albert Chan

What’s the Story?

Fast-changing consumer demands and tastes have pushed brands and retailers to innovate. Many are adopting new technologies to reduce production times and offer personalized products. 3D printing, also known as additive manufacturing, is one technology that is helping brands and retailers to improve operational efficiency and offer personalized products.

3D printing is the process of making a physical object from a three-dimensional digital model. This involves slicing three-dimensional digital designs into layers and then using the material additively to build up a product layer by layer. This technology is being increasingly adopted across various industries, particularly in the apparel, footwear, furniture and jewelry categories.

We identified four ways to leverage 3D printing in the manufacturing process:

- For prototyping

- To manufacture products on demand

- To create a component of the final product

- To manufacture the whole product

There are two ways to test this technology. Some companies choose to keep the 3D printing process in-house. Others have partnered with a technology solution provider to explore the potential for 3D printing to optimize their manufacturing processes.

In this report, we focus primarily on the application of 3D printing in the retail industry. We discuss the process and benefits of 3D printing and showcase select application cases from the apparel, cosmetics, footwear and furniture markets.

Why It Matters

In the wake of Covid-19, technology implementation has been a priority for many companies. There are also many technology options for brands and retailers to leverage in their retail supply chain.

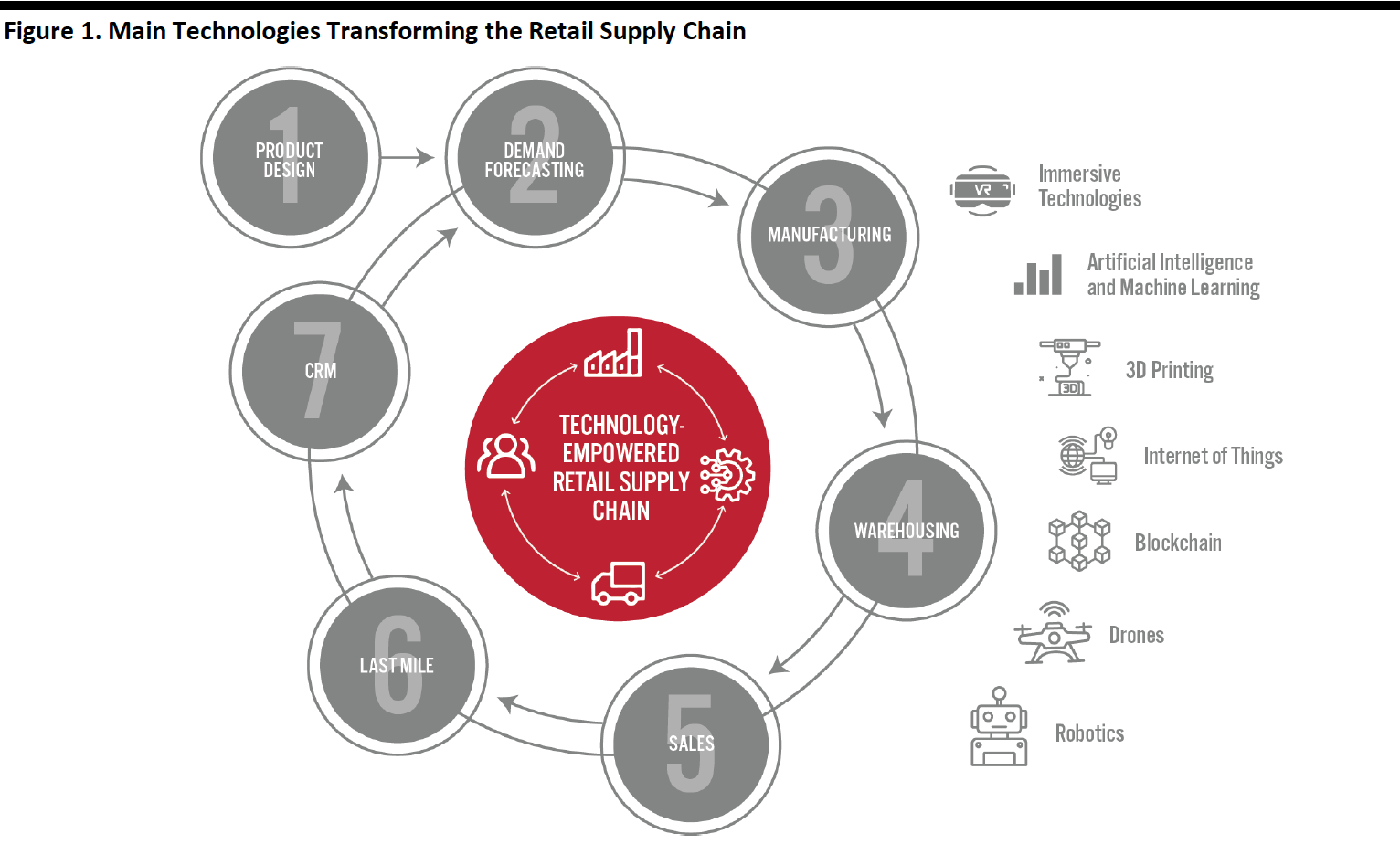

We identify the seven major components of a retail supply chain in Figure 1 below, and the different technologies that can support processes at each stage—from product design to end consumer. 3D printing technology is featured at the manufacturing stage.

[caption id="attachment_117640" align="aligncenter" width="700"] Source: Coresight Research[/caption]

Source: Coresight Research[/caption]

3D printing is an important and increasingly compelling technology in the manufacturing process. The global 3D printing products and services market is currently estimated at $15.8 billion, with predictions of it reaching $35.6 billion in 2024, reflecting a CAGR of 22.5%, according to Wohlers Associates. However, the sub-market that relates to the retail industry and services brands and retailers is only likely to account for a small portion of this market value.

According to an EY survey of 900 companies, the percentage of businesses that have experience of additive manufacturing increased to 65% in 2019, up from 24% in 2016. Moreover, the same survey indicated that 18% of surveyed companies already using it to produce end-use products and 14% use the technology to manufacture spare parts. As companies become more comfortable with this technology, they are more likely to incorporate it in the production process. We expect to see continued growth in the implementation of 3D printing technology.

3D Printing on the Rise: A Deep Dive

The 3D Printing Process

3D printing, also known as additive manufacturing, can be simply described as the sequential building of a three-dimensional solid object by successively injecting layers of materials following a digital model and using a 3D printer.

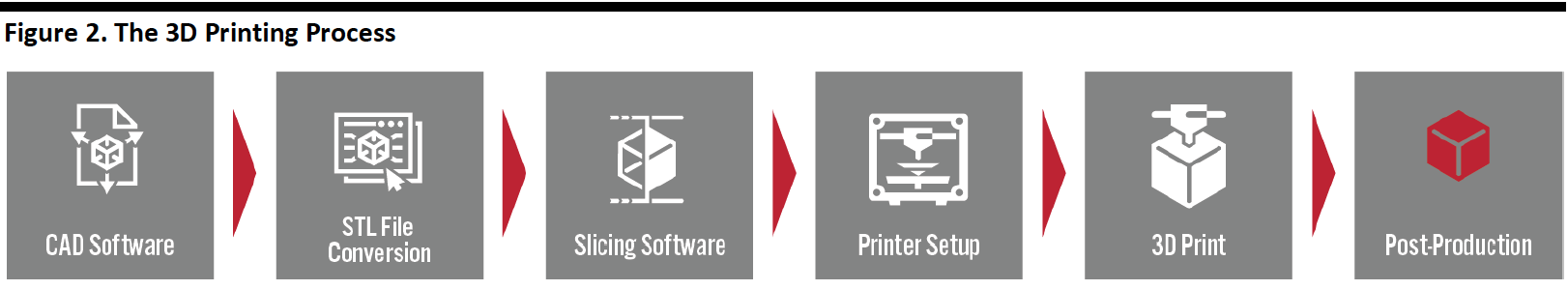

The 3D printing process varies widely according to the type of material used. Typically, there are six steps involved in the process:

- Using computer-aided design (CAD) software to produce a 3D model

- Converting the CAD drawing to the standard tessellation language (STL) format. This is a common file type accepted by most 3D printers

- Transferring the STL file to the computer that controls the 3D printer and adjusting the printing setting using a slicing software that converts the STL format model into printer commands

- Setting up the 3D printer, including refilling the polymers, binders and other materials that the printer uses

- Launching the (almost) automatic build process

- Conducting post-production procedures on printed items

Source: Coresight Research[/caption]

Source: Coresight Research[/caption]

The Benefits of 3D Printing

3D printing is a promising technology for transforming the manufacturing aspect of the retail supply chain. We believe this technology can improve supply chain and operations processes in the following ways:

- Efficiency—minimizing delays in sample design and production reduces time-to-market. 3D printing is likely to cut out the back-and-forth sample production, optimize design stages and bring production closer to consumers to reduce complications in logistics.

- Personalization—brand and retailers can leverage this technology to offer personalized products based on customers’ requirement.

- Decentralization—more opportunities to innovate in the development process gives production teams greater scope and flexibility.

- Sustainability—brands and retailers can minimize manufacturing waste. 3D printing allows materials to be repurposed as well as and lowering initial inventory requirements.

3D printing likely makes it easier for companies to achieve nearshoring and relocate production closer to consumers. It can lower the likelihood of communication errors, improve corporate control over intelligence property and increase go-to-market speeds. In the future, perhaps consumers will be able to visit a 3D printing store to personalize branded items, instead of visiting a specific brand location.

3D Printing Vendors

A number of companies are now manufacturing and selling 3D printers, as they form an essential part of the printing process. Technology vendors are also focusing on developing software that improves the 3D printer workflow.

Figure 3 highlights select companies serving the 3D printing industry.

Figure 3. Select 3D Printing Vendors [wpdatatable id=503]

Source: Company websites/Coresight Research

In addition to purchasing in-house 3D printers, companies can also work with 3D manufacturing partners. Several of the companies mentioned above offer their 3D printing manufacturing services globally.

Brands and retailers can also work with startups to test the technology. For example, Shapeways, a New York-based 3D printing marketplace and service provider, enables users to upload CAD files through its website and choose from over 55 printing materials—providing an accessible and affordable way to leverage this technology. Using the Shapeways platform, businesses can also connect with 3D printing service providers and sell final products directly to consumers. In 2019, the company celebrated 3D printing 10 million items.

Consumer-Goods Firms Deploy 3D Printing

In the apparel, beauty, footwear and furniture markets major brands have deployed 3D printing, as we discuss in the subsequent sections. However, we note that these ventures tend to have been fragmented and sporadic, rather than a consistent or sustained application of 3D printing to existing businesses.

3D Printing: Apparel

Current technology limitations mean that using 3D printing to manufacture consumer-ready clothing is complicated and costly to achieve. A breakthrough from Stratasys is indicative of innovations that could break down this commercial barrier.

- Stratasys announced its partnership with fashion designers Ganit Goldstein and Julia Koerner for its direct-to-textile PolyJet Technology on September 11, 2020. During the 2019 New York Fashion Week, Stratasys showcased its ability to add polymers straight onto fabric. Designers can leverage this technology to create multi-color 3D printed parts and combine them into a finished apparel item.According to Stratasys, “this allows for extra movement within the fabric, but also enables full gain between the capacity and material thickness that is printed on top of the fabric”. The technology still needs to be widely tested for commercial use, but it does signal a potential future of digitalized end-to-end design workflow. If the pilot is successful and implementation costs are reasonable, we expect to see apparel companies incorporate 3D printing into their manufacturing process.

3D-Printed ARID Collection from Julia Koerner

3D-Printed ARID Collection from Julia KoernerSource: Stratasys[/caption]

3D Printing: Footwear

The footwear industry has been experimenting with 3D printing in production for several years. Many companies are already familiar with using this technology to produce parts of their shoes for and are bringing more products to market this way.

Most often, companies use this technology to produce prototype or parts of the final product, instead of producing final footwear products in their entirety.

- Adidas was among the first retailer to use this technology in shoe production. In 2016, Adidas gave medal winners at the Rio de Janeiro Olympics 3D-printed Futurecraft 4D sneakers as a gift. In 2018, Adidas announced its collaboration with Silicon Valley-based 3D printing company Carbon to release its Futurecraft 4D range. The production time for a single midsole for Adidas Futurecraft 4D sneakers could be cut to from 90 minutes to 20 minutes with further advances in 3D printing, according to Carbon.Adidas has subsequently released a number of sneakers under the 4D run series, all with a 3D-printed-midsole. On September 4, Adidas released its X90004D sneaker featuring a 3D-printed-midsole for $200. This marks another step by the brand toward commercializing 3D printing technology.As the company become more comfortable with this technology, we expect to see wider application of 3D printing in its shoe production process.

Adidas X90004D Sneaker

Adidas X90004D SneakerSource: Adidas[/caption]

- New Balance is also testing this technology and hopes to keep some of its manufacturing in the United States and the United Kingdom. It partnered with Formlabs, a startup that offers 3D printers, to kit out one of its factory’s in Massachusetts. However, the challenge has been achieving consistent quality across printed items and Formlabs is working on developing more reliable 3D printers. In October 2019, the company also partnered with the operating platform Unmade, which we discuss later.

3D Printing of Cosmetics

3D printing also has a place in cosmetics industry, both for research purposes and commercial use.

On the research side, companies have developed 3D bioprinting technology that can create 3D-printed skin.

- In August 2020, HK inno.N, a pharmaceutical company based in South Korea, announced its plans to use artificial, 3D-printed skin to test new autoimmune and skin-care drugs.

On commercial side, cosmetics firms use this technology in various ways.

- Chanel has been this technology to manufacture parts of its mascara brush Le Volume Revolution since 2018.

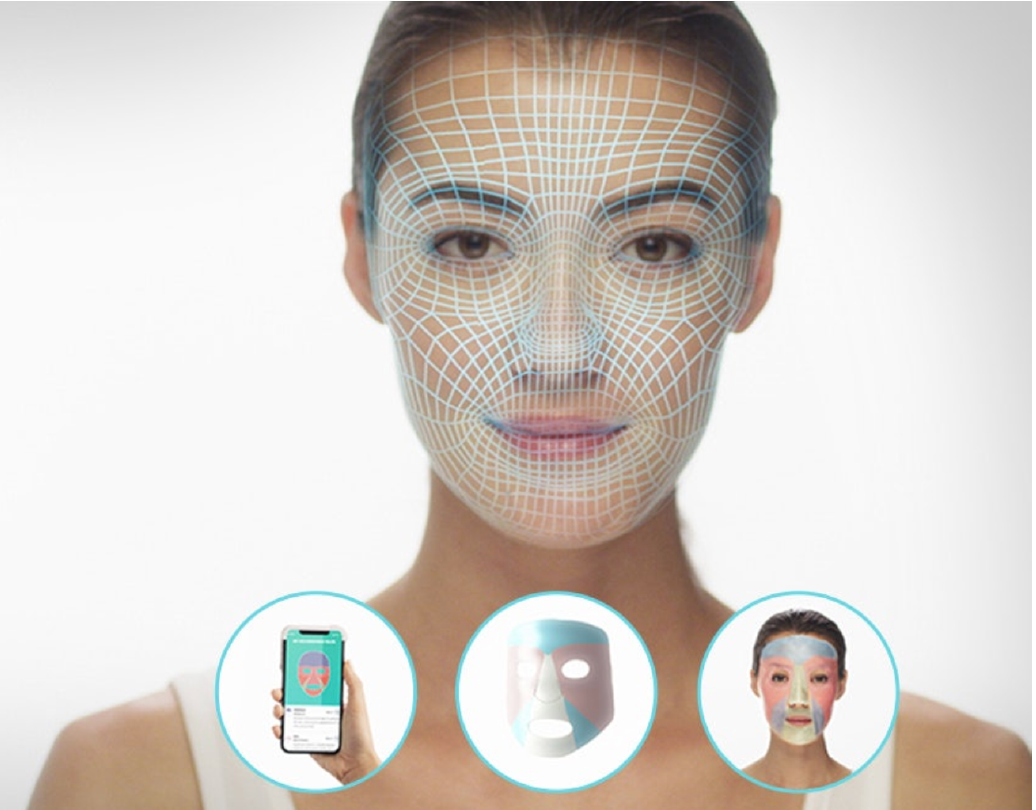

- Neutrogena presented its MaskiD innovation in 2019. The cosmetic company designed a face mask crafted to fit the wearer’s face and infused with customized ingredients. To use this product, customers take a selfie in the MaskiD app and select the desired treatment for each facial area. Based on that information, the company uses micro-3D printing to replicate the exact shape of the customer’s features and add the relevant treatment ingredient to the correct area of the mask.

MaskiD

MaskiDSource: Neutrogena[/caption]

3D Printing in Furniture

From design to production, furniture manufacturers are also leveraging this technology to create innovative furniture offerings. Large-scale 3D printers and advanced CAD software make it possible to produce a complete piece of furniture or home accessory. But in some cases, manufacturers are combining traditional manufacturing and 3D printing to create personalized items. Besides, using 3D printing technology can reduce waste and minimize the environmental impact of furniture manufacturing processes.

- Based in San Francisco, startup Model No. Furniture was founded in 2019. The company leverages eco-friendly materials and 3D printing technology to produce furniture. It adopts a create-on-demand business model, allowing shoppers to customize their purchases on its website. The company offers a variety of products including bins, coffee tables, side tables and vases.

Customization options for a Coffee Table on the Model No. Furniture website

Customization options for a Coffee Table on the Model No. Furniture websiteSource: Model No. Furniture[/caption]

- Industry leader IKEA has been testing this technology for some time, principally in the creation of product parts or personalized items. The company is set to release a customized ergonomic chair called Ubik—designed specifically for video gamers—in 2020. The idea was developed in 2018 when IKEA partnered with 3D printing solution provider UNYQ. Customers scan their body using a smartphone to customize the Ubik chair. Users will then receive two separate parts that adapts to their body and the chair base. The collection has not yet been released as of September 2020.

Adding 3D-printed parts to the Ubik chair from Ikea

Adding 3D-printed parts to the Ubik chair from IkeaSource: 3D Natives/UNYQ[/caption]

3D Printing in Jewelry

Metals are among the most popular materials used in 3D printing and the technology is ideal for jewelry manufacturing. This is perhaps one of few sectors that use 3D printing to make final products.

Typically, brands and retailers either fully 3D-print finished goods or use the technology to customize parts of the final products. Either way, shoppers are likely to personalize items in the process.

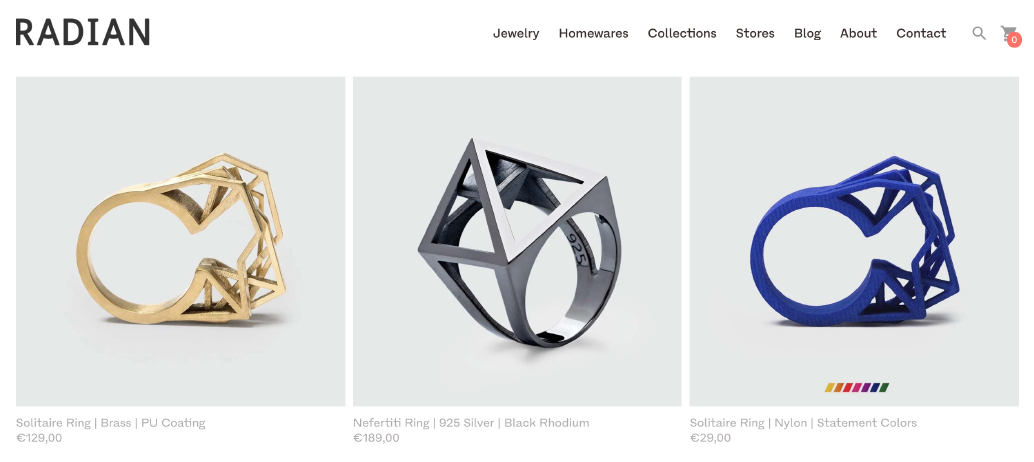

- RADIAN specializes in 3D-printed jewelry. It sells 3D-printed bracelets, earrings, homeware products, necklaces and rings. Its rings are available in various materials, from nylon to solid 585 yellow gold.

RADIAN rings on its website

RADIAN rings on its websiteSource: RADIAN[/caption]

- Nervous System is a design studio that focuses on applying 3D printing in art. Founded in 2007, the studio offers a variety of products from jewelry to houseware. Customers have the choice to engage in the design process and personalize items online. The company’s work has been showcased in the permanent collection of museums, including the Museum of Modern Art in New York.

Technology Application: Unmade

Founded in 2013 and headquartered in London, Unmade is an operating platform that enables fashion and sportswear brands to “connect demand directly to production” to build more efficient and responsible manufacturing processes.

What We Think

3D printing is widely applicable across various sectors and for different purposes. While many brands and retailers have produced 3D-printed products, product parts or personalized offerings, very few have proceeded to mass production.

The legacy, mass-market brand owners mentioned above have undertaken very limited ventures into 3D printing, such as with one high-profile product and with no apparent follow-up in the subsequent months or years. While these ventures have been high profile and have often generated significant press response, the absence of consistent deployment of, or multiple product launches in, 3D printing by mainstream names in consumer goods suggests that they do not yet see meaningful impact or major use cases for the technology in their businesses. Consequently, while we expect niche demand for 3D printing to remain, we do not yet see it disrupting industries and sectors in the mass market.

As the technology evolves and becomes more cost-effective, 3D printing has the potential to take on a more consistent and mainstream place in optimizing retail supply chains.

Implications for Brands/Retailers

- Brands and retailers can incorporate 3D printing into their manufacturing process, especially for prototyping, to reduce lead times and increase operational efficiency.

- 3D printing can help companies establish domestic production to mitigate impacts from international trade disputes and reduce the environmental impacts of shipping.

- Firms can create personalized products for customers either by fully 3D-printing final products or combining traditional production with 3D printing.

Implications for Technology Vendors

- Companies should design solutions that address operational efficiency needs and offer enhanced personalization.

- There are opportunities for collaborations with brand and retailers to test and develop new 3D printing technology.

- Research and development of innovative printing technologies and materials is needed to help scale production and lower costs.