Web Developers

In our report Supply Chain Sustainability: A Strategic Priority for Apparel Retailers and Brands, we discuss how an environmentally sustainable supply chain is particularly important for the fashion industry, as apparel manufacturers make extensive use of resources, chemicals and energy, and often operate a global supply chain, both of which can have a big impact on the environment. Moreover, the continuous expansion of fast fashion and online retailing is exacerbating the issue, as more clothes are produced, fulfilled and, in many cases, returned back to retailers, impacting carbon emissions and waste accumulation.

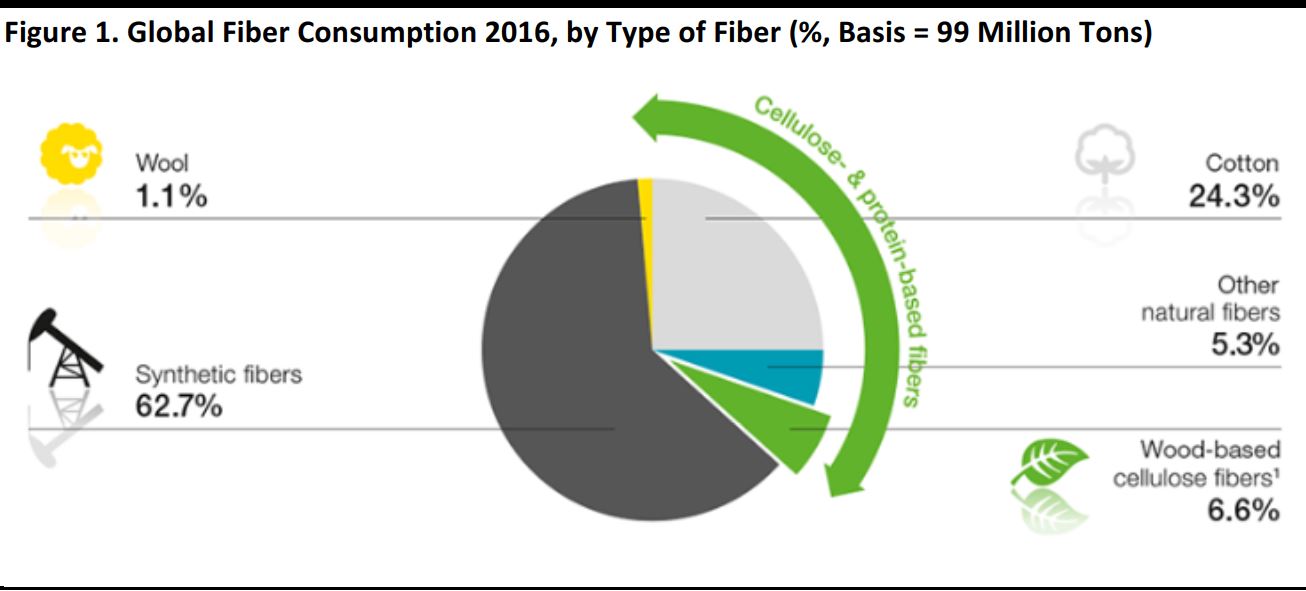

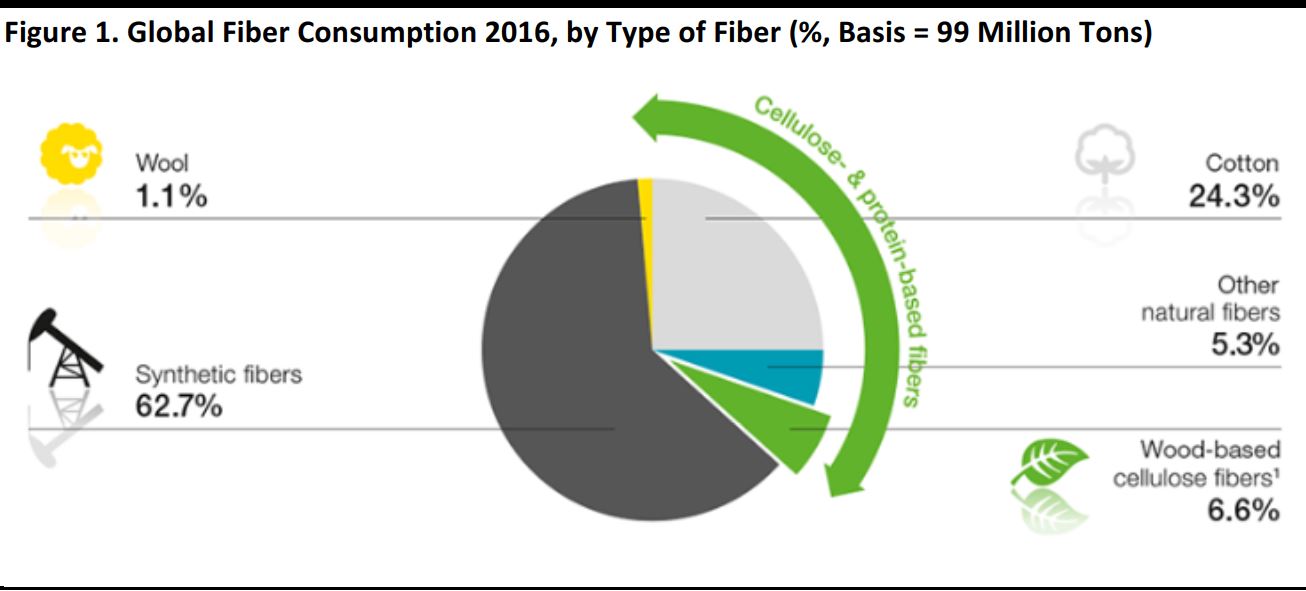

Beyond the environmental tax of manufacturing and transporting apparel, the low cost of petrol in recent years has led to the proliferation of the use of synthetic materials, made from petroleum derivatives, which accounted for 62.7% of global fiber consumption in 2016, according to estimates from fiber-producer Lenzing.

1 Wood-based and cotton inter-based cellulose fibers. Source: Lenzing/ICAC/CIRFS/TFY/FEB

As a result, a big focus for sustainable fashion is to source and use more eco-friendly raw materials such as sustainably-grown cotton, wood-based fibers and recycled synthetic materials, and many large apparel companies are moving in this direction. One example is Ralph Lauren, which instituted a new policy earlier this year, which prevents the company from sourcing wood-based fabrics that are connected to deforestation and unethical labor. Another example is Eileen Fisher, which has pledged to use the most sustainable fibers the company can source, discontinuing the use of rayon, a synthetic, and to recycle heavily as part of its Vision2020 initiative. In addition to large corporates, there is an increasing number of young companies that are entering the space with sustainable innovative offerings―Utterly and Reformation are just two examples that we have featured in our research. With this report, we continue our coverage on the topic, by profiling a business that focuses on producing sustainable organic fiber out of wild Himalayan nettle, while also advocating for the development of the local communities of Nepalese farmers who wild-harvest and process the nettle into fibers.

Source: Himalayan Wild Fibers (HWF)

Company Background

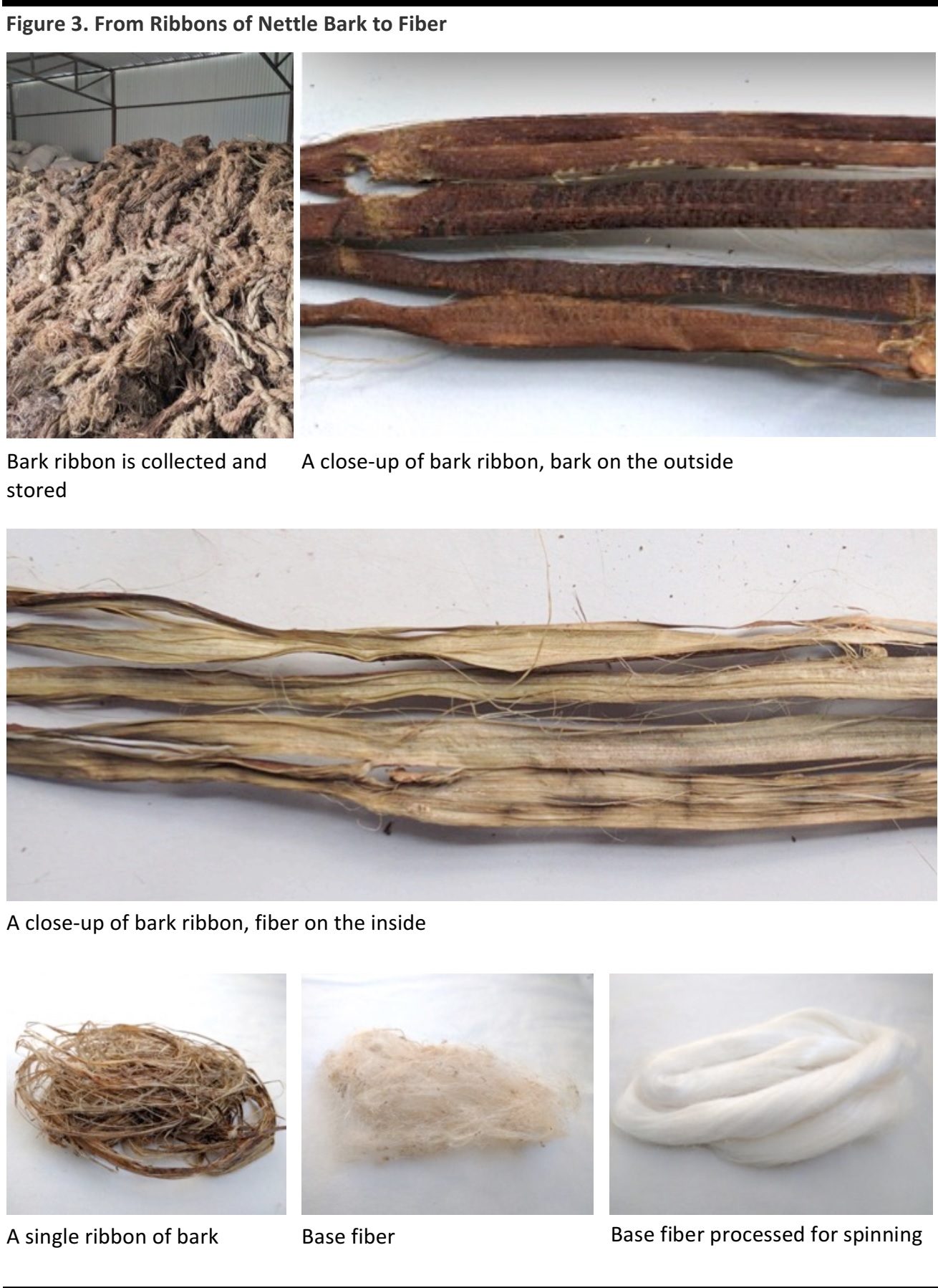

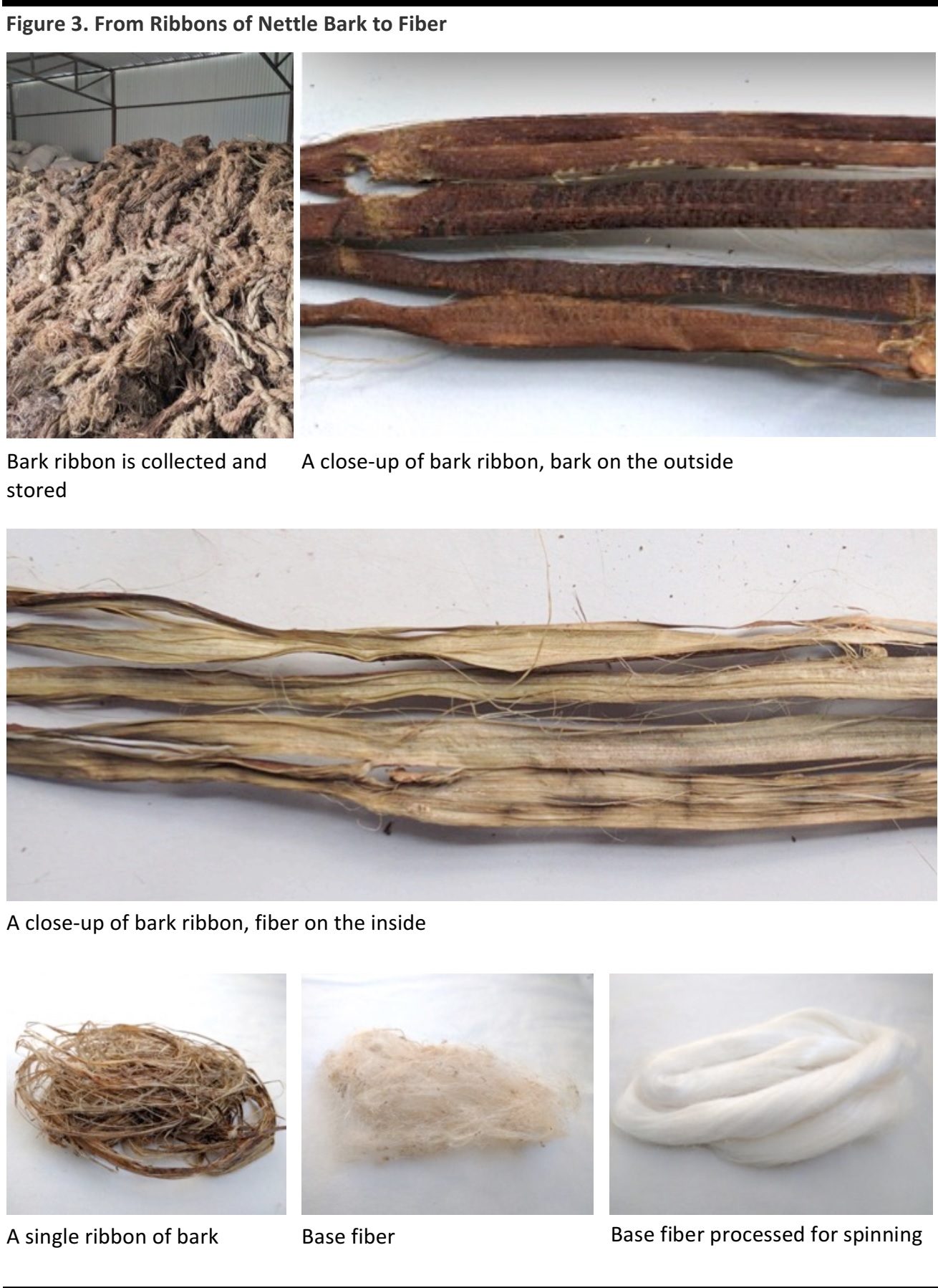

Himalayan Wild Fibers (HWF) is a socially-driven US enterprise with operations in Nepal that produces a textile fiber extracted from wild nettle growing in the mountain forests of the Himalayas, and sells it into global textile supply chains as a raw material input for the manufacture of high-end apparel and furnishings. The company purchases raw Himalayan nettle (ribbons of bark peeled from the plant) at fair-trade prices from subsistence farmers who wild-harvest the material during their off season, and employs workers for the nettle fiber extraction process, creating sustainable income for local communities. HWF operates with the triple bottom line in mind, a framework which evaluates the social, environmental (or ecological) and financial impact of a business, and with the goal of impacting the lives of thousands of Nepali families. HWF is committed to making significant contributions to a 501c3 non-profit organization dedicated to the support and development of Himalayan communities and to ensure that the long-term benefit of wild Himalayan nettle fiber production remains with Himalayan villagers. Source: Himalayan Wild Fibers (HWF)

Source: Himalayan Wild Fibers (HWF)

Why Wild Himalayan Nettle?

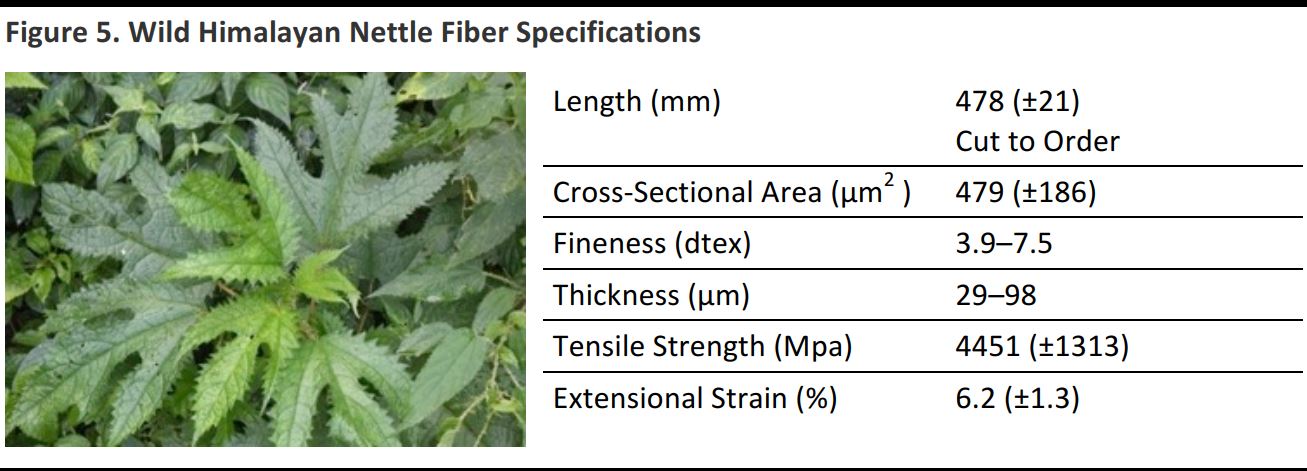

Nettles, famous for the stinging quality of their leaves, are plants that grow freely in the wild, usually on land unsuitable for other crops. Himalayan nettle grows in forests at high altitudes in Nepal and India and its extensive root system plays a critical role to the conservation of the soil, as well as increasing the value of the standing timber to help stem deforestation. From a sustainability perspective, Himalayan nettle offers unique benefits when used as a textile fiber that differentiate it from cultivated common nettle or from wild nettle growing in other regions of the world. First, the wild-harvesting of Himalayan nettle is good for the surrounding environment because it strengthens the rhizome root system and stabilizes the soil, which reduces landslides in the Himalayan mountain forests. Common nettle, in contrast, is harvested from the roots, which does not yield the same benefits for the surrounding soil ecosystem. In addition, harvest increases annual regrowth, which creates large masses of green leafy plants to absorb CO2. Himalayan nettle is one of the longest natural fibers in the world, which sets it apart from other nettle or bast fibers. Wild Himalayan nettle fibers offer flexibility and bend, and once processed, the fibers look and have similar properties to linen. However, they are considered more lustrous, stronger and less susceptible to wrinkling, because of the hollow structure of the fiber. Due to the qualities and the benefits associated with the harvesting of wild Himalayan nettle, the use of its fibers is a sustainable alternative to most synthetics, and even cotton, which is why HWF decided to focus on producing fibers from the plant.Processing Nettle into Fiber

HWF set up a fiber-extraction operation in Kathmandu using basic, locally available materials and low-cost machinery. The operation is staffed by local people and built with sustainability in mind. For example, washing water is recycled multiple times to keep net usage low, and waste wood from the carpentry industry is used for fuel. According to HWF, the fiber-extraction process uses about 75 liters of water per kilogram of fiber, and the team expects that usage to drop by as much as 70% once the system is upgraded. In contrast, it can take more than 20,000 liters of water to produce one kilogram of cotton, according to the WWF.

Source: Himalayan Wild Fibers (HWF)

Uses and Applications of Himalayan Nettle Fiber

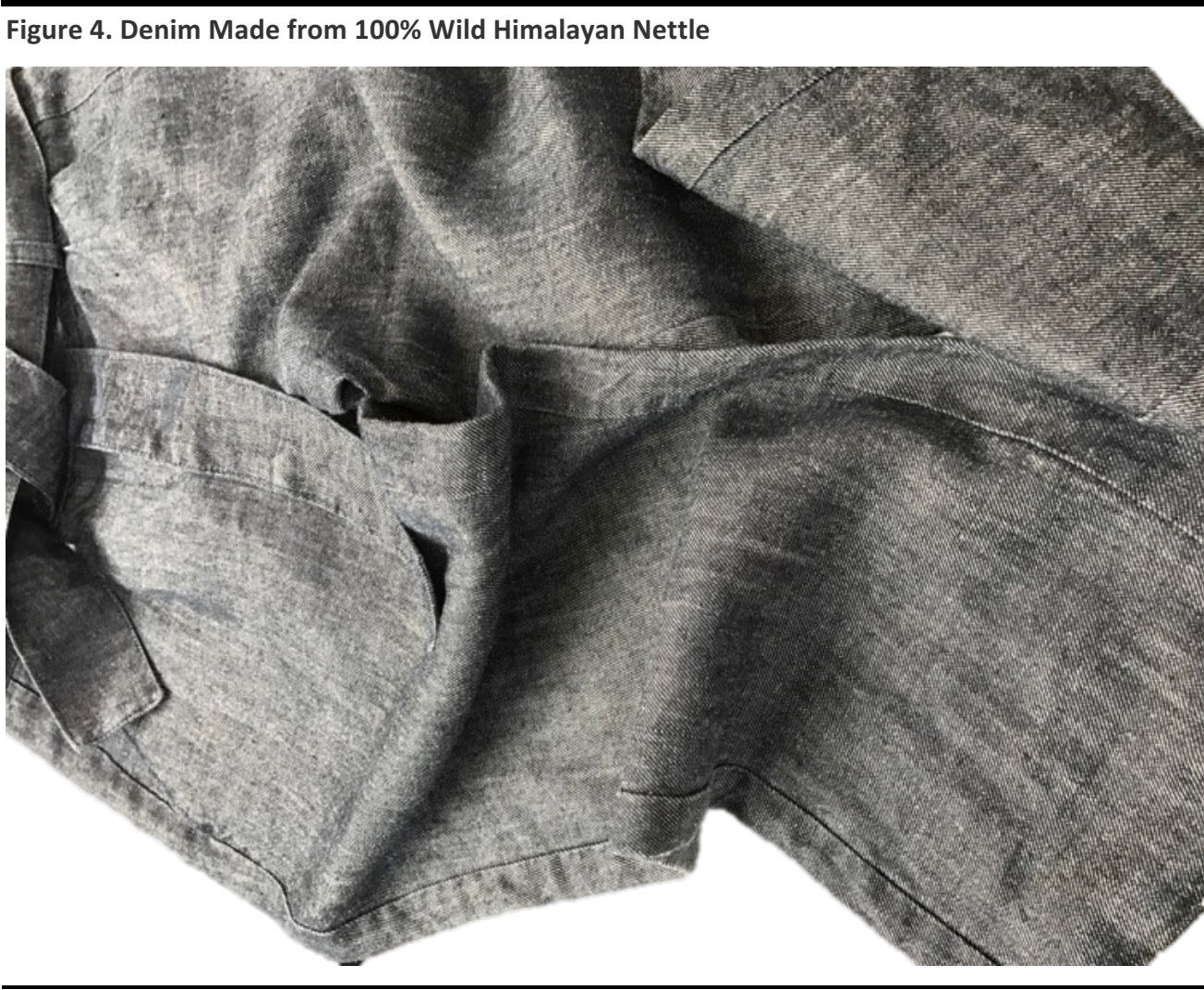

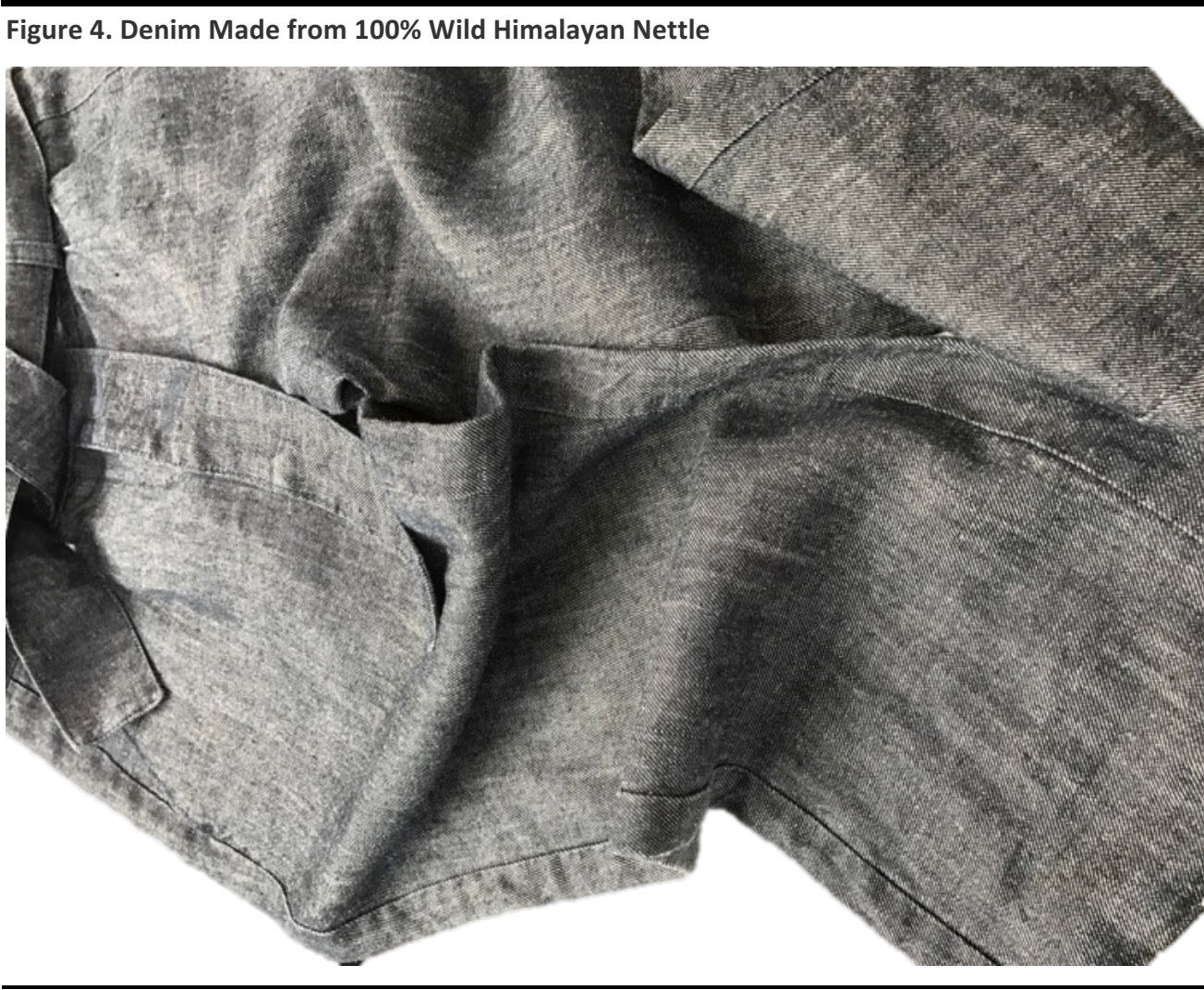

After HWF processes the fibers in Nepal, it exports them to be used in the manufacture of luxury yarns and fabrics. These, in turn, are used by apparel companies and designers to develop and produce garments including denim, knitwear and woven wear. Brands such Eileen Fisher, Stella McCartney, Hermes and Chanel have expressed interest in using the raw material for their products.

Source: Himalayan Wild Fibers (HWF)

While HWF’s operation is impressive in its aim to support local communities in Nepal and introduce sustainable innovation in fashion, it is certainly not the first company that has turned to nettle fibers:- Camira, a furnishing textile producer, partnered with De Montfort University in a project to use common nettle as the raw material fiber input for a new environmental textile used for upholstery. The collaboration resulted in the discovery of a new method for extracting fibers from nettle stems using enzymes and a venture called STING: Sustainable Technologies in Nettle Growing.

- Brennels, was a Dutch fashion label which focused on producing apparel from environmentally-friendly fabrics. The company cultivated its own nettle farm, where the team experimented with the growing and fiber-extraction processes. Brennels then worked with partners, including Camira, to develop nettle yarns and find applications for the nettle fibers.

Source: Himalayan Wild Fibers (HWF)

Source: Himalayan Wild Fibers (HWF)