DIpil Das

Introduction

What’s the Story? Sourcing journeys involve multidirectional flows of data between various parties. Much of this data tends to be recorded manually or documented on paper and transferred to a data analysis software, and typically housed in data silos for specific business units. During these processes, valuable data could be lost, misrepresented or have errors incorporated, preventing companies from unlocking the full potential of their sourcing strategies. Artificial intelligence (AI) mimics human intelligence—it can identify patterns and analyze multiple levels of data simultaneously, enabling faster and more intelligent data processing. As such, AI programs can be developed to make business processes and operations more efficient. In this report, we discuss five key applications of AI across sourcing stages, the challenges they address and innovators offering AI-based solutions with retail applications. We define sourcing as the activities involving supplier and vendor search, supplier evaluation, supplier selection and order placement, production monitoring, shipping to retailers’ and brands’ destination markets, and receipt of goods by buyer brand or retailers. Why It Matters Sourcing procedures and practices are facing increasing scrutiny, largely due to:- Continuing uncertainty amid the pandemic and unforeseen global events

- Deeper visibility into unethical practices adopted by factories, which pose a greater reputational risk to companies now more than ever given the ubiquity of media outlets and increased awareness among consumers of environmental sustainability and social equity

- Increased costs incurred due to disruptions to the global supply chain and forced diversification

- Demand for increased speed for speed to market, requiring challenges including suppliers’ locations and errors in manual data collection and maintenance to be overcome

- Widening gap between retailing and sourcing due to faster adoption of technologies at the “front end” of the retail supply chain—comprising inventory management, in stores and online, and at the last-mile delivery stage

AI in Sourcing: Coresight Research Analysis

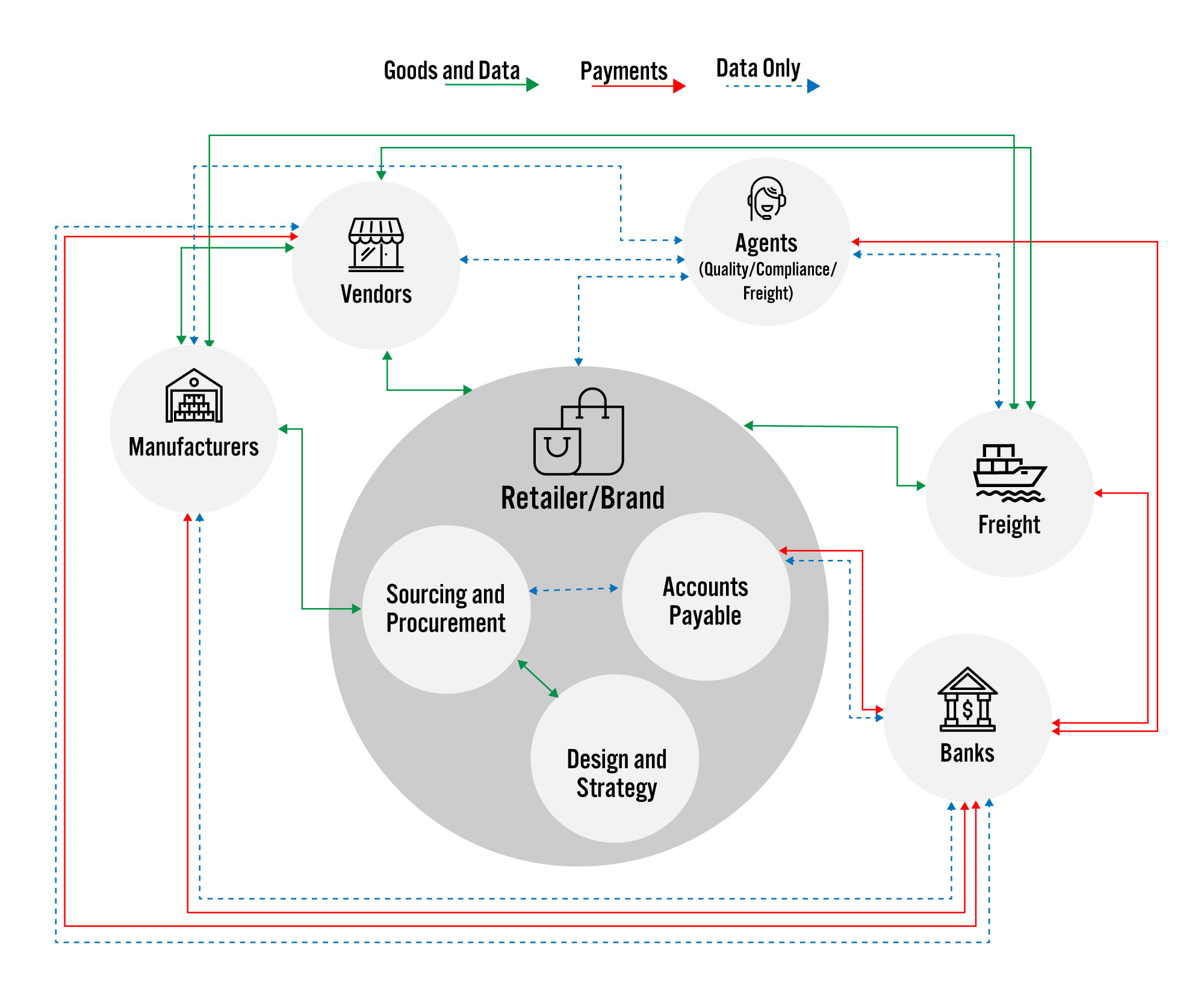

Brands and retailers tend to work with a number of manufacturers, vendors and agents for their sourcing and procurement needs, equating to hundreds of suppliers spread across many geographies, each with varying degrees of scale, compliance and quality. Information and data moving between each of the parties and being captured in siloes tend to vary, as companies use different systems and software. This poses difficulties for sourcing and procurement teams in linking up and accessing data they need to act on. AI applications can help alleviate these challenges and make sourcing more efficient.Figure 1. Flow of Data, Goods and Payments Between Stakeholders Involved in Sourcing [caption id="attachment_148388" align="aligncenter" width="700"]

Source: Coresight Research[/caption]

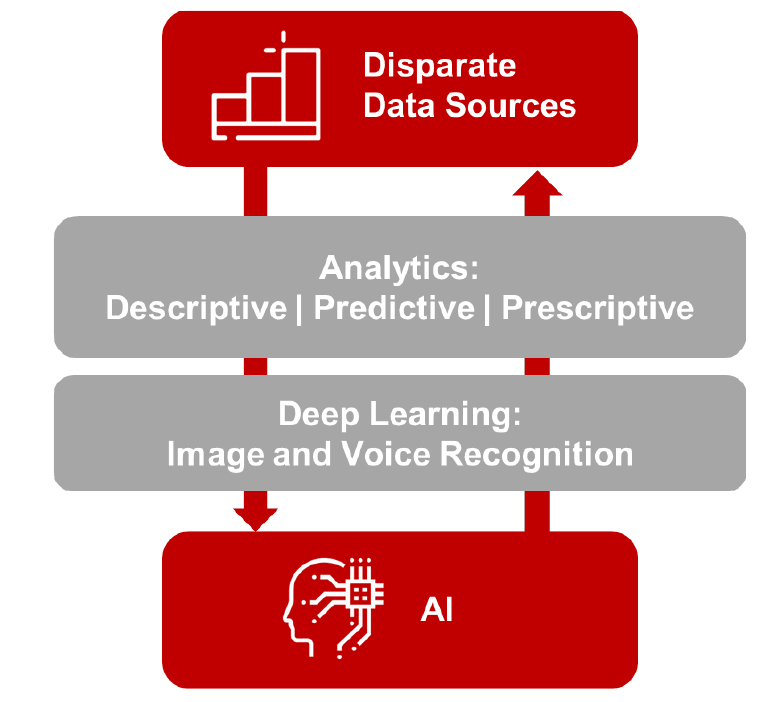

The strengths of AI and ML technology include its ability to detect patterns and discover relationships between disparate data sources—making both useful in leveraging isolated data, as illustrated in Figure 3. AI connects disparate data sources to generate analytics and interpret words, voices and images.

Source: Coresight Research[/caption]

The strengths of AI and ML technology include its ability to detect patterns and discover relationships between disparate data sources—making both useful in leveraging isolated data, as illustrated in Figure 3. AI connects disparate data sources to generate analytics and interpret words, voices and images.

Figure 2. How AI Finds Relationships Among Data [caption id="attachment_148389" align="aligncenter" width="700"]

Source: Coresight Research[/caption]

AI’s ability to draw insights from distinct data sets enables sourcing teams to answer several questions that can help formulate their sourcing strategy, such as:

Source: Coresight Research[/caption]

AI’s ability to draw insights from distinct data sets enables sourcing teams to answer several questions that can help formulate their sourcing strategy, such as:

- Who needs what and when?

- How much will be spent?

- Which are the ideal suppliers?

- What are the costs and benefits of working with each supplier?

- How often do we buy?

- Where and when will the goods be delivered?

- Challenges: Identifying the right set of suppliers that can deliver—this gets further complicated for multicategory brands and retailers, and when sourcing from multiple suppliers for each product category.

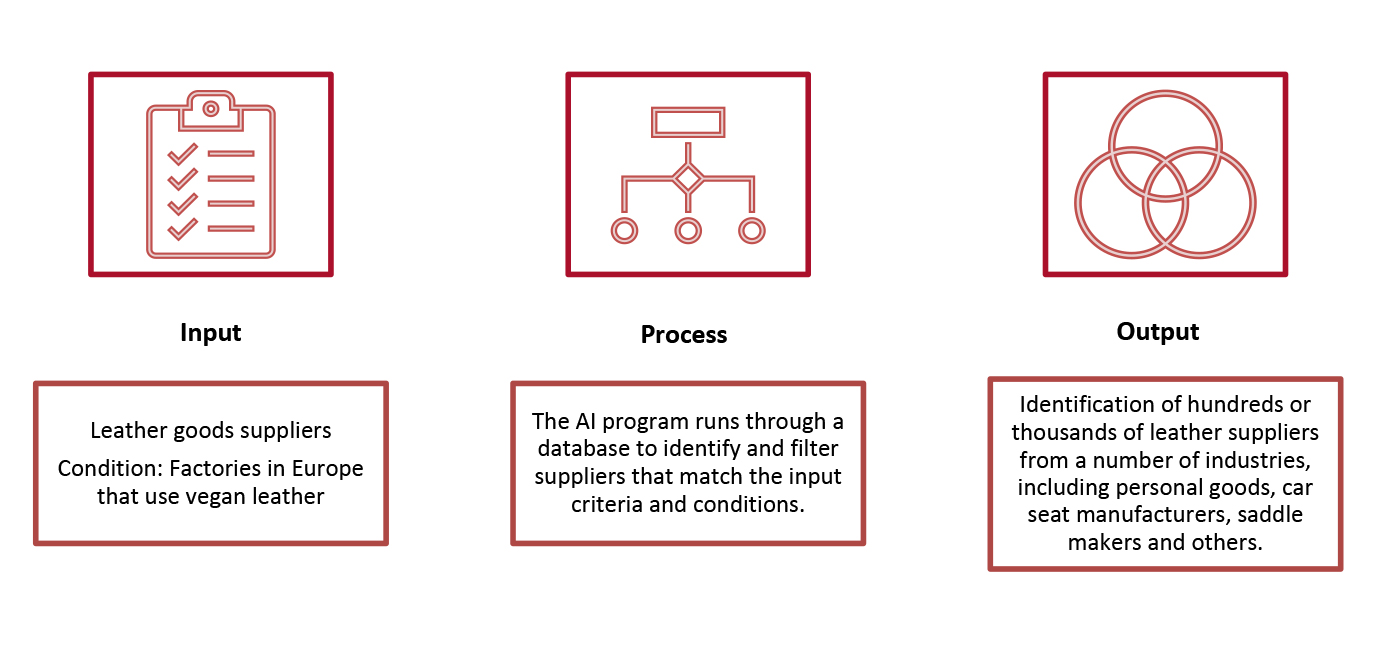

- AI application: Smart supplier search involves combining sourcing expertise with an AI-powered tool to enhance supplier identification. The technology can almost instantly skim through millions of suppliers and provide recommendations based on search criteria defined by the sourcing specialist. If the tool uses natural language processing (NLP), the specialist can enter the search criteria using plain language. With each iteration of terms input by the specialist, the NLP tool builds out its database further and gets trained to learn and deliver better results. A typical human search may look for suppliers in a familiar environment or industry, such as leather goods in retail, but an AI tool can search for suppliers in other industries that can provide the same or similar products or raw materials. Moreover, a manual search for vegan leather suppliers in a paper-based index, for example, will only be possible if the user uses the term “vegan”. In an AI-based system, vegan leather suppliers can be tagged with alternate terms, such as “non-animal” or “plant-based,” to deliver a wider range of search results.

Figure 3. AI Tool Using NLP To Narrow Down Suppliers Based on Human Inputs [caption id="attachment_148390" align="aligncenter" width="699"]

Source: Coresight Research[/caption]

Source: Coresight Research[/caption]

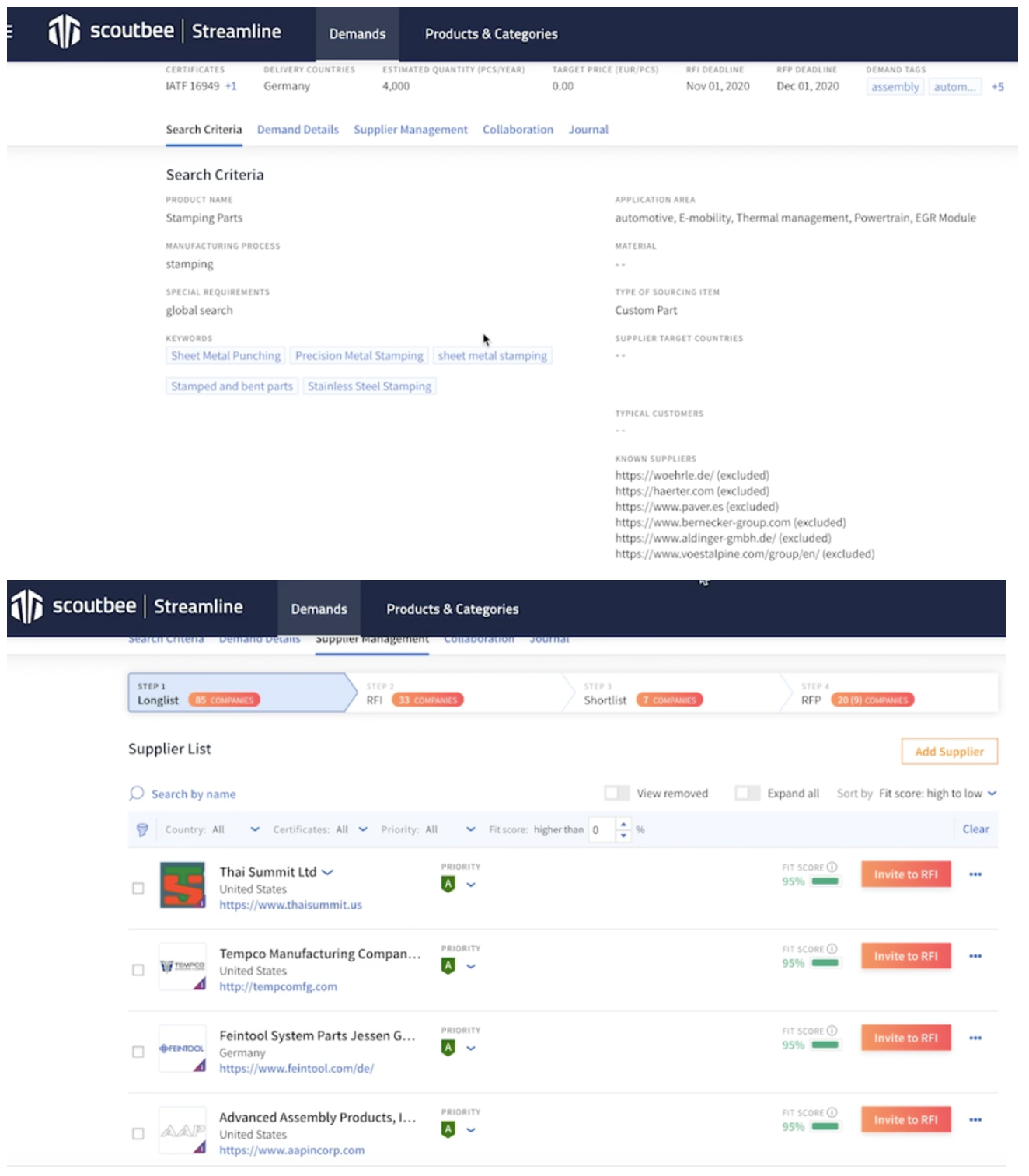

- Innovator: Founded in 2015, Scoutbee is an AI-driven supplier discovery platform that helps identify suppliers within days, rather than weeks or months (the typical timeline when performing a search unaided by AI). Users define their search criteria in the Scoutbee platform by providing the product name, process and other information.

Scoutbee’s supplier search interface with input criteria and longlist results

Scoutbee’s supplier search interface with input criteria and longlist results Source: Scoutbee [/caption] 2. Spend Analysis Companies undertake cost-benefit analyses to identify the best suppliers, requiring an efficient spend classification system for comprehensive results. Manual spend classification or even semi-automated classification falls short of the depth that an AI-driven solution can offer.

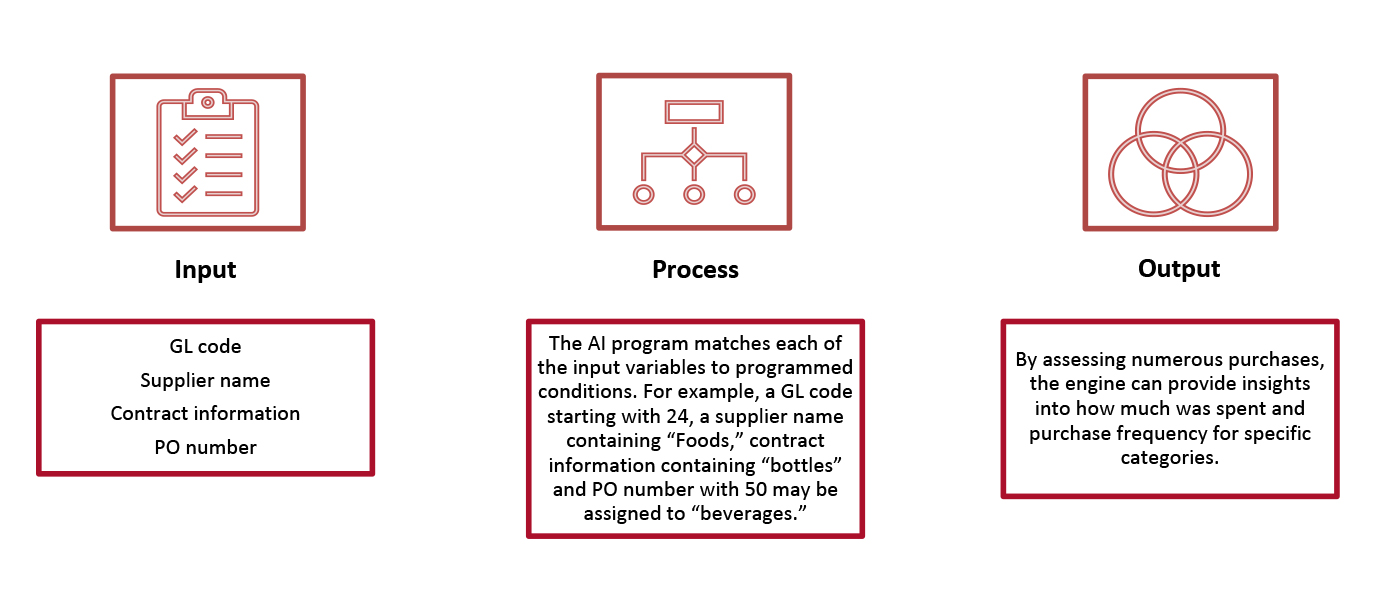

- Challenges: Matching supplier names, spending, purchase frequency and contract information from earlier purchases.

- AI application: Spend classification algorithms sift through line-item information and highlight keywords to link to spend categories by associating input variables, such as general ledger (GL) codes (codes assigned to financial entries in a firm’s accounting ledger), contract information, purchase order (PO) numbers and supplier names, using NLP. ML is then used to classify the output into specific categories. This technology can drill down to a granular level within product descriptions, suppliers or accounting/budgeting line-items and capture detailed data.

Figure 4. Using AI to Classify Spend Categories [caption id="attachment_148392" align="aligncenter" width="699"]

Source: Coresight Research[/caption]

Source: Coresight Research[/caption]

- Innovator: Established in 2000, ProcurePort provides cloud-hosted e-procurement software and services to companies across the food and beverage, healthcare and manufacturing industries. ProcurePort uses a structured spend analysis process to clean and analyze spend data. The spend analysis platform imports data from Excel or other comma-limited file formats and cleans it by flagging duplicate or incomplete entries.

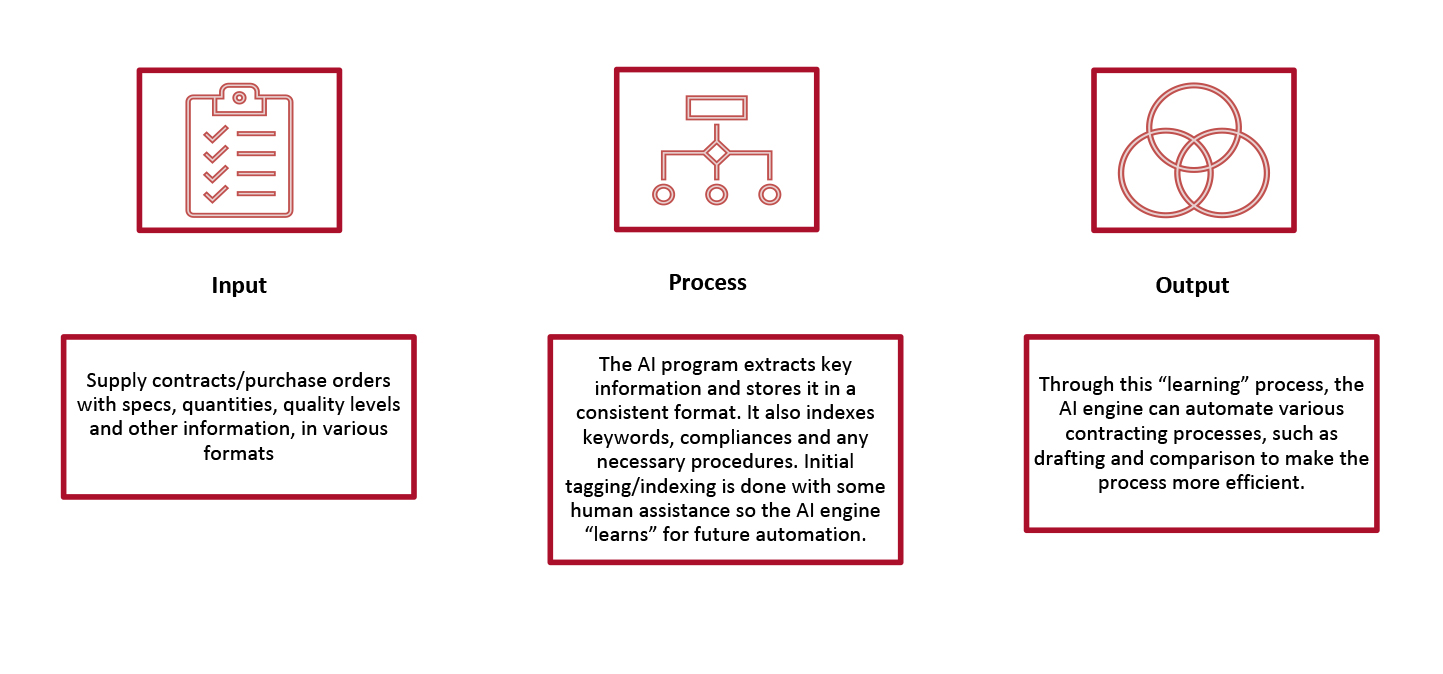

- Challenges: Ensuring contracts have the relevant language and terminology, maintaining unstructured contract databases, and risk assessment.

- AI application: Companies should save contracts in electronic format or convert scanned documents into text format with optical character recognition for contract lifecycle management (CLM) systems to read and analyze them. NLP can help extricate useful information from these documents. Users train NLP models by establishing sample documents in the interface, with specific annotations on each element before running the program on other contracts. Extracting important information and terms with NLP can assist firms in compliance, determining potential risks within contracts and highlighting items for review—helping them transition to sophisticated end-to-end sourcing systems.

Figure 5. Using AI to Examine, Formulate and Store Contracts [caption id="attachment_148393" align="aligncenter" width="700"]

Source: Coresight Research[/caption]

Source: Coresight Research[/caption]

- Innovators: Razor365 is a CLM application that automates the complete contracting process from requisitions to renewals and intermediate actions, including reviews, auto-drafting, negotiation, comparison, versioning, signing and execution. The platform uses AI to track deviations and map risks when various stakeholders make changes to drafts and flags them for review. The platform also uses AI to summarize billing or fulfillment obligations to communicate them to relevant teams.

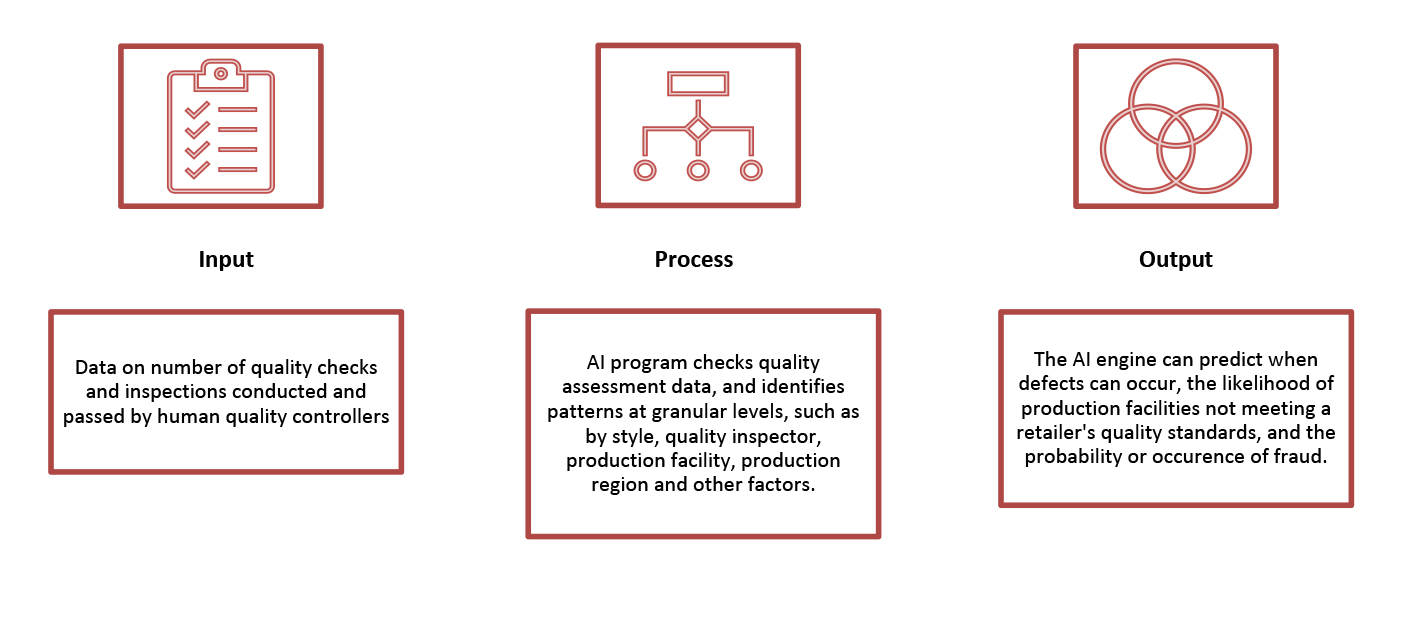

- Challenges: Quality control and compliance monitoring—crucial processes to reduce inefficiencies and deliver quality, low cost and speed to market—still largely rely on archaic, manual, paper-based processes on spreadsheets. This leaves global supply chains mostly disconnected and prone to lack of visibility, inefficiency, inaccuracy and risk.

- AI application: Automated compliance monitoring and inspection, and real-time data analysis and sharing can help promote transparency and equip firms to better prepare for and handle disruptions. AI programs can be developed to detect anomalies in production and identify areas open to potential human error or interference that could lead to a lack of compliance.

Figure 6. Using AI for Production Monitoring [caption id="attachment_148394" align="aligncenter" width="699"]

Source: Coresight Research[/caption]

Source: Coresight Research[/caption]

- Innovator: Founded in 2015, the Inspectorio platform digitalizes the quality control and compliance monitoring processes within the apparel, accessories and footwear supply chain using mobile, web and AI technologies. The platform employs AI to analyze data that has been entered into the system for predictive and prescriptive capability. This includes:

- Defect prediction: Inspectorio is able to predict the stages of the supply chain where potential product failures or defects will occur, based on data collected. While risk assessment has typically been dependent on the experience and knowledge of a single human inspector, Inspectorio transfers this function to an application that leverages a large amount of data analyzed through AI.

- Risk assessment: Inspectorio can identify the probability of a production site not meeting the quality standards of a particular buyer, and the potential future performance of that production facility, based on its historic performance. This allows large companies that typically need to inspect thousands of facilities to decide which ones require direct inspections and which can be trusted for self-assessment.

- Fraudulent behavior monitoring: Inspectorio’s technology can predict fraudulent behavior by inspectors, according to inspection results and how inspections are performed, by studying factors such as the time per inspection and how inspection results have been revised during the process. The platform can also analyze the historical performance of a facility and flag the risk of inspectors obscuring or falsifying inspection results.

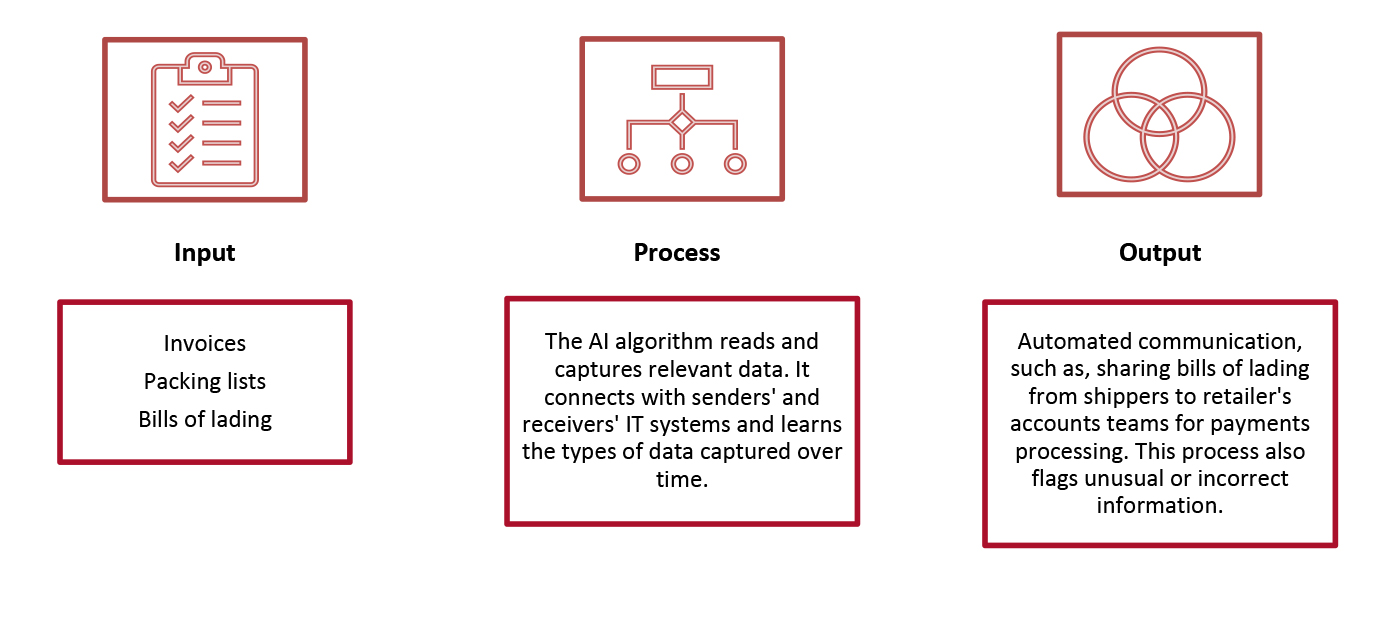

- Challenges: Managing multiple documents, communicating the right information in a timely manner, and making payments on time. Moreover, reviewing and processing invoices is a largely manual effort and is time-consuming. Without stringent checks in place, there is also a high risk of processing fraudulent invoices.

- AI application: AI algorithms can read, extract and input data from documents received to improve communication with stakeholders across the supply chain.

Figure 7. Using AI for Sharing Shipping Information and Payment Processing [caption id="attachment_148395" align="aligncenter" width="699"]

Source: Coresight Research[/caption]

Source: Coresight Research[/caption]

- Innovators: Founded in 2017, Rossum automates document-based communication between parties. The platform offers an AI-based document processing gateway that collects, processes and communicates documents to relevant parties. It uses computer vision to quickly read invoices, packing lists, bills of lading and other documents, and cognitive intelligence that mimics the human brain to capture data. It then provides intuitive assistance to users to help them validate and rectify the data. The platform connects with the companies’ as well as senders’ IT systems to automate document communication. It also includes tools to manage document traffic and generate analytics. For the automated communication to take place smoothly, accurate data capture is key and Rossum’s machine learning algorithms learn and improve each time they capture data and human users either correct the data or use what was captured.

What We Think

Supply chains have increasingly come under the spotlight as pandemic-led disruptions have exposed their vulnerabilities, leading companies to undertake a strategic overhaul of their sourcing operations. As retailers and brands need to work with numerous suppliers scattered internationally, each with varying degrees of scale, compliance and quality, managing sourcing processes is incredibly complex. Data captured between each of the parties is largely stored in siloes, blocking opportunities for sourcing and procurement teams to leverage unified insights and take efficient actions. AI can help alleviate these challenges and make sourcing more efficient. Implications for Brands/Retailers- Retailers need to leverage AI across multiple functions within the retail value chain to be able to derive economic cost savings and achieve revenue growth.

- Integrating repetitive functions with AI platforms will help reduce room for error, predict risk instances and prescribe corrective actions.

- Cutting out manual processes frees up time for personnel to spend on analyzing processes, managing disruptions and exploring strategies for efficiency.

- Building out processes with AI-based applications that integrate well across functions and platforms will help companies to grow toward a digitalized, cohesive supply chain and increase visibility across processes.

- Technology firms that can provide end-to-end services across the sourcing value chain will tend to benefit. Many of the end-to-end platforms are built for large firms with high-volume sourcing activities. Firms should be able to scale their platforms to meet the needs of smaller firms and take advantage of the current environment when companies are in need of adequate support and insights across the sourcing value chain.