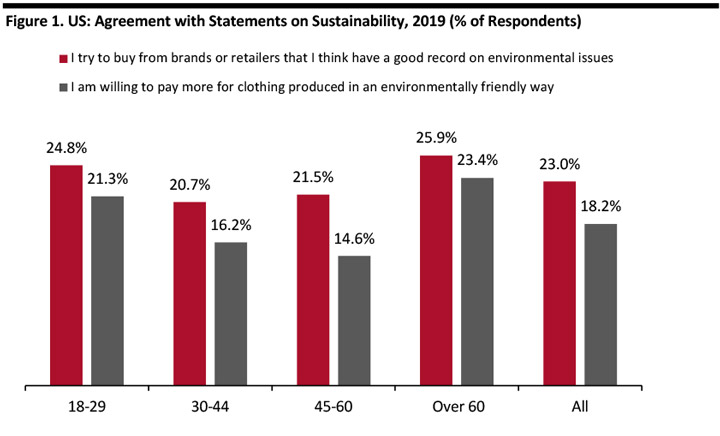

Coresight Research survey data suggest something of a bifurcation in interest in sustainability by age, with demand peaking among the youngest and oldest adult age groups.

[caption id="attachment_90391" align="aligncenter" width="720"] Base: 1,732 US Internet users ages 18+

Base: 1,732 US Internet users ages 18+

Source: Coresight Research[/caption] Raw materials Increasingly, consumers expect brands and retailers to be responsible for products upstream to raw material origin, but knowing this can be a challenge for retailers. According to the Center for Retail Compliance, the two aspects that affect retail the most are the environmental impact of raw materials and the risk of supply chain disruption. Blockchain technology promises to generate the visibility along the supply chain that is now lacking, as it helps companies track products from source to store. Tech company Provenance, a digital platform that allows brands to take the step toward product and supply chain transparency, uses blockchain and a smart labeling system to help retailers track raw materials every step of the way through the production process. Provenance collaborated with London-based designer Martine Jarlgaard to create one of the first tracked garments using blockchain, allowing customers to view the product journey just by scanning the product label. In 2017, Walmart partnered with IBM to create a transparent food tracking system using blockchain. IBM, Walmart and Nasdaq-listed Chinese retailer JD.com, together with the Tsinghua University National Engineering Laboratory for E-Commerce Technologies, announced a Blockchain Food Safety Alliance collaboration to improve food tracking and safety in China. The process includes tracking where the food was grown, handled, stored, inspected and so on. Logistics Logistics is emerging as another key aspect of the sustainability equation. How a retailer imports and distributes merchandise can have a major impact on greenhouse gas emissions. The Retail Industry Leaders Association and Center for Retail Compliance has noted that retail sees various solutions to making logistics and transportation more sustainable. One example is applying data-rich management systems that allow detailed planning to cut the number of trips a vehicle would take, cutting emissions and reducing cost. Management systems can collect data on the transportation chain to improve route planning and load optimization, and retailers can integrate data with logistics and warehouse management to optimize both networks. In a pilot by Macy’s and Schneider National, the companies were able to generate savings of $25,000 per lane and cut greenhouse gas emissions 150 tons. A number of companies are working on making transportation more sustainable: Neste is an oil refining company from Finland and one of the world’s largest producers of diesel refined from waste and residue. Lanzatech is a biotech startup that has identified a bacteria that can turn carbon emissions into ethanol. UK-based CGON has created a hydrogen additive product that cuts emissions up to 80% and delivers fuel savings up to 20%: The system works by introducing a small amount of pure hydrogen directly into a chamber where the fuel-air mixture gets combined with the hydrogen and creates a complete combustion cycle. CGON says most of the waste gases are eliminated Supermarket chain Albertsons said that as part of its sustainability initiative, the company will purchase 10 all-electric Tesla semi-trucks. The trucks can travel from 300-500 miles on one charge and use less than 2 kilowatt hours of energy per mile. Food-delivery firm Deliveroo is one of Britain’s most successful startups since. A large part of Deliveroo’s efficiency is to do with big data and machine learning. Data have been critical in ensuring a successful experience for all customers. Data are used to support decisions using machine learnings. Data are also used to assist in “real-time operational monitoring” – Deliveroo uses real-time data to fix any problems that that may arise. The dispatch engine they use, called Frank, calculates the most efficient combination of riders and customer orders using machine learning algorithms and historical data. Domestic operations According to a report by McKinsey, energy is the fourth-largest in-store operating cost for retailers after labor, rent and marketing. And, stores are an important touch point for customers: Making your stores more environmentally friendly can deliver greater impact as it is something the customer sees, enters and interacts with, making it more tangible than a far-off manufacturing operation. According to a 2014 report by Schneider Electric, approximately 657,000 retail buildings in the US consume $20 billion in energy each year – but went on to say retailers could shave $3 billion off that cost by being more energy efficient. The opportunity for food retailers is even greater: Schneider Electric audits found that average consumption for food retailers was 51.3 kWh per square foot, while for non-food retailers it was just 16.1 kWh per square foot. Solutions to cut energy consumption include optimization of HVAC system controls, installation of variable speed and measurement, monitoring and benchmarking of site energy consumption. To reduce HVAC energy use, retailers can install efficient packaged HVAC unit controls. To reduce lighting energy, retailers can switch to LED lights and low-wattage T8 linear fluorescent fixtures. Packaging and waste Packaging is coming under increased scrutiny from consumers, regulators and environmental groups who are looking for more environmentally friendly designs. According to National Geographic, there are 5.35 trillion pieces of plastic debris in the oceans, totaling 260,000 tons. National Geographic also estimates that 79% of product packaging ends up in landfills, and predicts that by 2050 there will be 12 billion metric tons of plastic in landfills. Three technology trends are prominent in sustainable packaging: Fiber-based materials, smart packaging and 3D printing. Fiber-based materials are an alternative to plastic packaging, using plant-based fibers. Smart packaging consists of specialists such as the STI group which has developed technologies such as concealed radio-frequency identification printed directly on the packaging to make tracking easier. 3D printing lets companies test products and packaging before going into mass production. A company called Smart Cups came out with a range of 3D-printed cups that produce an energy drink when water is added: The ingredients of the drink are integrated into the packaging, so what would otherwise be a very heavy package filled with liquid is instead a lightweight (more sustainably transported) cup. Many consumer goods companies are tackling the plastics challenge. One example is Nestlé, which has said it wants to make its packaging recyclable or reusable by 2025. Nestlé collaborated with PureCycle technologies, which provides recycled polypropylene with properties equal to virgin polymer. The company is working with Nestlé to make food-grade recycled polypropylene from plastic feedstock. Nestlé also started eliminating straws in February 2019 and will use paper packaging for its popular chocolate drink Nesquik in the first half of 2019.

Base: 1,732 US Internet users ages 18+

Base: 1,732 US Internet users ages 18+ Source: Coresight Research[/caption] Raw materials Increasingly, consumers expect brands and retailers to be responsible for products upstream to raw material origin, but knowing this can be a challenge for retailers. According to the Center for Retail Compliance, the two aspects that affect retail the most are the environmental impact of raw materials and the risk of supply chain disruption. Blockchain technology promises to generate the visibility along the supply chain that is now lacking, as it helps companies track products from source to store. Tech company Provenance, a digital platform that allows brands to take the step toward product and supply chain transparency, uses blockchain and a smart labeling system to help retailers track raw materials every step of the way through the production process. Provenance collaborated with London-based designer Martine Jarlgaard to create one of the first tracked garments using blockchain, allowing customers to view the product journey just by scanning the product label. In 2017, Walmart partnered with IBM to create a transparent food tracking system using blockchain. IBM, Walmart and Nasdaq-listed Chinese retailer JD.com, together with the Tsinghua University National Engineering Laboratory for E-Commerce Technologies, announced a Blockchain Food Safety Alliance collaboration to improve food tracking and safety in China. The process includes tracking where the food was grown, handled, stored, inspected and so on. Logistics Logistics is emerging as another key aspect of the sustainability equation. How a retailer imports and distributes merchandise can have a major impact on greenhouse gas emissions. The Retail Industry Leaders Association and Center for Retail Compliance has noted that retail sees various solutions to making logistics and transportation more sustainable. One example is applying data-rich management systems that allow detailed planning to cut the number of trips a vehicle would take, cutting emissions and reducing cost. Management systems can collect data on the transportation chain to improve route planning and load optimization, and retailers can integrate data with logistics and warehouse management to optimize both networks. In a pilot by Macy’s and Schneider National, the companies were able to generate savings of $25,000 per lane and cut greenhouse gas emissions 150 tons. A number of companies are working on making transportation more sustainable: Neste is an oil refining company from Finland and one of the world’s largest producers of diesel refined from waste and residue. Lanzatech is a biotech startup that has identified a bacteria that can turn carbon emissions into ethanol. UK-based CGON has created a hydrogen additive product that cuts emissions up to 80% and delivers fuel savings up to 20%: The system works by introducing a small amount of pure hydrogen directly into a chamber where the fuel-air mixture gets combined with the hydrogen and creates a complete combustion cycle. CGON says most of the waste gases are eliminated Supermarket chain Albertsons said that as part of its sustainability initiative, the company will purchase 10 all-electric Tesla semi-trucks. The trucks can travel from 300-500 miles on one charge and use less than 2 kilowatt hours of energy per mile. Food-delivery firm Deliveroo is one of Britain’s most successful startups since. A large part of Deliveroo’s efficiency is to do with big data and machine learning. Data have been critical in ensuring a successful experience for all customers. Data are used to support decisions using machine learnings. Data are also used to assist in “real-time operational monitoring” – Deliveroo uses real-time data to fix any problems that that may arise. The dispatch engine they use, called Frank, calculates the most efficient combination of riders and customer orders using machine learning algorithms and historical data. Domestic operations According to a report by McKinsey, energy is the fourth-largest in-store operating cost for retailers after labor, rent and marketing. And, stores are an important touch point for customers: Making your stores more environmentally friendly can deliver greater impact as it is something the customer sees, enters and interacts with, making it more tangible than a far-off manufacturing operation. According to a 2014 report by Schneider Electric, approximately 657,000 retail buildings in the US consume $20 billion in energy each year – but went on to say retailers could shave $3 billion off that cost by being more energy efficient. The opportunity for food retailers is even greater: Schneider Electric audits found that average consumption for food retailers was 51.3 kWh per square foot, while for non-food retailers it was just 16.1 kWh per square foot. Solutions to cut energy consumption include optimization of HVAC system controls, installation of variable speed and measurement, monitoring and benchmarking of site energy consumption. To reduce HVAC energy use, retailers can install efficient packaged HVAC unit controls. To reduce lighting energy, retailers can switch to LED lights and low-wattage T8 linear fluorescent fixtures. Packaging and waste Packaging is coming under increased scrutiny from consumers, regulators and environmental groups who are looking for more environmentally friendly designs. According to National Geographic, there are 5.35 trillion pieces of plastic debris in the oceans, totaling 260,000 tons. National Geographic also estimates that 79% of product packaging ends up in landfills, and predicts that by 2050 there will be 12 billion metric tons of plastic in landfills. Three technology trends are prominent in sustainable packaging: Fiber-based materials, smart packaging and 3D printing. Fiber-based materials are an alternative to plastic packaging, using plant-based fibers. Smart packaging consists of specialists such as the STI group which has developed technologies such as concealed radio-frequency identification printed directly on the packaging to make tracking easier. 3D printing lets companies test products and packaging before going into mass production. A company called Smart Cups came out with a range of 3D-printed cups that produce an energy drink when water is added: The ingredients of the drink are integrated into the packaging, so what would otherwise be a very heavy package filled with liquid is instead a lightweight (more sustainably transported) cup. Many consumer goods companies are tackling the plastics challenge. One example is Nestlé, which has said it wants to make its packaging recyclable or reusable by 2025. Nestlé collaborated with PureCycle technologies, which provides recycled polypropylene with properties equal to virgin polymer. The company is working with Nestlé to make food-grade recycled polypropylene from plastic feedstock. Nestlé also started eliminating straws in February 2019 and will use paper packaging for its popular chocolate drink Nesquik in the first half of 2019.